Polymer, preparation method and poly-N-isopropylacrylamide europium complex micelle

A technology of isopropylacrylamide and polymethacrylic acid, applied in the field of europium complexes, can solve the problems of unstable micelles, easily affected by pH., solvent, temperature and ionic strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a kind of preparation method of polymer, this method comprises:

[0043] Step 1: Reaction of α-haloacyl halide and polyethylene glycol monomethyl ether to obtain ATRP initiator mPEG 23 -X, where X is a halogen;

[0044] Step 2: In the Cu(I)X organic ligand catalytic system, the ATRP initiator mPEG obtained in Step 1 23 -X reacts with N-isopropylacrylamide to obtain polyethylene glycol monomethyl ether-polyN-isopropylacrylamide mPEG 23 -PNIPAM.

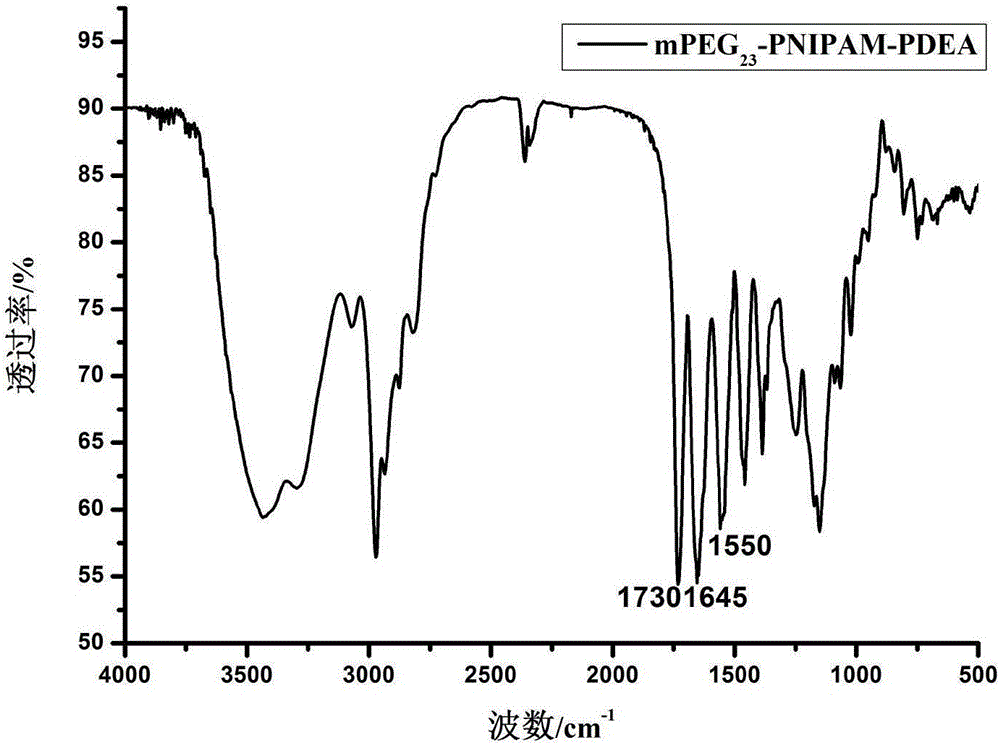

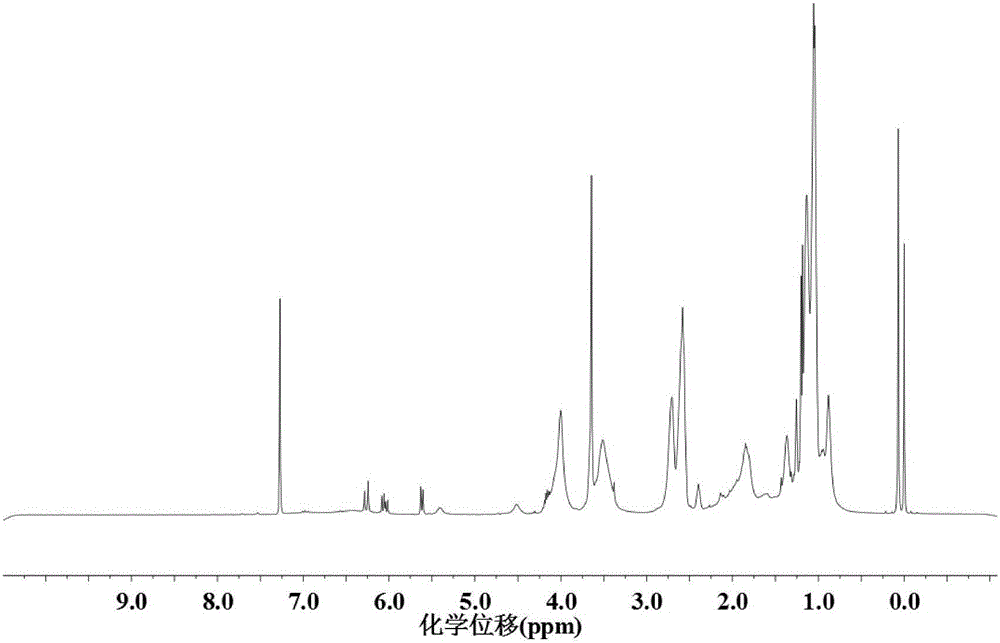

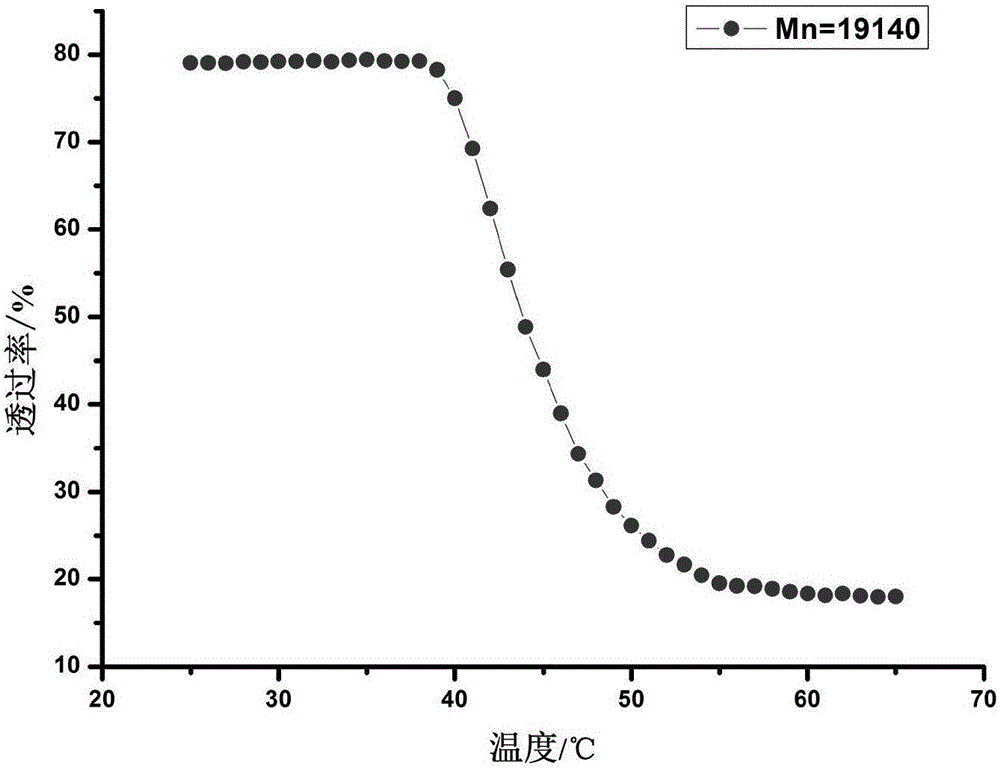

[0045] Step 3: In the Cu(I)X organic ligand catalytic system, the polyethylene glycol monomethyl ether-poly N-isopropylacrylamide and N,N-diethylaminoethyl methacrylate obtained in Step 2 Reaction to obtain the polymer polyethylene glycol monomethyl ether-poly N-isopropylacrylamide-polymethacrylate N,N-diethylaminoethyl ester mPEG 23 -PNIPAM-PDEA.

[0046] According to the present invention, add polyethylene glycol monomethyl ether (mPEG) in reaction vessel earlier 23 -OH) and solvent, s...

Embodiment 1

[0056] 250mgPEG 23 -OH and 30ml anhydrous CH 2 Cl 2 Add it to a 250ml single-necked flat-bottomed flask, then add 25μl triethylamine, place it in an ice-water bath, and add 5ml of anhydrous dichloromethane dissolved with 25μl of 2-bromoisobutyryl bromide in a constant pressure dropping funnel , drop for half an hour, seal well, stir and react at room temperature for 24 hours, after the reaction in dichloromethane, directly wash three times with NaCl aqueous solution, dry the extract with anhydrous magnesium sulfate, filter to remove magnesium sulfate, and spin The dichloromethane was removed by the evaporator, and the product was precipitated in excess glacial ether, filtered to obtain a white precipitate, and vacuum-dried at room temperature for 24 hours to obtain the macromolecular initiator mPEG 23 -Br;

[0057] Add 110mg initiator mPEG to one side of tube W 23 -Br, 904mgNIPAM and 8ml solvent, the solvent is DMF and water (V / V=1:1), add 10mgCuCl and 1ml deionized water ...

Embodiment 2

[0061] 2.5gPEG 23 -OH and 30ml anhydrous CH 2 Cl 2 Add it to a 250ml single-necked flat-bottomed flask, then add 250μl triethylamine, place it in an ice-water bath, and add 5ml of anhydrous dichloromethane dissolved in 250μl of 2-bromoisobutyryl bromide in a constant pressure dropping funnel , drop for half an hour, seal well, stir and react at room temperature for 48 hours, after the reaction in dichloromethane, directly wash three times with NaCl aqueous solution, dry the extract with anhydrous magnesium sulfate, filter to remove magnesium sulfate, and spin The dichloromethane was removed by the evaporator, and the product was precipitated in excess glacial ether, filtered to obtain a white precipitate, and vacuum-dried at room temperature for 48 hours to obtain the macromolecular initiator mPEG 23 -B;

[0062] Add 110mg initiator mPEG to one side of tube W 23 -Br, 1.13g NIPAM and 10ml solvent, the solvent is DMF and water (V / V=1:2), add 10mgCuCl and 1ml deionized water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com