High-temperature-resistance foam enhanced SiO2 aerogel thermal insulation material and preparation method thereof

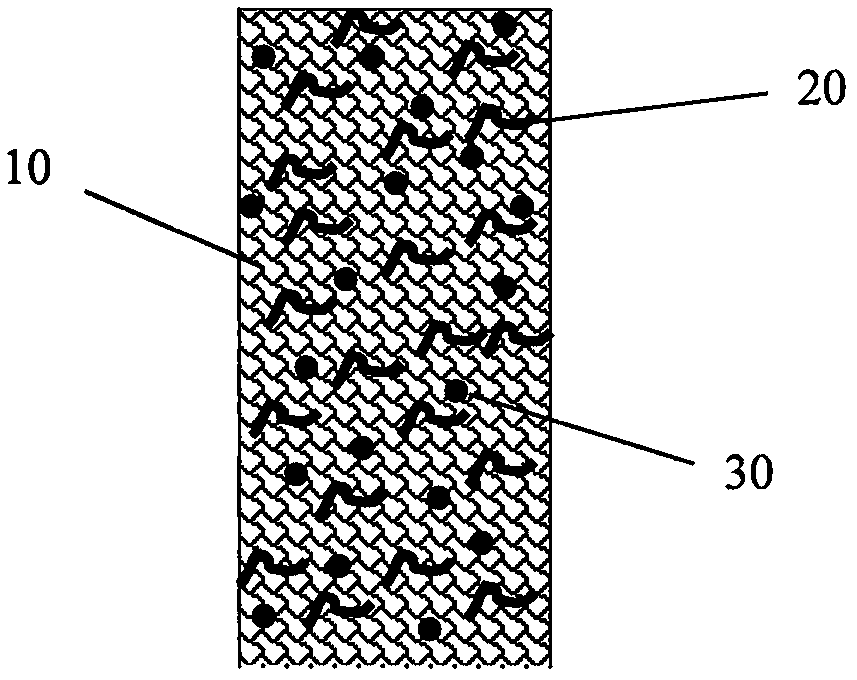

A thermal insulation material, aerogel technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems of loose structure, high thermal conductivity and poor compactness of SiC coating materials, achieve ultra-low overall density, and improve mechanical properties. performance, the effect of reducing the pore size of the foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Immerse the flexible carbon foam obtained by pyrolysis of melamine foam in absolute ethanol, clean it with ultrasonic vibration for 30 minutes, take it out and dry it in an oven at 100°C for later use;

[0022] (2) Nickel nitrate hexahydrate, dehydrated alcohol are prepared nickel nitrate solution according to the mol ratio of 1: 20;

[0023] (4) The carbon foam is immersed in the nickel nitrate solution for 10 hours;

[0024] (5) Dry after impregnation, put it into a vapor deposition furnace, and chemical vapor deposit silicon carbide nanowires, using trichloromethylsilane as the silicon carbide gas source, hydrogen as the carrier gas, and argon as the dilution gas, and the deposition temperature is 1100 ℃, the deposition time is 2h, and the silicon carbide-carbon composite foam material is formed;

[0025] (6) The silica sol with a silicon oxide mass fraction content of 15% is SiO 2 Airgel silicon source, mix and stir deionized water: absolute ethanol: silica so...

Embodiment 2

[0030] (1) Immerse the flexible carbon foam obtained by pyrolysis of melamine foam in absolute ethanol, clean it with ultrasonic vibration for 30 minutes, take it out and dry it in an oven at 100°C for later use;

[0031] (2) Nickel nitrate hexahydrate, dehydrated alcohol are prepared nickel nitrate solution according to the mol ratio of 1: 10;

[0032] (4) The carbon foam is immersed in the nickel nitrate solution for 10 hours;

[0033] (5) Dry after impregnation, put it into a vapor deposition furnace, and chemical vapor deposit silicon carbide nanowires, using trichloromethylsilane as the silicon carbide gas source, hydrogen as the carrier gas, and argon as the dilution gas, and the deposition temperature is 1100 ℃, the deposition time is 2h, and the silicon carbide-carbon composite foam material is formed;

[0034] (6) The silica sol with a silicon oxide mass fraction content of 15% is SiO 2 Airgel silicon source, mix and stir deionized water: absolute ethanol: silica so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com