Nickel sulfide, copper tailings comprehensive recovery technology

A technology of copper tailings and nickel sulfide, which is applied to the improvement of process efficiency, chemical instruments and methods, solid separation, etc., to achieve the effects of high production efficiency, low cost and advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below using the drawings and examples.

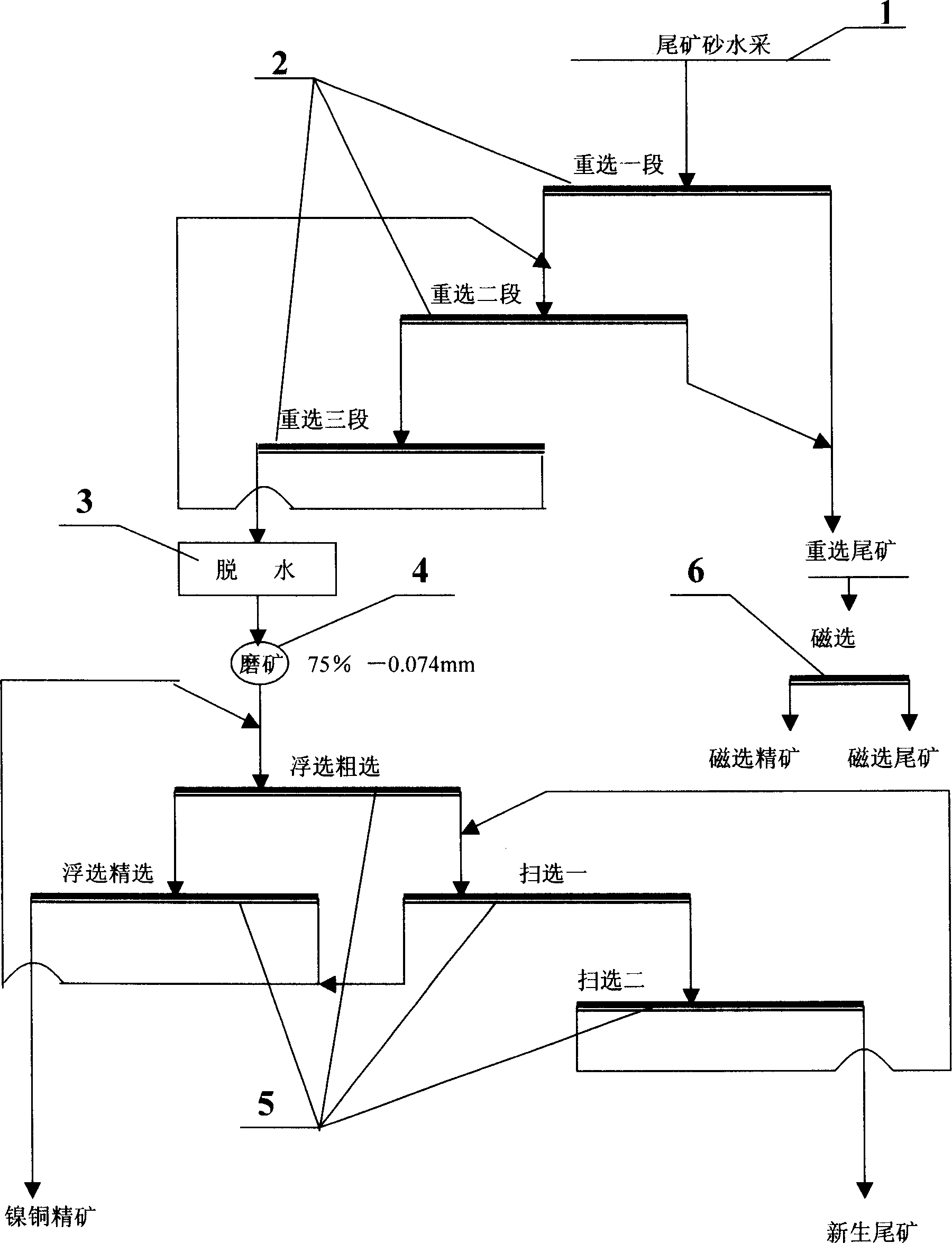

[0016] refer to figure 1 , the comprehensive recovery process of nickel sulfide and copper tailings includes the following steps in turn:

[0017] Tailings sand water mining process 1, the tailings sand is made into tailings slurry with a concentration of 20-30% by high-pressure water, and then the tailings slurry is transported to the tailings gravity separation process 2 by a mine pump.

[0018] Gravity separation process 2 is to use the difference in specific gravity and particle size of minerals, and use special gravity separation equipment such as gravity beneficiation spiral chute and jig to fully and effectively extract useful minerals and valuable metals in tailings. Gravity separation process 2 consists of three stages of separation. The products sorted in the first stage enter the second stage, the tailings after the first stage enter the magnetic separation process 6, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com