Method for extracting valuable metal from waste hydrogenation catalyst

A technology of spent catalysts and catalysts, applied in the direction of improving process efficiency, etc., can solve problems such as production environmental pollution and difficult acid treatment, and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with accompanying drawing:

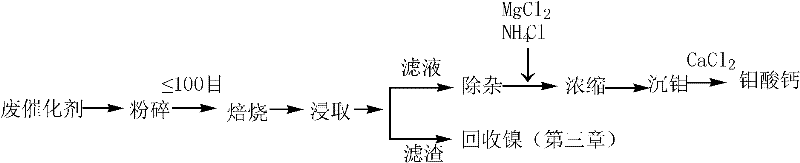

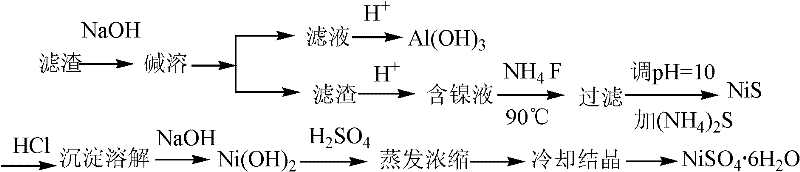

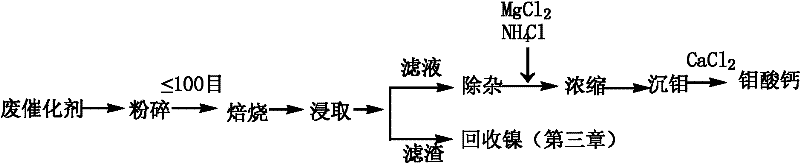

[0067] Such as figure 1 , figure 2 , the method for extracting useful metals from spent hydrogenation catalysts of the present invention roasts spent catalysts at high temperature, burns off organic matter, sulfur and carbon, then leaches the catalyst through desulfurization and decarburization, and removes Mo, V, There is still a small amount of Al converted into water-soluble, and other metal oxides remain in the solid slag, and then they are processed separately. For the water-soluble part, first remove the impurity ions in the solution such as AlO2-, SiO32-, etc. by controlling the temperature and adjusting the pH, and then use ammonium salt to precipitate V in the filtrate in the form of NH4VO3 and filter. Then adjust the pH and add calcium chloride to precipitate molybdenum as calcium molybdate. For the solid slag part, which contains NiO, Al2O3, etc., first disso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com