Preparation method of graphene modified super-hydrophobic adsorption material

An adsorption material, graphene technology, applied in separation methods, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of oil-water mixtures that cannot be selectively absorbed, limited application, complicated preparation process, etc., to overcome the price of reagents. Expensive, fast industrial production, reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

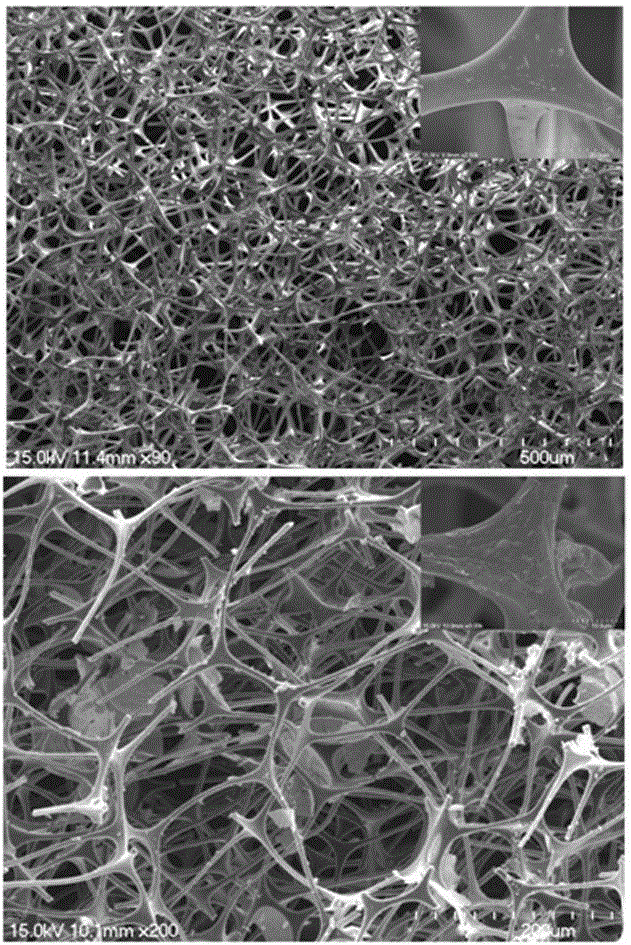

[0021] Example 1 Preparation of graphene-modified superhydrophobic adsorption material

[0022] (1) The preparation of melamine foam (MF), the specific steps are as follows:

[0023] Pour the formaldehyde solution with a concentration of 37% into a three-necked flask, heat it in a water bath at 35°C, and adjust the pH value of the solution to 9.0 with triethylamine, then add melamine in a molar ratio of formaldehyde:melamine=4.5:1, and heat up to 60°C to obtain a transparent solution, then add polyethylene glycol with a mass fraction of 10% of the solution, after it dissolves, lower the temperature to 45°C, then add the same amount of foaming agent (petroleum ether), and then stir at 1200rpm uniform, then add a curing agent, and finally foam at 200°C to obtain the final melamine foam.

[0024] (2) The preparation of graphene oxide (GO), the specific steps are as follows:

[0025] 3.0 g flake graphite was added into concentrated sulfuric acid (69 mL), and then magnetically st...

Embodiment 2

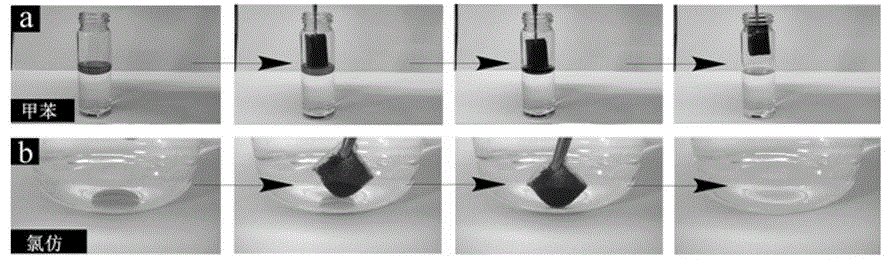

[0030] Example 2 The adsorption test of organic solvents, the specific steps are as follows:

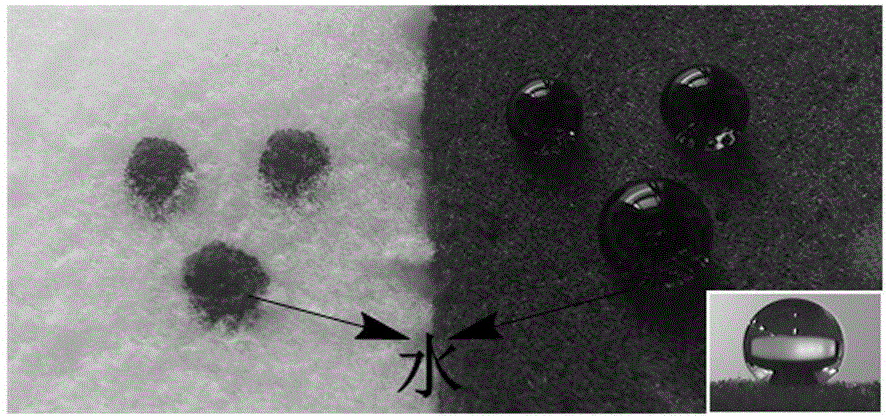

[0031] Take 2 mL of toluene and chloroform respectively into a beaker containing 20 mL of water, and then use GMF for adsorption test. attached image 3 They are the adsorption diagrams of toluene (a) and chloroform (b), respectively. It can be seen from the figure that both solvents can be completely adsorbed by GMF. This shows that the product prepared by the present invention has good oil absorption performance.

Embodiment 3

[0032] Embodiment three oil-water separation test, the specific steps are as follows:

[0033] Put GMF into the funnel, put it on the Erlenmeyer flask to prepare the oil-water separation device, and then pour 50 mL of oil-water mixture (volume ratio oil:water=1:1). attached Figure 4 It is a diagram of the oil-water separation process. During the whole process, the water is completely blocked on the GMF, while the oil flows into the lower cone, which shows that GMF has super hydrophobicity and lipophilicity, and shows a good separation effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com