Bessemer matte production method using nickel sulfide materials

A technology of nickel sulfide and materials, which is applied in the field of non-ferrous metallurgy, can solve the problems of no application data for direct processing of nickel sulfide concentrate, etc., and achieve the effects of easy industrial application, low processing cost, and easy melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

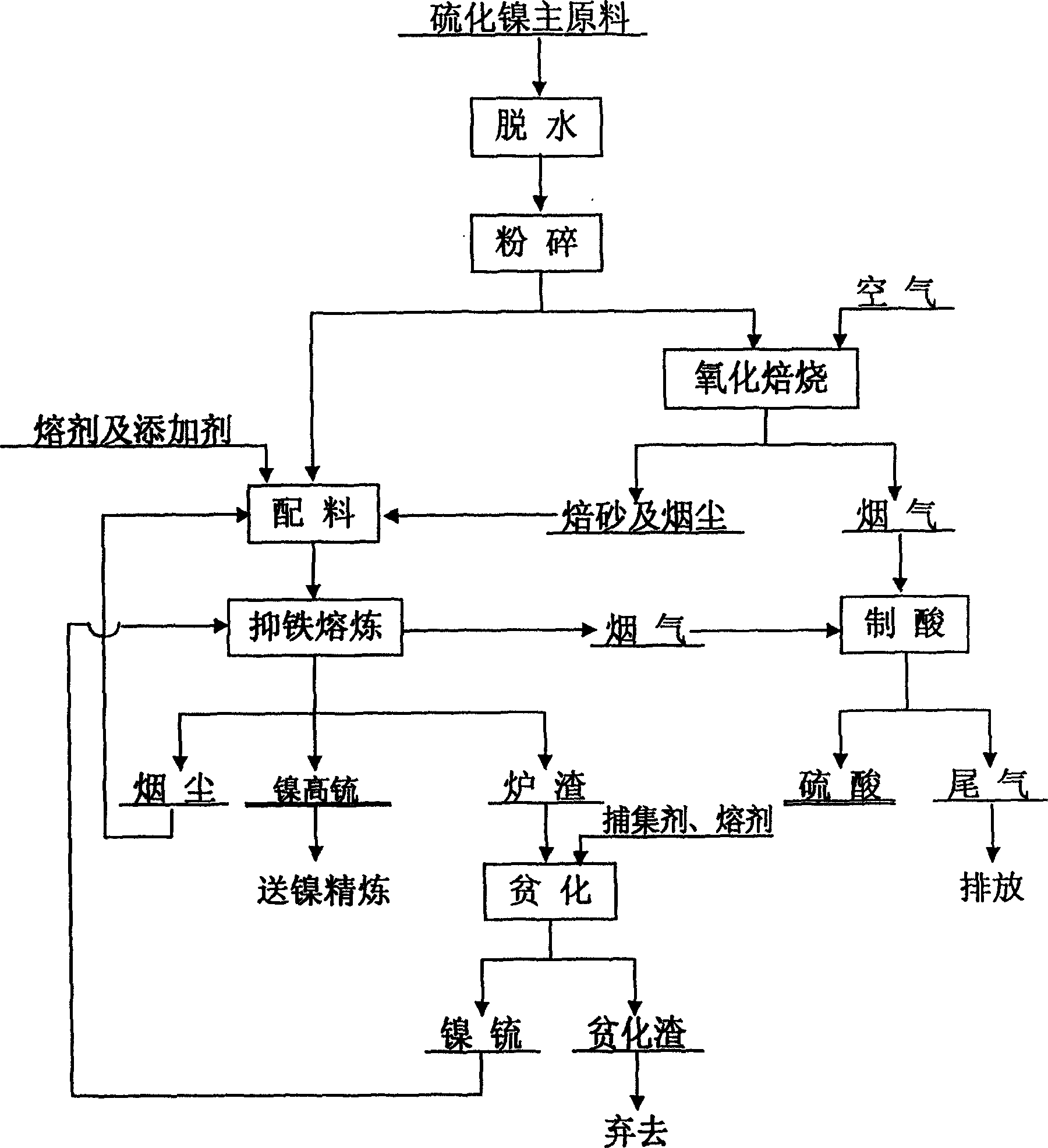

Method used

Image

Examples

Embodiment 1

[0028] Example 1: The main raw material nickel sulfide filter residue material composition is: Ni 22.10%, Co 0.44%, Fe7.86%, S 24.32%, Cu 0.03%, moisture content 53.05%.

[0029] (1) The main raw material nickel sulfide filter residue material is dehydrated to 10.2% by mass, and crushed to -1mm pulverized material;

[0030] (2) Weigh 5000g of pulverized material, 3000g of which is filled with a magnetic hair dish. In a box-type resistance furnace, at a temperature of 685°C, oxidize and roast with air as an oxidant, and the air consumption is metered in at 3650L / kg. In the furnace, the material is grilled once every 15 minutes during the roasting process, and the roasting time is 3 hours. The output calcine weighs 1828.5g, contains 6.43% S, the calcine yield is 60.95%, and the desulfurization rate is 83.88%.

[0031] (3) Get the main raw material nickel sulfide filter residue material and calcined sand according to the batching of Table 1 as 100: 91.425, mix unroasted powder m...

Embodiment 2

[0033] Embodiment 2: The main raw material and the main raw material of embodiment 1 are the same nickel sulfide filter residue pulverized material, and its composition, moisture and particle size are all the same.

[0034] (1) Weigh 5000g of crushed nickel sulfide filter residue, of which 3000g, oxidize and roast at 900°C for 2.5h, and supply air at 3370L / kg. The output calcine weighs 1514g, contains 2.46% S, the calcine yield is 50.47%, and the desulfurization rate is 94.84%.

[0035] (2) Get the main raw material nickel sulfide filter residue: calcined sand: depleted nickel matte is 100: 75.7: 12.85, mix 2000g of unroasted powder with 1514g of blast furnace calcined sand and 257g of depleted nickel matte produced in Example 1 , and according to the batching scheme 2 of aforementioned table 3 by main raw material: quartz sand: burnt lime: fluorite ore: reductant coke powder is the batching ratio of 100: 40: 22: 3: 2, adds quartz sand 2000g, burnt lime 1100g, 150g of fluorite ...

Embodiment 3

[0037] Example 3: 5000g of fine-grained high-iron copper-containing nickel sulfide material as main raw material, its composition is: Ni 22.71%, Co 0.609%, Cu 1.39%, Fe 24.33%, S 20.31%.

[0038] (1) Take 3750 g of the main raw material, use the same method as in step (2) of Example 1, oxidize and roast at a temperature of 700 ° C for 3 hours, and the amount of air is metered and supplied according to 3510 L / kg of material. The output calcine weighs 3012g, contains 6.75% S, the calcine yield is 80.32%, and the desulfurization rate is 73.30%.

[0039] (2) According to the mass ratio of main raw material and calcined sand as 100:241, 1250 g of unroasted sample is mixed with 3012 g of calcined sand, and the ingredients are prepared according to Table 2 scheme 1, according to main raw materials: blast furnace water quenched slag: quartz sand: firefly Stone ore: charcoal powder with a ratio of 100:60:20:3:1, add 3000g of blast furnace water-quenched slag, 1000g of quartz sand, 150g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com