Ultrathin buffer foam tape and production method thereof

A cushioning foam and ultra-thin technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve problems that affect product quality, easily generate air bubbles, time-consuming and labor-intensive, etc., to save manpower and material resources, save costs, eliminate The effect of Newton's rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

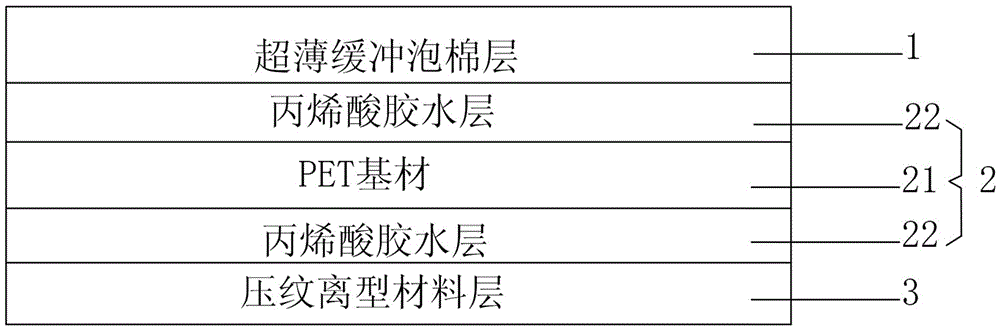

[0027] Such as figure 1 As shown, an embodiment of the ultra-thin buffer foam tape of the present invention, the ultra-thin buffer foam tape includes an ultra-thin buffer foam layer 1 , a PET double-sided tape 2 and an embossed release material layer 3 sequentially compounded. Wherein, the PET double-sided adhesive tape 2 is formed by a PET substrate 21 and an acrylic glue layer 22 coated on both surfaces thereof. The overall thickness of the ultra-thin buffer foam tape is 0.1-0.3mm, the thickness of the ultra-thin buffer foam layer 1 is 0.05-0.2mm, and the thickness of the PET double-sided adhesive tape is 5-20um.

[0028] The preparation method of the ultra-thin buffer foam tape is: preparing a PET double-sided tape and an ultra-thin buffer foam layer substrate, and sticking one side of the PET double-sided tape tightly on the ultra-thin buffer foam layer substrate; The other side of the PET double-sided tape is compounded with a layer of embossed release material. The ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com