Graphene-melamine foam aerogel and preparation method thereof

A melamine and graphene technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of small adsorption capacity and slow adsorption rate, achieve rapid adsorption and improve hydrophilic performance , the effect of enriching the pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh 40 mg of graphene oxide, dissolve in 20 mL of deionized water, and ultrasonically disperse for 3 h to form a uniform graphene oxide aqueous solution. Take 10mL of graphene oxide aqueous solution, mix it with 100mg of ascorbic acid, put it into the melamine foam purchased from Suzhou Xinkerui Company, put it in an oven at 80°C for 3h, and obtain the graphene-melamine foam hydrogel; After being replaced in deionized water for 24 hours, the graphene-melamine foam airgel was prepared by freeze-drying at -70°C for 24 hours.

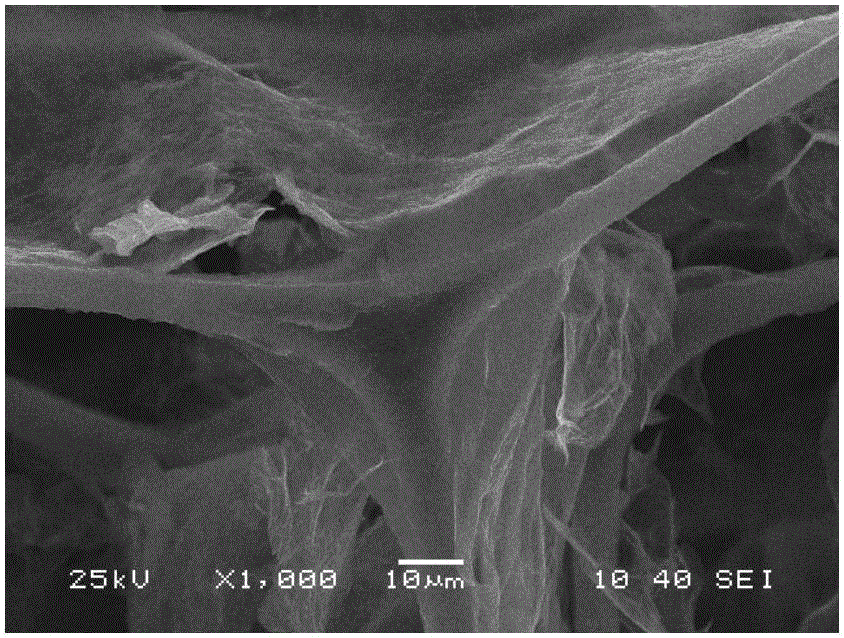

[0023] The airgel prepared in this example is a black block with a density of 11 mg / cm 3 , the specific surface area is 236m 2 / g. Its structure is as figure 1 As shown, the graphene sheet is covered on the melamine foam skeleton.

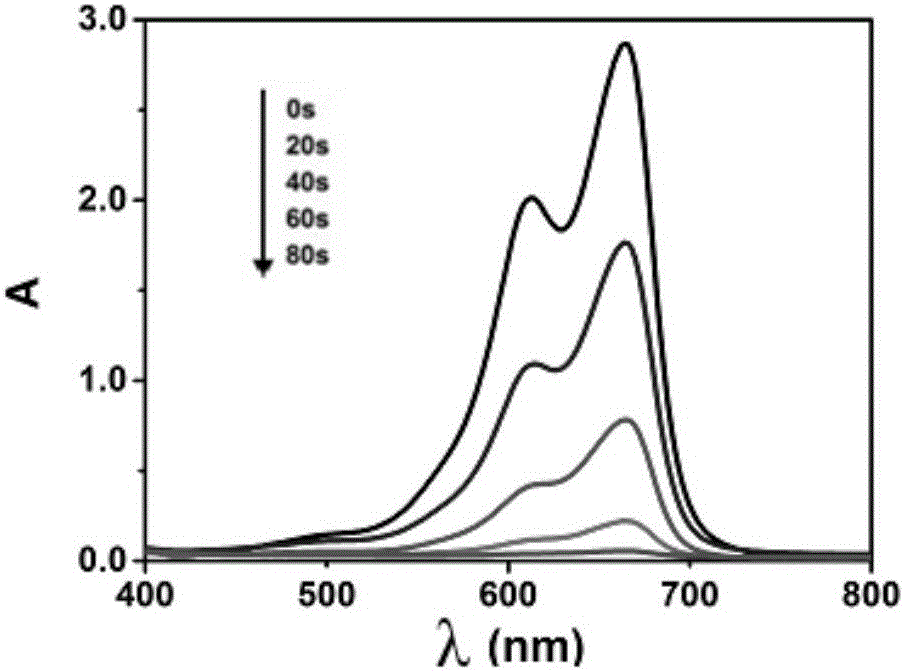

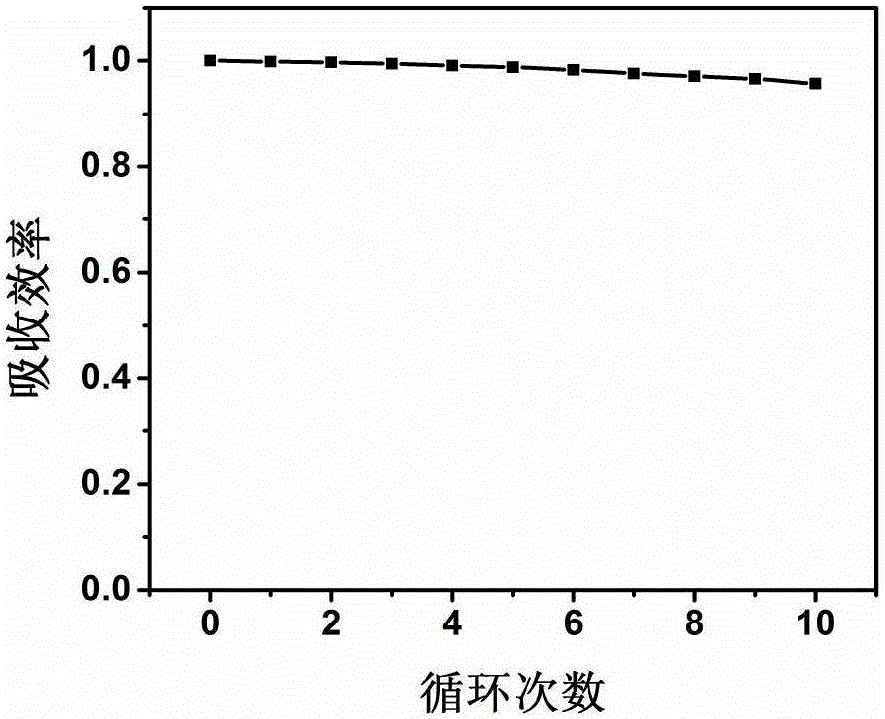

[0024] The rapid absorption effect test of the airgel prepared in this embodiment to the methylene blue solution is as follows: configure the methylene blue solution with a concentration of 10 mg / L, take 100 mL in ...

Embodiment 2

[0027] Weigh 20 mg of graphene oxide, dissolve in 20 mL of deionized water, and ultrasonically disperse for 1 h to form a graphene oxide aqueous solution. Take 16 mL of graphene oxide aqueous solution, add 160 mg of ascorbic acid and 4 mL of dopamine solution with a concentration of 2 mg / mL, mix evenly, put it into melamine foam, and place it in an oven at 95 °C for 12 hours to obtain graphene-melamine foam hydration glue. After the hydrogel was replaced in de-tert-butanol for 24 hours, it was freeze-dried at -70°C for 48 hours to prepare graphene-melamine foam airgel.

[0028] The airgel prepared in this example is a black block with a density of 14 mg / cm 3 , the specific surface area is 318m 2 / g. The maximum absorption of methylene blue is 282 mg / g, the maximum absorption of crystal violet is 319 mg / g, and the maximum absorption of orange G is 67 mg / g. The fast adsorption time for methylene blue is 70s.

Embodiment 3

[0030] Weigh 60 mg of graphene oxide, dissolve in 20 mL of deionized water, and ultrasonically disperse for 4 h to form a uniform graphene oxide aqueous solution. Take 18 mL of graphene oxide aqueous solution, add 2 mL of dopamine solution with a concentration of 2 mg / mL, mix well, put it into melamine foam, and place it in an oven at 95 °C for 20 h to obtain graphene-melamine foam hydrogel. After replacing the hydrogel with ethanol for 24 hours, it was freeze-dried at -70°C for 72 hours to prepare a graphene-melamine foam aerogel.

[0031] The airgel prepared in this example is a black block with a density of 9 mg / cm 3 , the specific surface area is 276m 2 / g. The maximum absorption of methylene blue is 241 mg / g, the maximum absorption of crystal violet is 276 mg / g, and the maximum absorption of orange G is 49 mg / g. The fast adsorption time for methylene blue is 88s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com