Preparation method of zinc-based bimetallic-nitrogen-doped carbon material and application of zinc-based bimetallic-nitrogen-doped carbon material in electrode catalyst

A bimetallic, nitrogen-doped carbon technology, applied to battery electrodes, fuel cell half-cells, primary battery half-cells, circuits, etc., can solve the problems of large amount of organic solvents, high risk, high price, etc. , to achieve the effect of increased specific surface area, high product yield and good electrocatalytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Mix and dilute 10 g ferric chloride hexahydrate, 10 g zinc chloride, 20 ml 5 wt.% polyvinyl alcohol 1788 (~1 g) to 40 ml solution; cm 3 Soak the melamine foam in the above solution, take it out with tweezers, put it in a 60°C oven and dry it with air to obtain the precursor;

[0037] (2) Put the precursor into a tube furnace, use 50 ml / min of high-purity nitrogen as a protective gas, heat it to 900 °C at a heating rate of 5 °C / min, and keep it for 1 hour, and obtain a carbonized product after cooling;

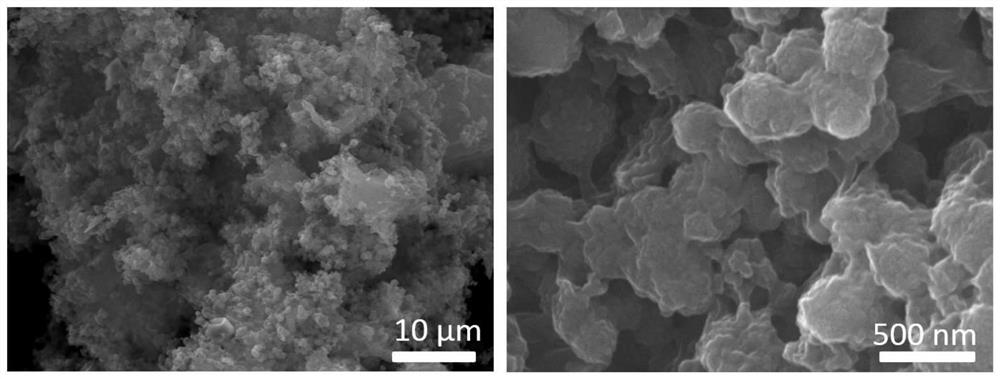

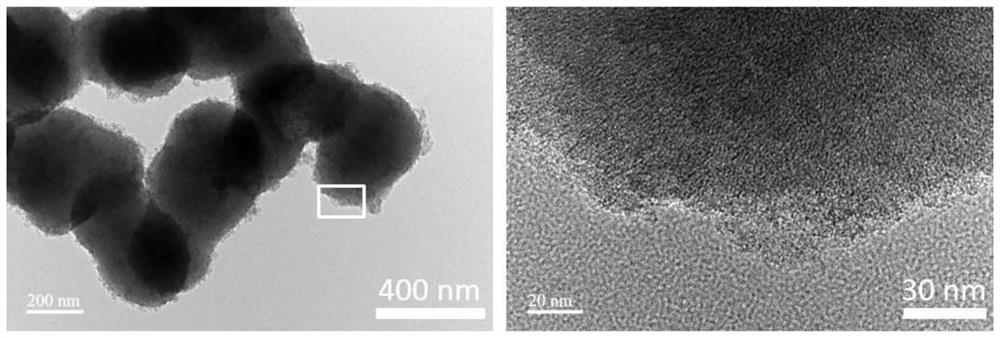

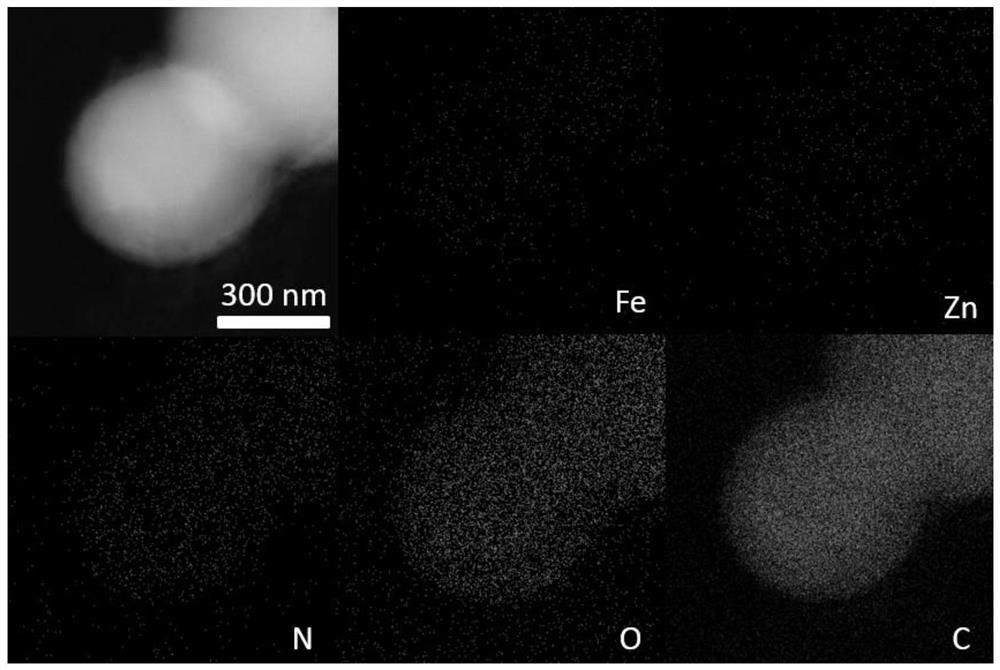

[0038] (3) Grind the carbonized product into a powder with a mortar, add 5 ml of 1 mol / L hydrochloric acid to sonicate for 0.5 hours, wash with water and ethanol for 3 times, put the centrifuged product in a 60°C oven and blow dry to obtain iron- Zinc-nitrogen doped chain-like porous carbon sphere material, named Fe-Zn-N-C;

[0039] (4) Ultrasonic dispersion of 5 mg of Fe-Zn-N-C and 5 mg of ruthenium dioxide in a mixed solvent of 1 ml of water and 1 ml of ethanol c...

Embodiment 2

[0051] (1) Mix and dilute 5 g ferric chloride hexahydrate, 5 g zinc chloride, 20 ml 5 wt.% polyvinyl alcohol 1788 (~1 g) to 40 ml solution; cm 3 Soak the melamine foam in the above solution, take it out with tweezers, put it in a 60°C oven and dry it with air to obtain the precursor;

[0052] (2) Put the precursor into a tube furnace, use 50 ml / min of high-purity nitrogen as the protective gas, heat it up to 800 °C at a heating rate of 5 °C / min, and keep it for 2 hours, and obtain a carbonized product after cooling;

[0053] (3) Grind the carbonized product into powder with a mortar, add 5 ml of 1 mol / L nitric acid to sonicate for 0.5 hours, wash with water and ethanol for 3 times, put the centrifuged product in a 60°C oven and dry it to obtain iron- Zinc-nitrogen doped chain-like porous carbon sphere material, named Fe-Zn-N-C2;

[0054] (4) Ultrasonic dispersion of 5 mg of Fe-Zn-N-C2 and 5 mg of ruthenium dioxide in a mixed solvent of 1 ml of water and 1 ml of ethanol conta...

Embodiment 3

[0058] (1) Mix and dilute 15 g ferric chloride hexahydrate, 15 g zinc chloride, 20 ml 5 wt.% polyvinyl alcohol 1788 (~1 g) to 40 ml solution; cm 3 Soak the melamine foam in the above solution, take it out with tweezers, put it in a 60°C oven and dry it with air to obtain the precursor;

[0059] (2) Put the precursor into a tube furnace, use 50 ml / min of high-purity argon as a protective gas, heat it to 1000 °C at a heating rate of 10 °C / min, and keep it for 1 hour, and obtain a carbonized product after cooling ;

[0060] (3) Grind the carbonized product into a powder with a mortar, add 5 ml of 1 mol / L sulfuric acid to sonicate for 0.5 hours, wash with water and ethanol for 3 times, put the centrifuged product in a 60°C oven and blow dry to obtain iron- Zinc-nitrogen doped chain-like porous carbon sphere material, named Fe-Zn-N-C3;

[0061] (4) Ultrasonic dispersion of 5 mg of Fe-Zn-N-C3 and 5 mg of ruthenium dioxide in a mixed solvent of 1 ml of water and 1 ml of ethanol co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Limiting current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com