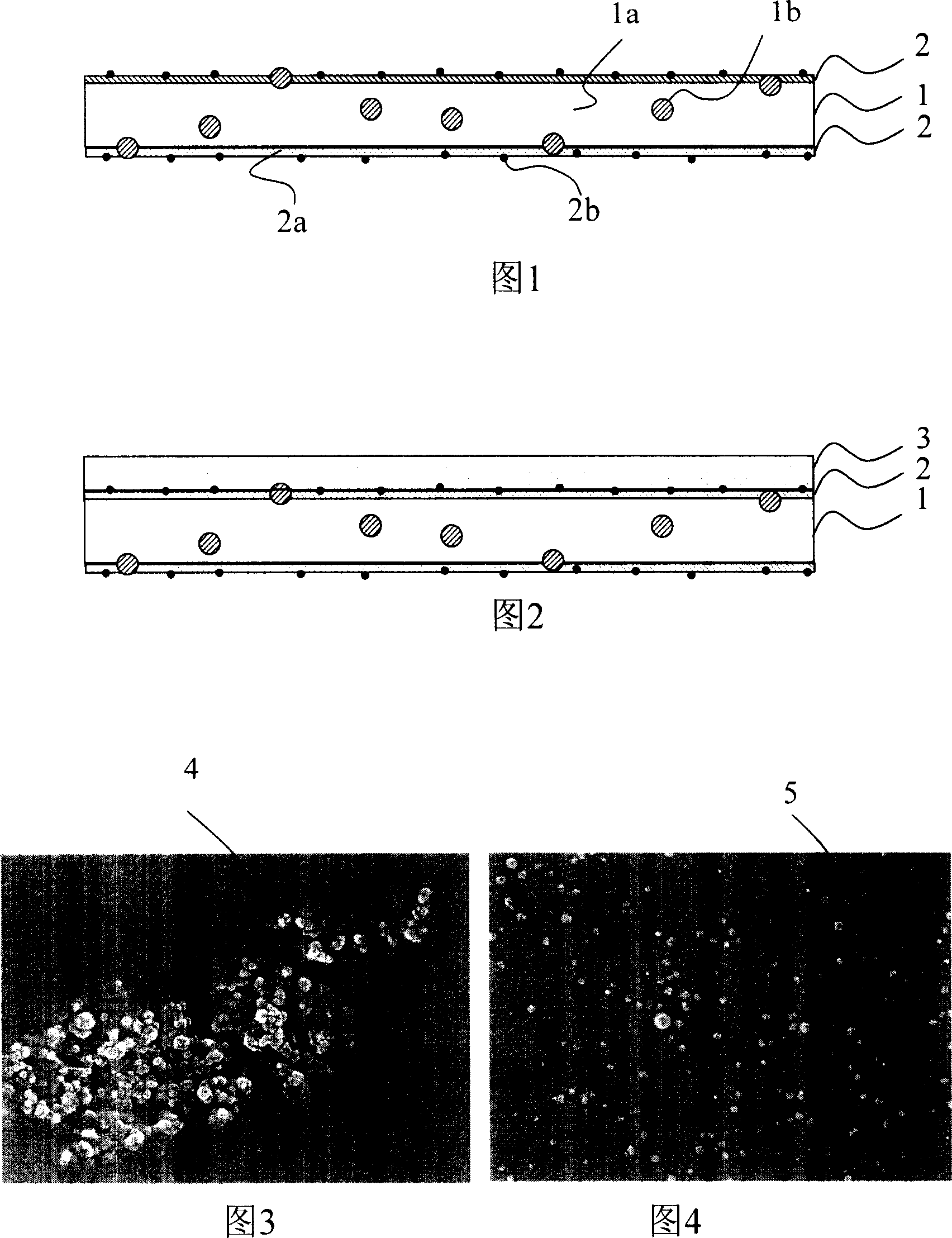

Aqueous applying liquid composition for optical polyester film

A polyester film and coating technology, which is applied in the field of optical polyester film water-based coating liquid composition, can solve the problems of good adhesion, poor adhesion of substrate PET polyester film, poor adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

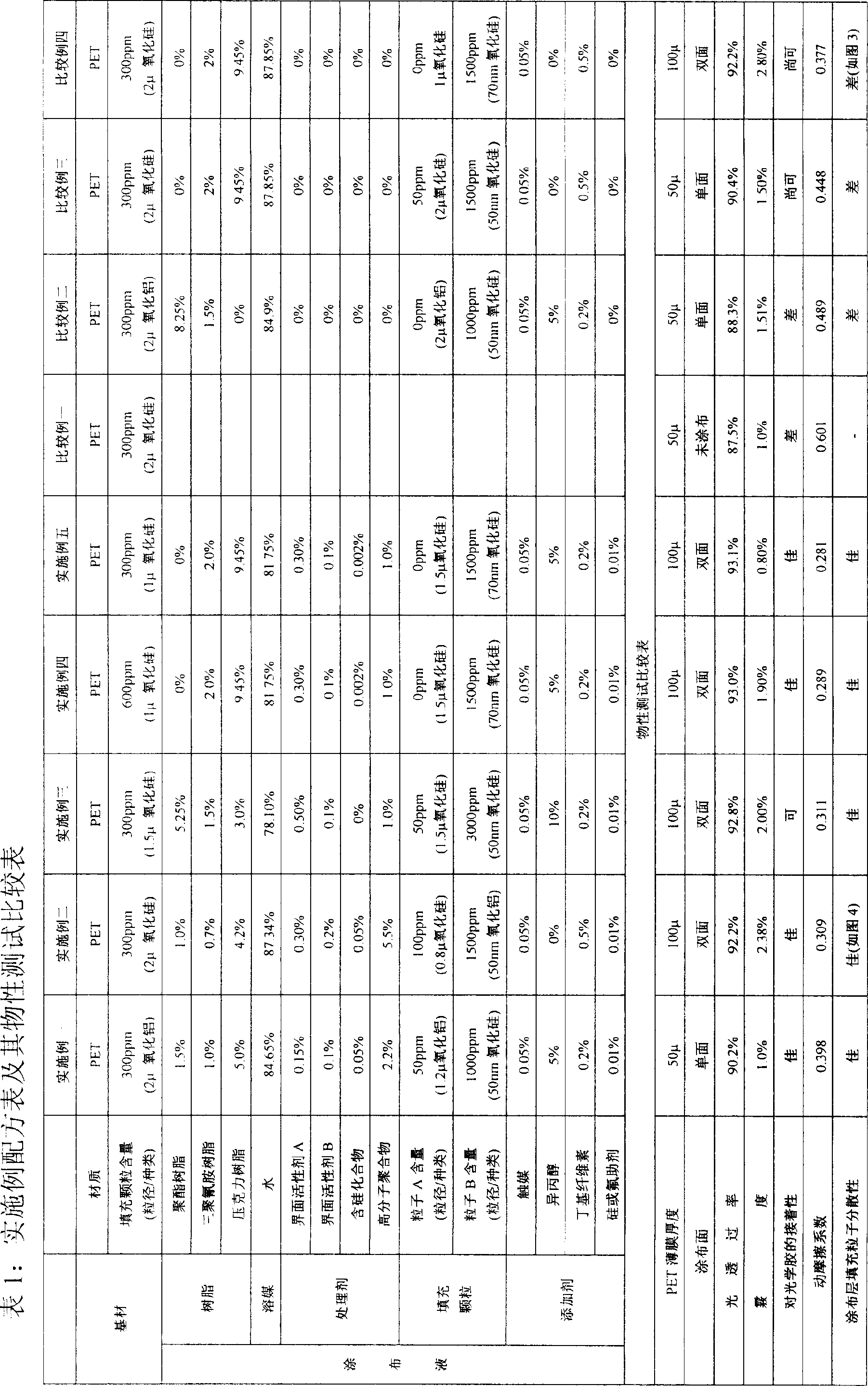

[0048] After fully drying the PET pellets containing alumina-filled particles with an average particle size of 2.0 μ (1b in Figure 1), they are fed to an extruder to be melted and extruded, and cooled and solidified by a cooling cylinder with a surface temperature of 25°C, thus obtaining unstretched The PET Sheet is stretched longitudinally at a draw ratio of 4 times after heating, and then coated on one side. The coating solution contains

[0049] 1.5wt% of polyester resin, 1.0wt% of melamine resin and 5.0wt% of acrylic resin are mixed as resin, and 0.15wt% of surfactant A, 0.1wt% of surfactant B, 0.05wt% of surfactant % silicon-containing compound and 2.2wt% high molecular weight polymer as the treatment agent, the particles to be treated are 1.2μ alumina particles A and 50nm silicon oxide particles B as filling particles, add 84.65wt% water for surface treatment Finally, mix and stir 0.05% catalyst, 5wt% isopropanol and 0.2wt% butyl cellulose to form a coating solution, whi...

Embodiment 2

[0051] Its formula consists of fully drying PET pellets containing silica-filled particles with an average particle size of 2.0μ (1b in Figure 1), feeding them to an extruder to melt and extrude them, and passing through a cooling cylinder with a surface temperature of 25°C to cool and solidify. The unstretched PET Sheet obtained in this way is longitudinally stretched at a draw ratio of 4 times after heating, and then single-sided coated. The coating solution contains

[0052] 1.0wt% of polyester resin, 0.7wt% of melamine resin and 4.2wt% of acrylic resin are mixed as resin, and 0.30wt% of surfactant A, 0.2wt% of surfactant B, 0.05wt% of surfactant % silicon-containing compound and 5.5wt% high molecular weight polymer as the treatment agent, the treated particles are 0.8μ silicon oxide particle A and 50nm silicon oxide particle B as filling particles, add 87.34wt% water for surface treatment After adding, 0.05% catalyst and 0.5wt% butyl cellulose were mixed and stirred evenly...

Embodiment 3

[0054] Its formula consists of fully drying the PET granules containing filler particles with an average particle size of 1.5μ, feeding them to the extruder for melting and extruding, and cooling and solidifying through a cooling cylinder with a surface temperature of 25°C, so as to obtain an unstretched PET Sheet. After heating, it is stretched longitudinally at a draw ratio of 4 times, and then double-sided coated. The coating solution contains

[0055] 5.25wt% of polyester resin, 1.5wt% of melamine resin and 3.0wt% of acrylic resin are mixed as resin, and another 0.50wt% of surfactant A, 0.1wt% of surfactant B and 1.0wt% % high molecular polymer as the treatment agent, the particles to be treated are 1.5μ silicon oxide particles A and 50nm silicon oxide particles B as filling particles, add 78.1wt% water for treatment, and finally add 0.05% catalyst, 10wt% of isopropanol and 0.2wt% of butyl cellulose were mixed and stirred evenly to form a coating solution, which was evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com