High-brightness wear-resistant decorative sticky membrane paper and preparation method thereof

An adhesive film and high-gloss technology, which is applied in the field of building decoration materials, can solve the problems of difficult industrialization and high cost of nanomaterials, and achieve the effects of high hardness, high definition and reduced loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0036] Composition ratio and configuration method of urea-formaldehyde resin solution

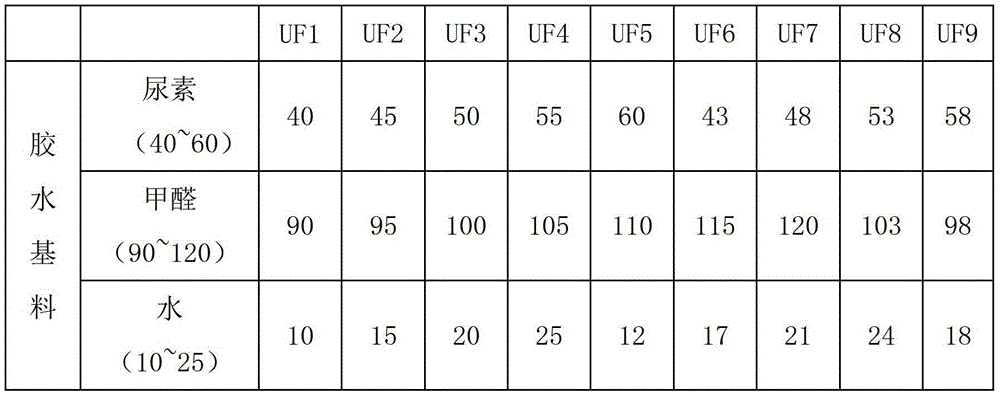

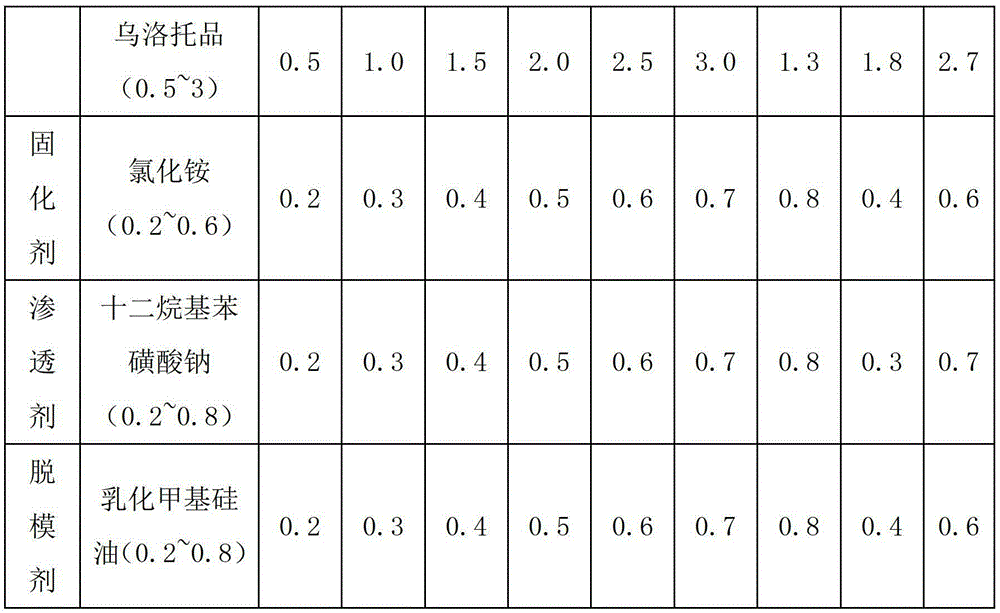

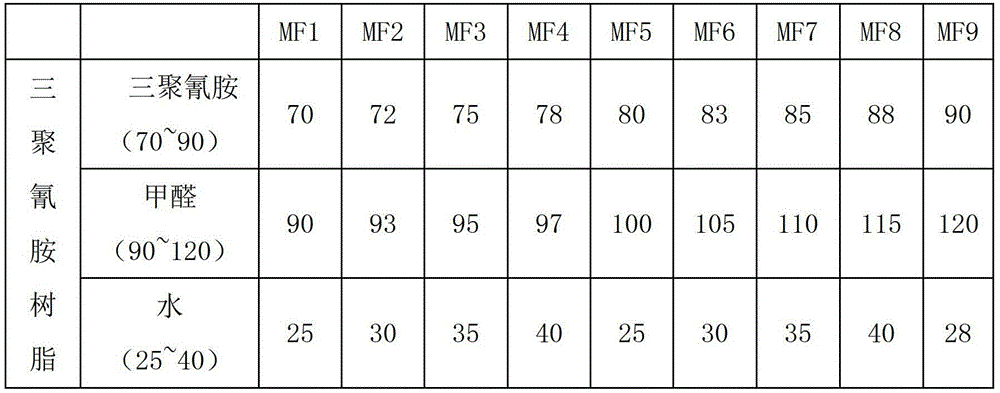

[0037] Table 1 The composition ratio table of urea-formaldehyde resin solution (UF) (all parts by weight)

[0038]

[0039]

[0040]Taking urea-formaldehyde resin solution UF6 as an example, accurately weigh each component according to the proportion of glue base material in urea-formaldehyde resin solution UF6 in the table, 43 parts of urea, 115 parts of formaldehyde, 17 parts of water, 3.0 parts of urotropine, water, Add the formaldehyde solution to the reaction kettle, adjust the pH to 8.0-8.5 with caustic soda, add two-thirds of urea, heat to 90-93°C for 20 minutes, add formic acid to adjust the pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com