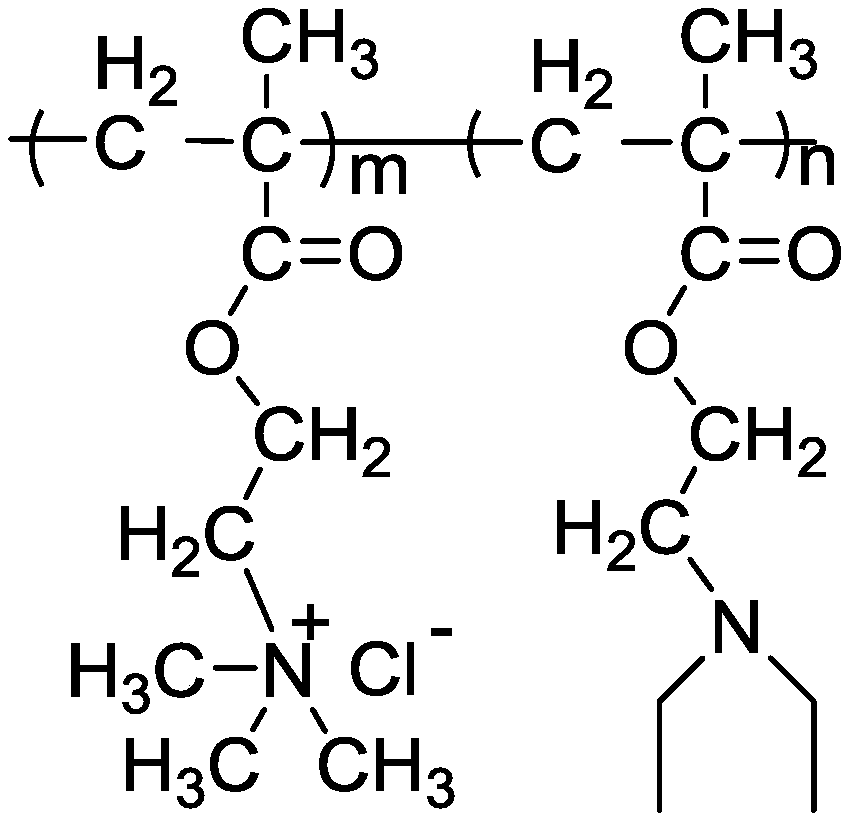

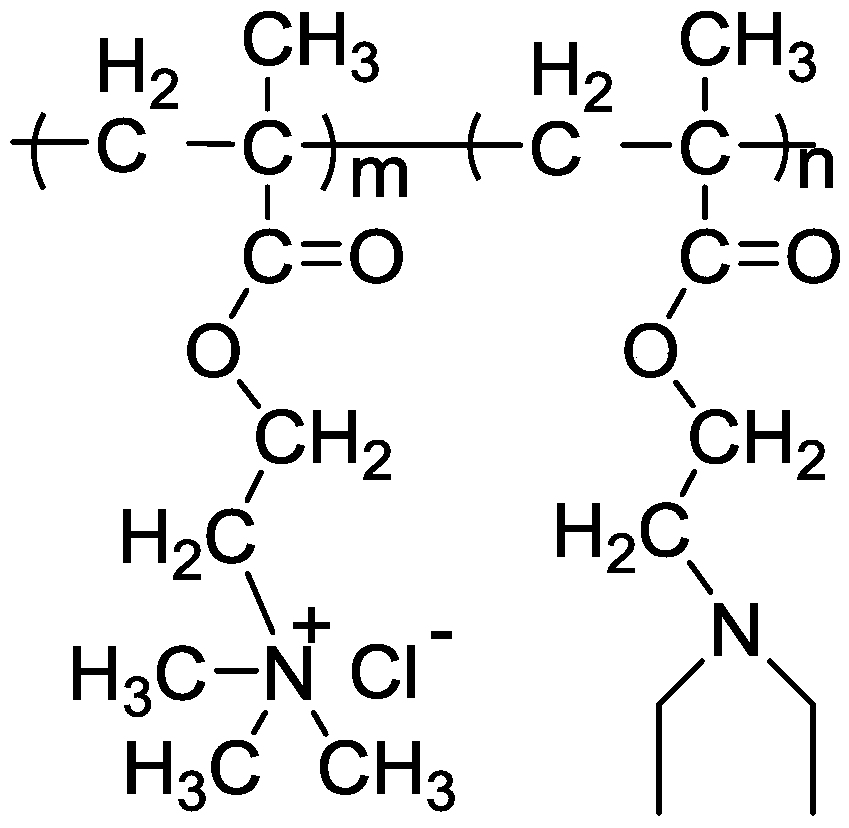

PH-responsive heavy oil emulsifier and preparation method thereof

An emulsifier, type heavy oil technology, used in mechanical equipment, piping systems, gas/liquid distribution and storage, etc. problems such as low, to achieve good surface activity and emulsification and viscosity reduction performance, low cost, and solve the effect of difficult handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 18g of diethylaminoethyl methacrylate and 2g of methacryloyloxyethyltrimethylammonium chloride into a 250mL flask to form an aqueous solution with a total mass concentration of monomers of 20%. The total weight of 0.5% of the initiator was reacted at 70° C. for 8 hours to obtain a thick oil emulsifier.

[0019] Take 50 g of heavy oil (viscosity at 50° C. of 30000 mPa.s), dissolve 2 g of the heavy oil viscosity reducer in Example 1 in 50 mL of distilled water, then add the heavy oil into the emulsifier under stirring, and measure its viscosity at 50° C. It is 241mPa.s, the viscosity reduction rate is 99.26%, and the water precipitation rate is 10% after 2 hours. However, the pH of the emulsion was adjusted to 5-6 with HCl, and the emulsion broke and separated rapidly, and the water separation rate reached more than 80% within 0.5 hours.

Embodiment 2

[0021] Add 16g of diethylaminoethyl methacrylate and 4g of methacryloyloxyethyltrimethylammonium chloride into a 250mL flask to prepare an aqueous solution with a total mass concentration of monomers of 20%. 0.5% of the total mass of the initiator was reacted at 70° C. for 8 hours to obtain a thick oil emulsifier.

[0022] Take 50 g of heavy oil (viscosity at 50° C. of 30000 mPa.s), dissolve 3 g of the heavy oil viscosity reducer in Example 1 in 50 mL of distilled water, then add the heavy oil to the emulsifier under stirring, and measure its viscosity at 50° C. It is 113mPa.s, the viscosity reduction rate is 99.65%, and the water precipitation rate is 11% after 2 hours. However, the pH of the emulsion was adjusted to 5-6 with HCl, and the emulsion broke and separated rapidly, and the water separation rate reached more than 80% within 0.5 hours.

Embodiment 3

[0024] Add 14g of diethylaminoethyl methacrylate and 6g of methacryloyloxyethyltrimethylammonium chloride into a 250mL flask to form an aqueous solution with a total mass concentration of monomers of 20%. 0.5% of the total mass of the initiator was reacted at 70° C. for 8 hours to obtain a thick oil emulsifier.

[0025] Take 50 g of heavy oil (viscosity at 50° C. of 30,000 mPa.s), dissolve 4 g of the thick oil viscosity reducer in Example 1 in 50 mL of distilled water, then add the heavy oil to the emulsifier under stirring, and measure its viscosity at 50° C. It is 74mPa·s, the viscosity reduction rate is 99.77%, and the water precipitation rate is 3% after 2 hours. However, the pH of the emulsion was adjusted to 5-6 with HCl, and the emulsion broke and separated rapidly, and the water separation rate reached more than 80% within 0.5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com