Method for preparing nitrogenous graphitized hollow carbon microspheres

A technology of graphitization and hollow carbon, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of cost increase and complicated preparation process, and achieve the effect of low cost, simple preparation process and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

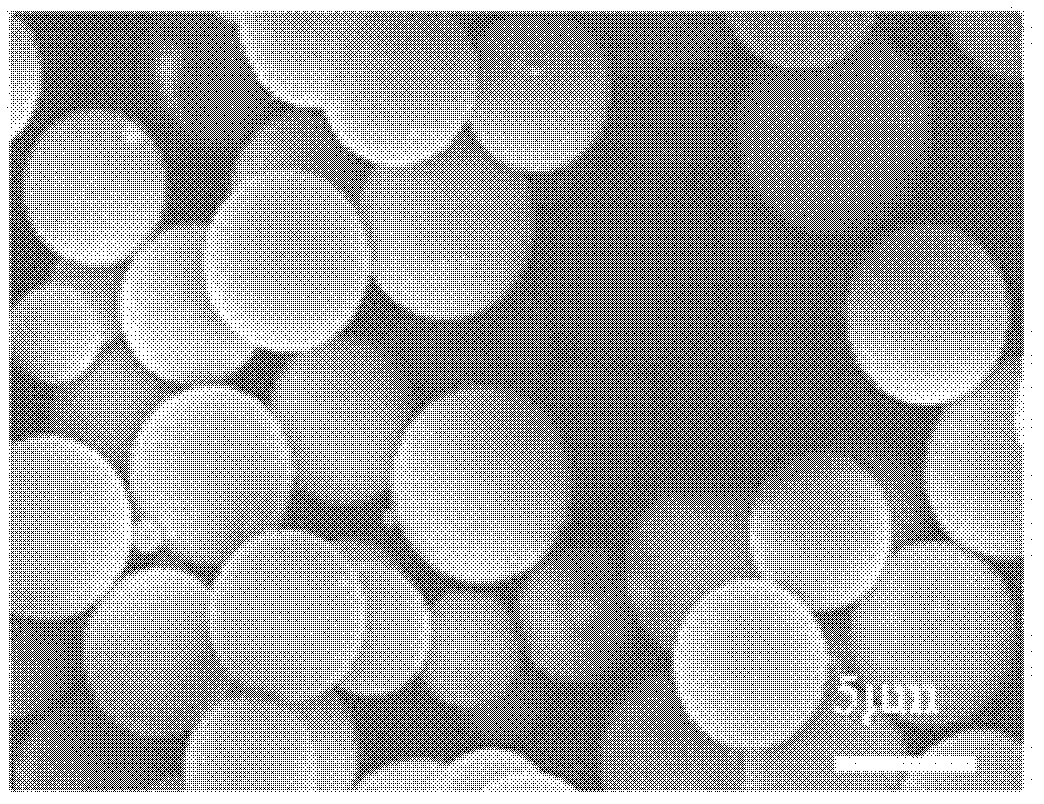

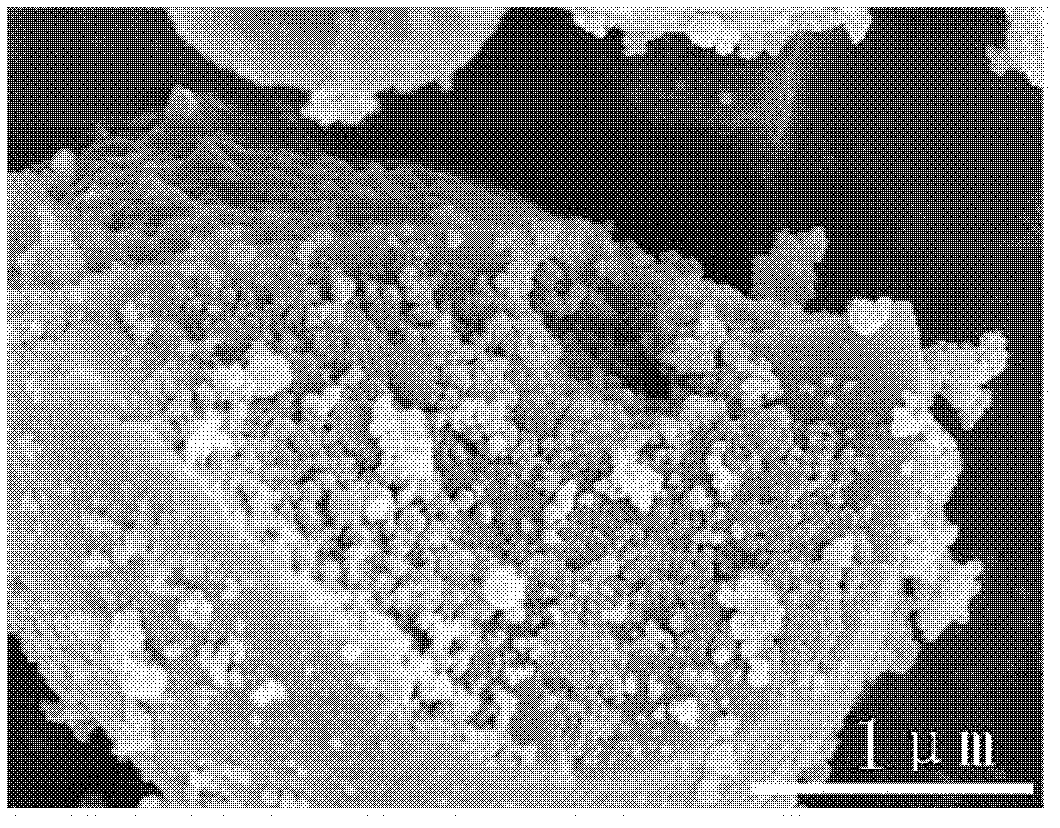

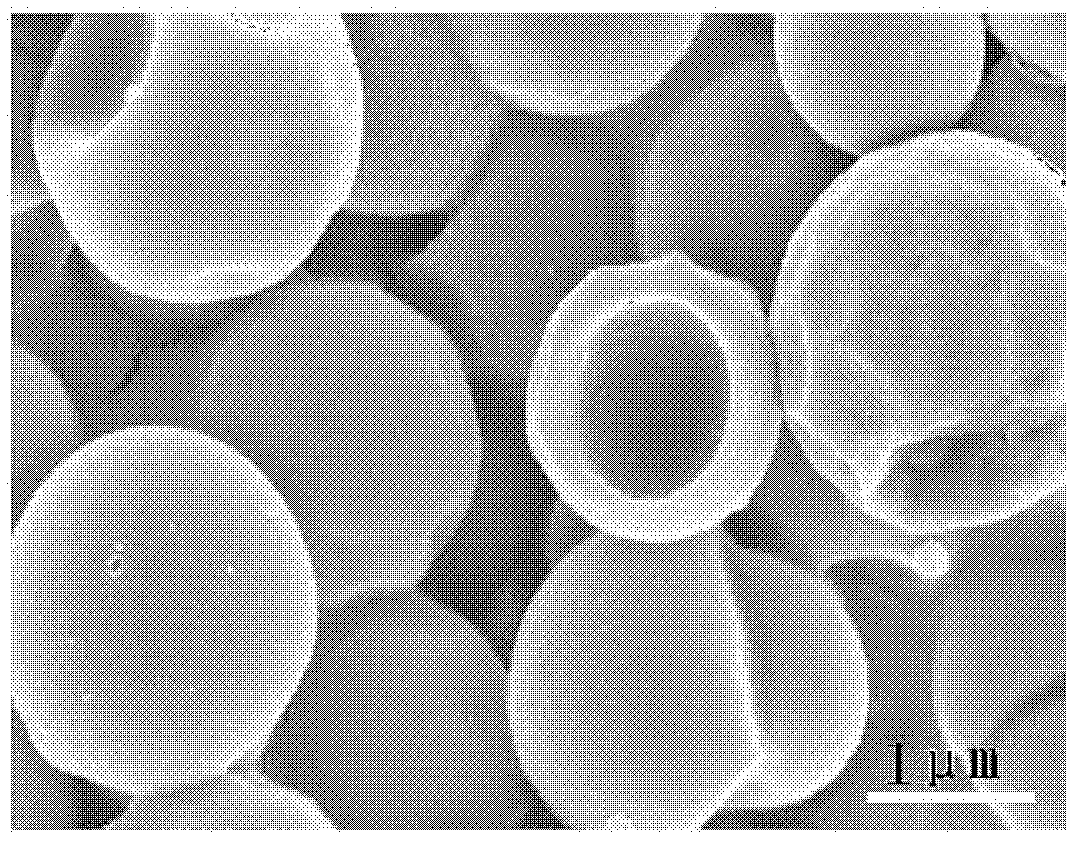

Image

Examples

specific Embodiment approach 1

[0017] Embodiment one: the preparation method of the nitrogen-containing graphitized hollow carbon microspheres of the present embodiment is carried out according to the following steps:

[0018] 1. Add melamine powder and formaldehyde solution with a mass concentration of 37% into deionized water, adjust the pH value to 5.5-9.0, then heat to 40-60°C and stir for 10min-30min, then heat up to 80-90°C and let stand Set aside for 10min to 30min to obtain a reaction liquid; wherein the molar ratio of melamine to formaldehyde is (1.5 to 6): 1;

[0019] 2. Transfer the reaction liquid obtained in step 1 to a stainless steel hydrothermal reaction kettle lined with polytetrafluoroethylene, seal it, and put it in an oven with a temperature of 120-200°C for 3-12 hours, take out the reaction kettle and let it cool naturally Cooling to room temperature, centrifuging the obtained product, washing the solid phase with deionized water and absolute ethanol in turn, and drying at room temperat...

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment differs from Embodiment 1 in that the mass percentage of nitrogen in the high-purity nitrogen described in step 3 is ≥99.99%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step one, melamine powder and a formaldehyde solution with a mass concentration of 37% are added to deionized water, heated to 45-55°C and stirred for 15min- After 25 minutes, the temperature was raised to 82-87°C and allowed to stand for 15-25 minutes to obtain a reaction solution. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com