Polyurethane elastomer and sole made from same

A polyurethane elastomer, polyurethane technology, used in polyurea/polyurethane coatings, shoe soles, footwear, etc., can solve the problems of insufficient strength and low density, and achieve low density, excellent bending resistance and aging resistance, high Effects of elasticity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

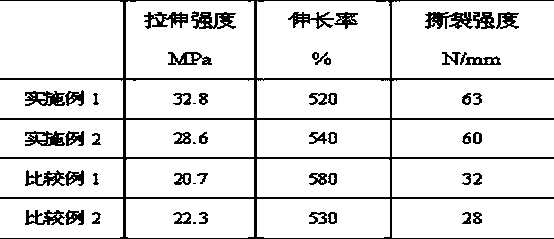

[0017] The polyurethane elastomer described in this embodiment consists of 20 parts by weight of carbodiimide modified MDI, 8 parts by weight of polyester polyol P-2013 (Japan Kuraray Company), 6 parts by weight of polymer polyol , 6 parts by weight of 1,4-butanediol, 2.0 parts by weight of polyethylene-vinyl acetate copolymer (the content of polyethylene in the copolymer is 35wt%), 1.5 parts by weight of diethylamino ethyl methacrylate The composition of ester, 0.20 parts by weight of triethylenediamine, 0.40 parts by weight of water, and 0.25 parts by weight of foam stabilizer DC-193 is mixed uniformly at 100 ° C, and then injected into the preheating temperature of 115 ° C In the predetermined shape of the mold, react for 25 minutes, demould and then aged at 110°C for 12 hours to obtain the polyurethane elastomer.

Embodiment 2

[0019] The polyurethane elastomer described in this embodiment consists of 22 parts by weight of carbodiimide modified MDI, 10 parts by weight of polyester polyol P-2013 (Japan Kuraray Company), 5 parts by weight of polymer polyol , 5 parts by weight of 1,4-butanediol, 1.8 parts by weight of polyethylene-vinyl acetate copolymer (the content of polyethylene in the copolymer is 35wt%), 1.5 parts by weight of diethylamino ethyl methacrylate The composition of ester, 0.20 parts by weight of triethylenediamine, 0.40 parts by weight of water, and 0.25 parts by weight of foam stabilizer DC-193 is mixed uniformly at 100 ° C, and then injected into the preheating temperature of 115 ° C In the predetermined shape of the mold, react for 25 minutes, demould and then aged at 110°C for 12 hours to obtain the polyurethane elastomer.

Embodiment 3

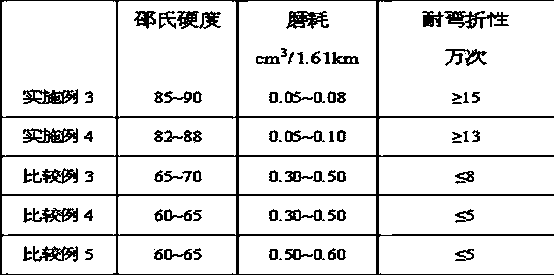

[0028]This embodiment relates to a shoe sole, the shoe sole is mainly formed by the polyurethane elastomer of Example 1, and the surface treatment liquid is coated on the surface of the polyurethane elastomer, and then cured at 100 ° C for 2 to 3 minutes, and then Re-cure at 120°C for 1 minute; a polyurethane wear-resistant layer with a thickness of about 0.5 mm is formed. The surface treatment solution is a treatment solution composed of a first polyurethane component and a second polyurethane component; and the mass ratio of the first polyurethane component to the second polyurethane component is 2:1. The first polyurethane component consists of 10-12 parts by weight of TDI-80, 3-4 parts by weight of polytrimethylene ether glycol (Cerenol H series from DuPont, USA), 2.0-2.5 parts by weight of 1,4 -Butanediol, 1.8~2.0 parts by weight of HTBN, 0.1~0.2 parts by weight of dibutyltin dilaurate mixed, 30~32 parts by weight of deionized water and 0.8~1.2 parts by weight of sodium l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com