Fe-doped two-phase nickel sulfide nano array material, as well as preparation method and application thereof

A nano-array and nickel sulfide technology, which is applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of low conductivity of hydroxides, reduce energy use efficiency, etc., and increase the specific surface area , low cost, excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

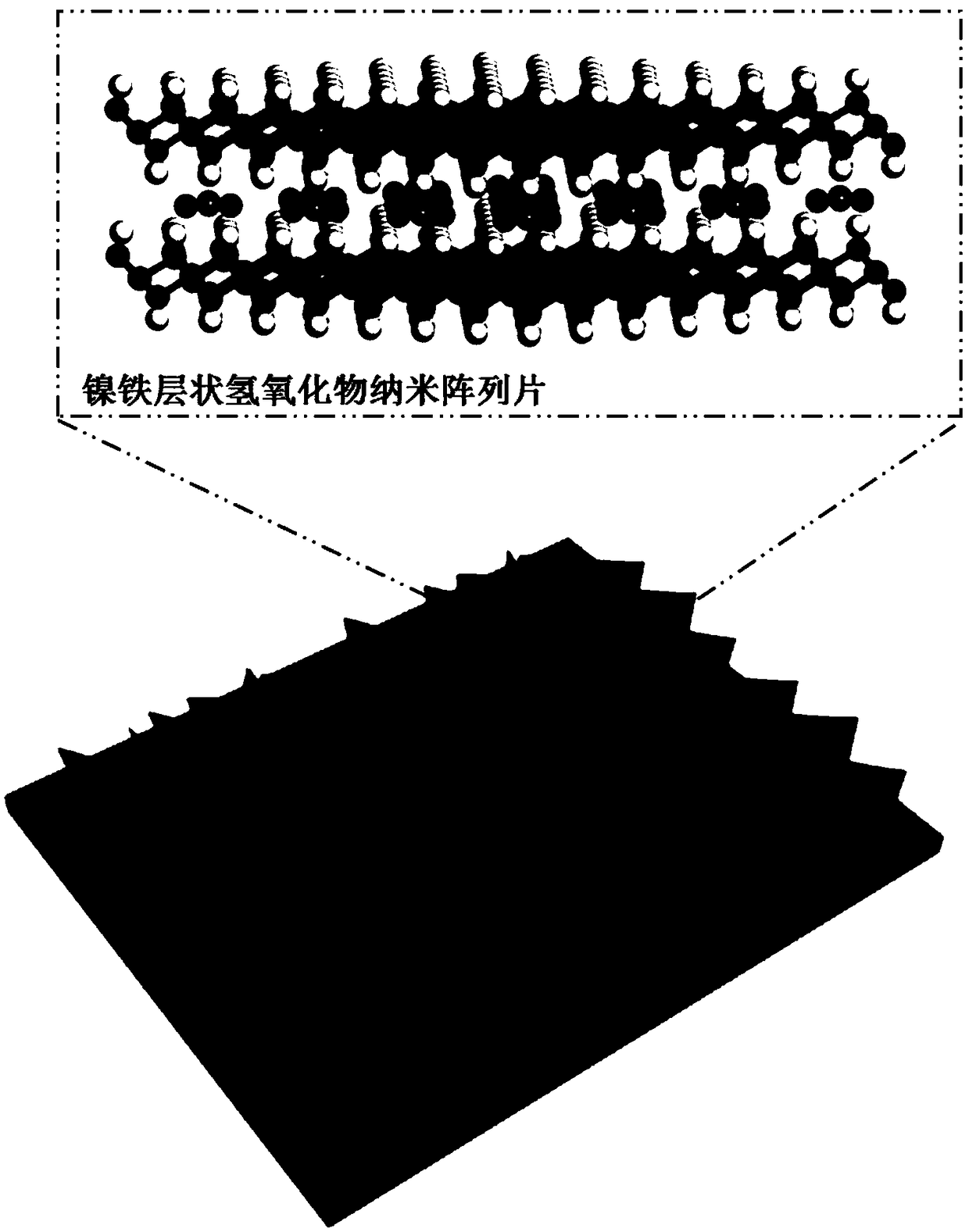

[0036] (1) In the first reaction kettle, it is an aqueous solution containing 0.2 mol / liter of nickel nitrate, 0.1 mol / liter of iron nitrate, and 1.5 mol / liter of urea. Put the acid-treated nickel foam base material into the first reactor, then seal the reactor, raise the temperature to 100° C. and keep it under autogenous pressure for 12 hours to perform the first solvothermal reaction. After the reaction, nickel-iron layered hydroxide nano-arrays grow on the surface of the vertical nickel foam substrate. The nickel-iron layered hydroxide nano-array material is taken out, washed and dried.

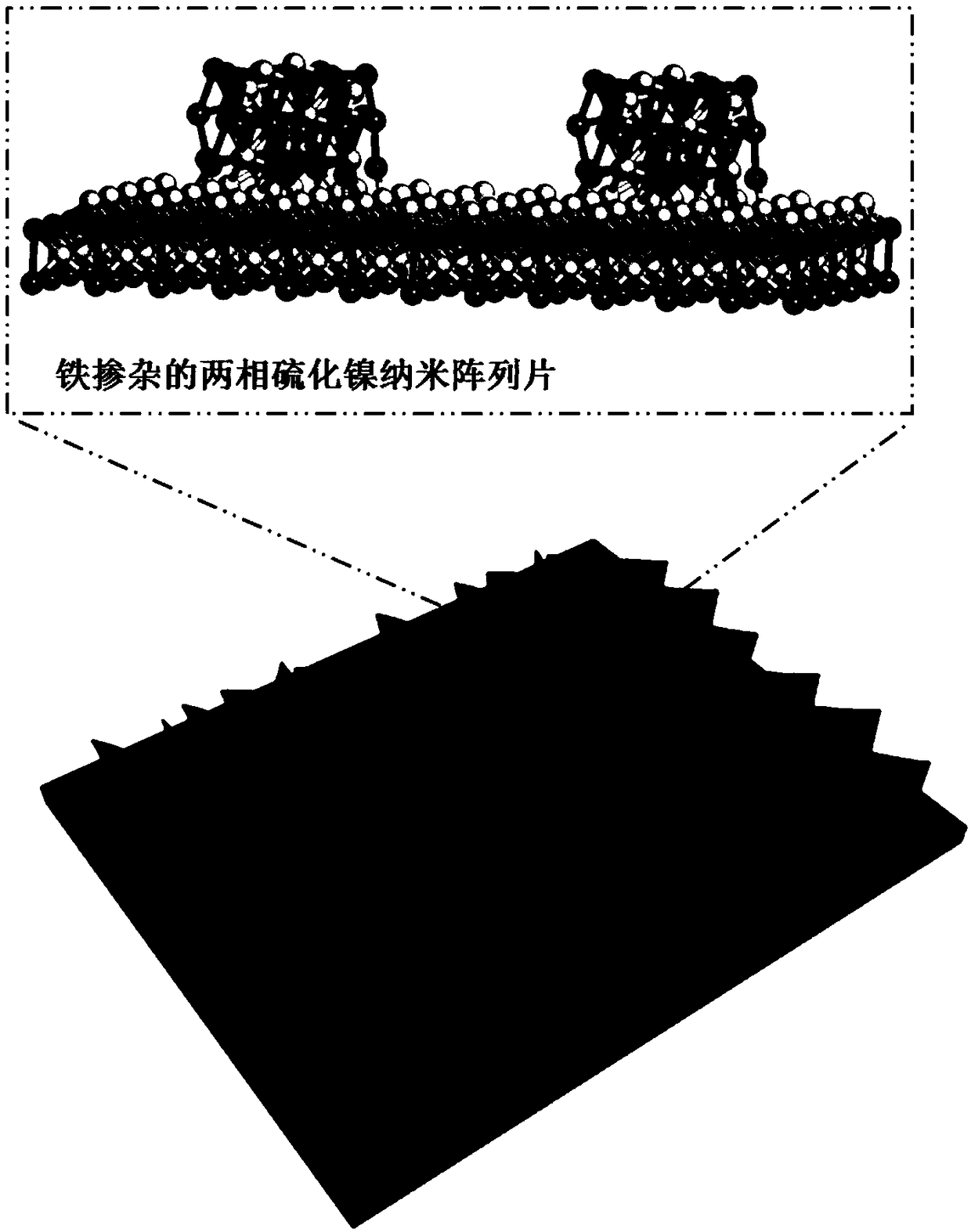

[0037] (2) Put the nickel-iron layered hydroxide nanoarray material obtained in step (1) into a second reaction kettle, which contains 0.625 mol / liter of sulfur in carbon disulfide solution. Seal the reaction kettle, raise the temperature to 120° C. and keep it under autogenous pressure for 24 hours to carry out the second solvothermal reaction, so that each nickel-iron layered hydroxide...

Embodiment 2

[0043] Referring to the method in Example 1, the concentration of elemental sulfur in carbon disulfide was changed to 0.5 mol / L, and the conditions of the second solvothermal reaction were changed to: the temperature was 140° C., and the reaction time was 24 hours.

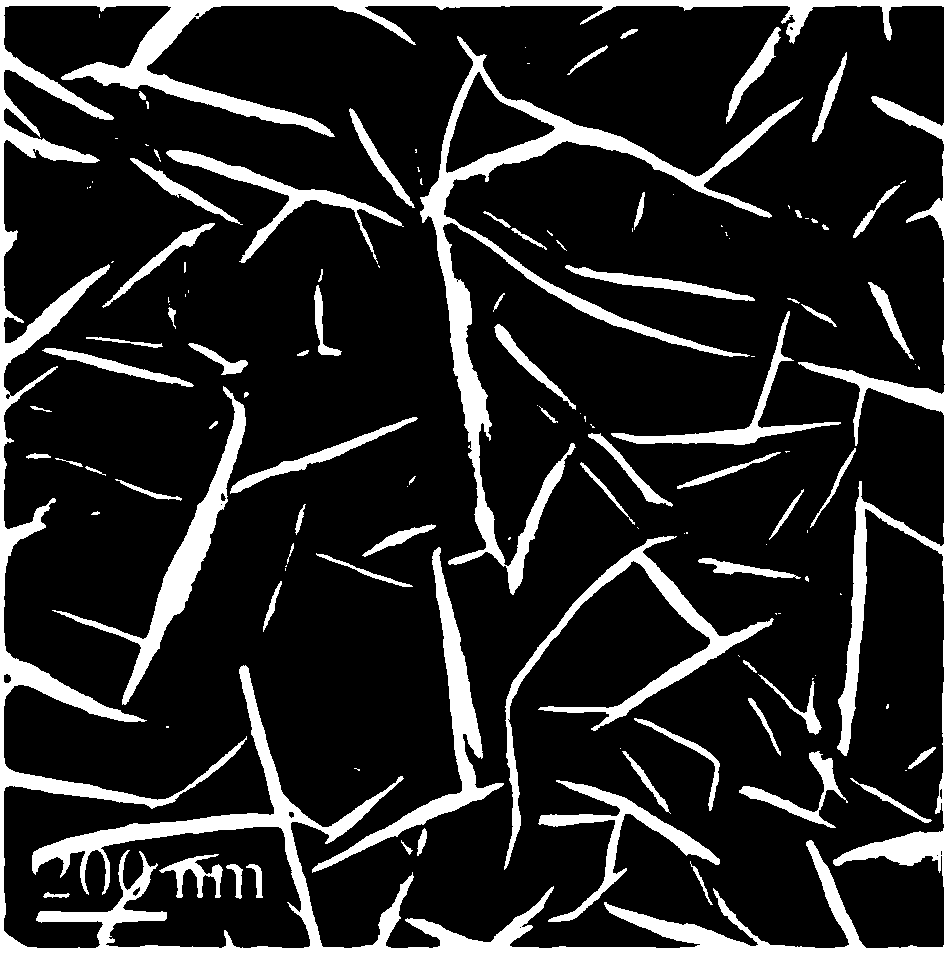

[0044] The scanning electron microscope of the obtained iron-doped two-phase nickel sulfide nanoarray material is shown in the appendix Figure 8 .

Embodiment 3

[0046] Referring to the method in Example 1, the concentration of elemental sulfur in carbon disulfide was changed to 0.625 mol / L, and the conditions of the second solvothermal reaction were changed to: the temperature was 160° C., and the reaction time was 8 hours.

[0047] The scanning electron microscope of the obtained iron-doped two-phase nickel sulfide nanoarray material is shown in the appendix Figure 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com