Cleaning implement comprising melamine foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

examples

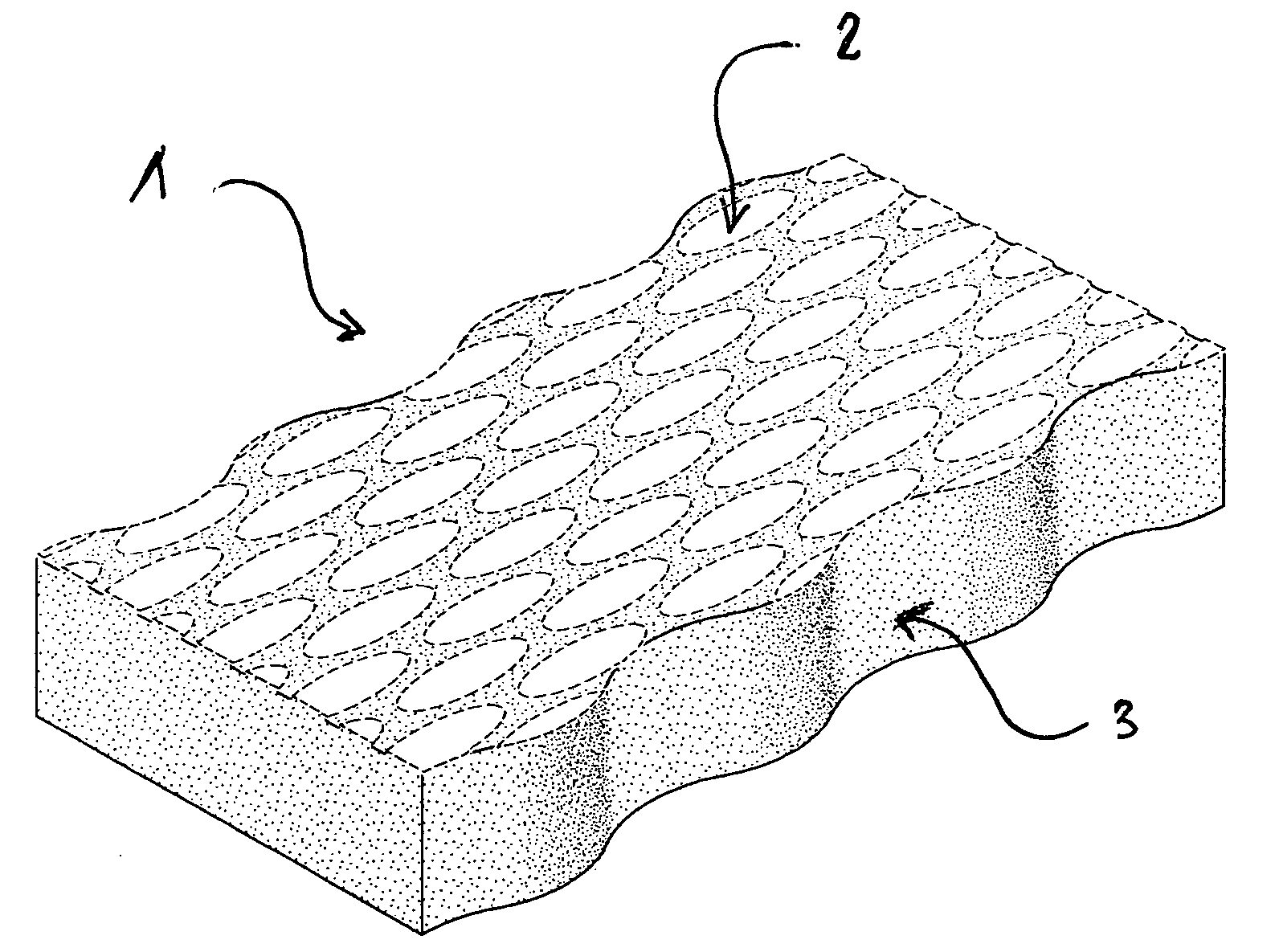

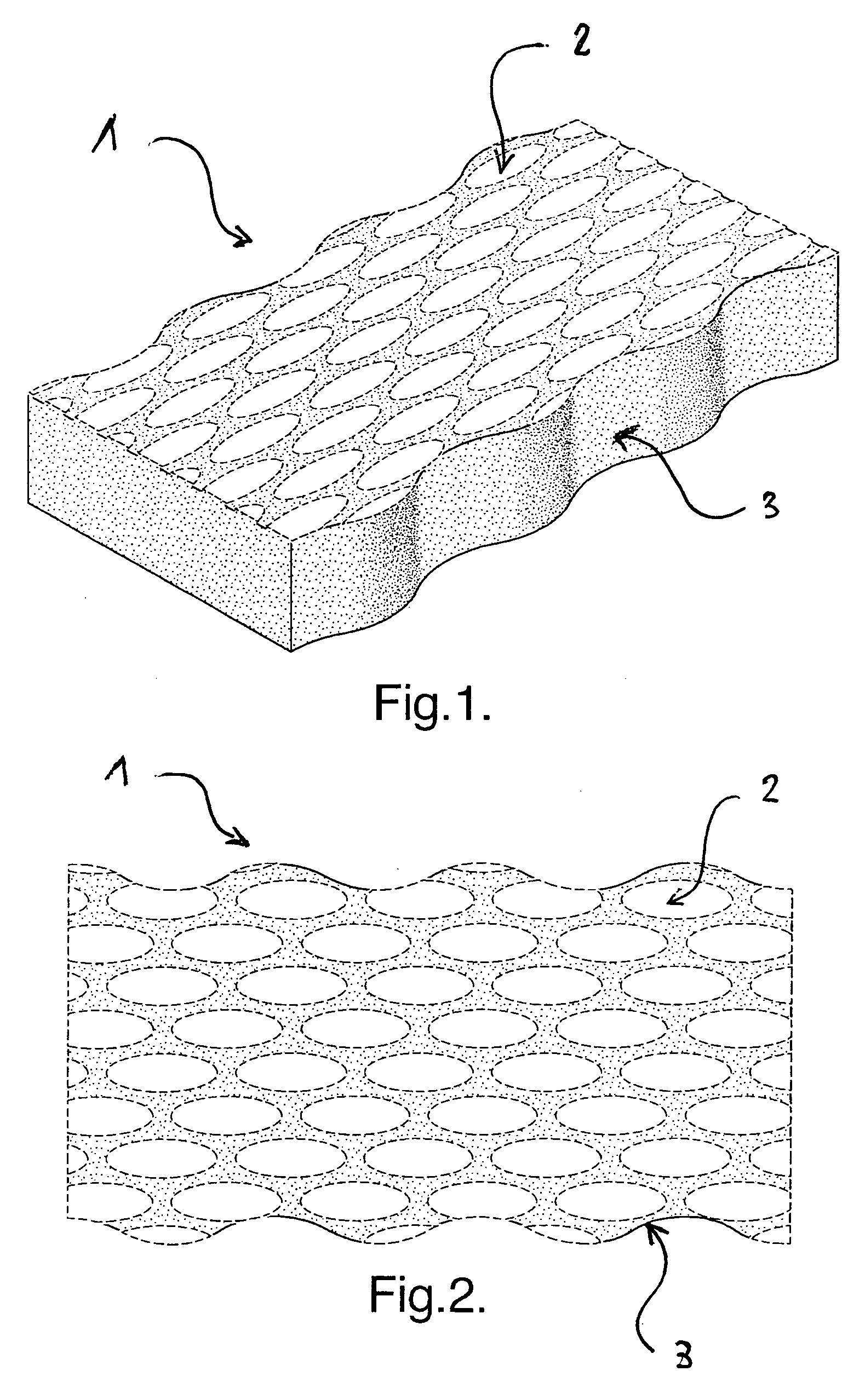

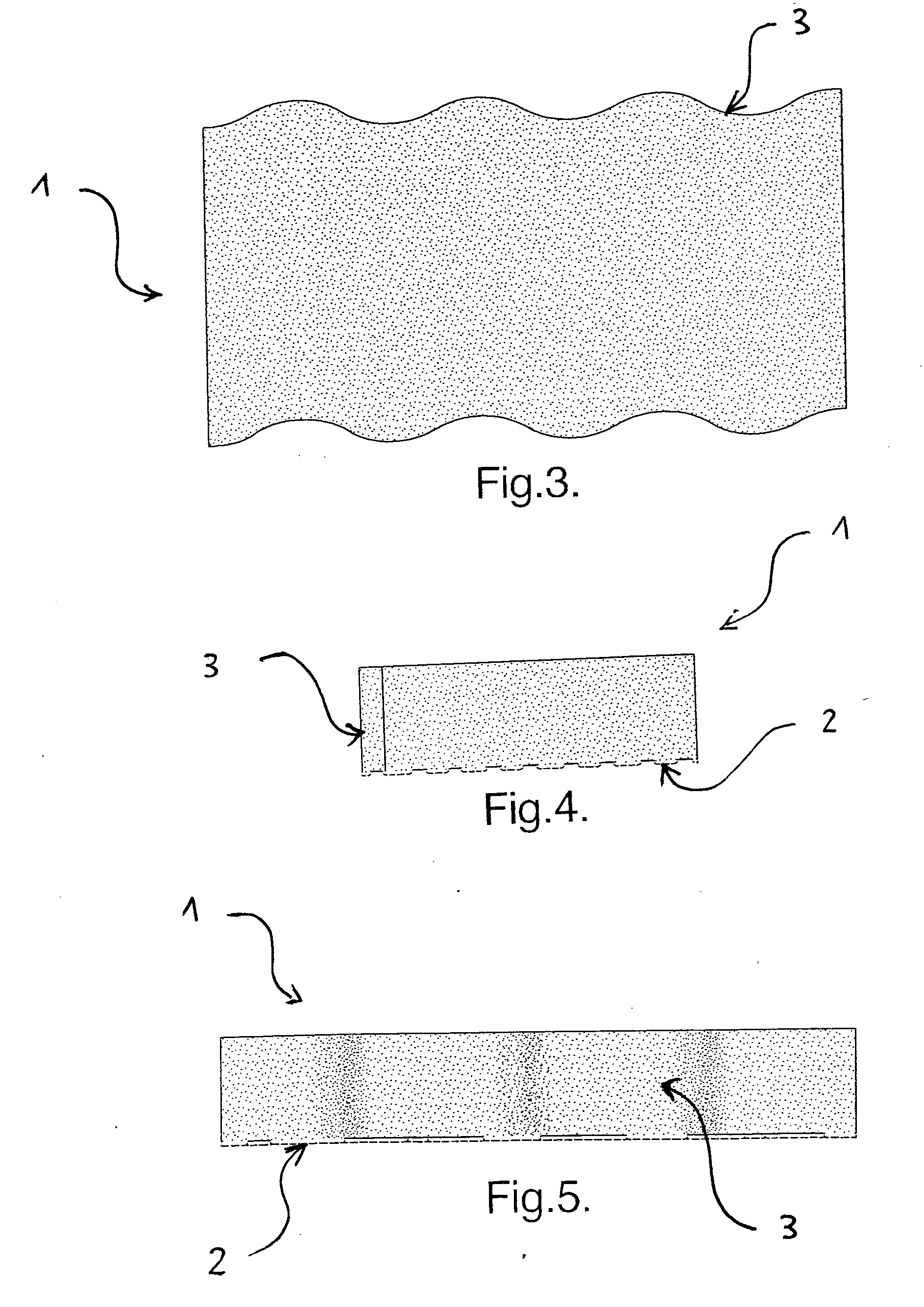

[0078] A cleaning implement 1 was made using a melamine-formaldehyde resin foam raw material commercially available under the trade name Basotect® from BASF. The melamine foam was submitted to heat-compression at about 273° C. for about 2.5 minutes between two heated metal plates of a commercially available plate press. The compression factor is about 2.0:1. The resulting cleaning implement 1 provides excellent cleaning performance benefit, in particular on tough soils, and very good thermal compression stability upon storage, even under stressed storing conditions. Furthermore, the cleaning implement 1 shows improved mechanical performances and therefore improved durability when compared to non-thermally compressed melamine foams currently available on the market.

Comparative Data

[0079] The following examples will further illustrate the present invention. The cleaning implements are made by heat-compressing melamine-formaldehyde resin foam raw material commercially available under...

experiment 1

formance.

[0080] A comparative greasy soap scum and neat kitchen dirt removal performance study is conducted according to the test method as previously described. The study involves a cleaning implement 1 according to the present invention (Cleaning implement 1) and a comparative / reference cleaning implement (Cleaning implement C). For both cleaning implements, the number of stroke cycles needed to perfectly clean the surface is measured. Performances on greasy soap scum and neat kitchen dirt removal is evaluated for the exemplified cleaning implement (Implement 1) with respect to the reference cleaning implement (Cleaning implement C). The corresponding performances are expressed in terms of Cleaning Index, which was calculated according to the following formula:

Cleaning index (CI)=(NS1 / NS2)×100

[0081] Where NS1=number of stroke cycles needed for the reference cleaning implement C. [0082] NS2=number of stroke cycles needed for the tested cleaning implement 1.

[0083] Results are prese...

experiment 2

the Heat-compression Under Stressed Storing Conditions.

[0085] Cleaning implements 1, A and B, are produced as indicated above and stored for about 120 hours at about 35° C. in a relative humidity of about 80%. The stability of the heat-compression under stressed conditions has been assessed using the test method as described herein above. The corresponding stabilities are expressed in terms of Rebound factor, which was calculated according to the formula as previously described. The lower the rebound factor, the lower decompression of the melamine foam after heat-compression is obtained, and therefore the better stability of the heat-compression under stressed conditions is achieved for the corresponding cleaning implements.

[0086] Results are presented in the table below.

CleaningCleaningCleaningimplement 1implement Aimplement BRebound factor8.93421.3(%)

[0087] The above results clearly show the improved stability upon moist storage of a cleaning implement 1 according to the presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com