Novel remote operation far-end robot control platform and method

A technology for controlling platforms and robots, applied in manipulators, manufacturing tools, etc., can solve the problems of difficult time delay compensation, large transmission delay, and large amount of video information, so as to achieve safe and reliable operation, improve operation efficiency, and feedback transmission time. delay effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

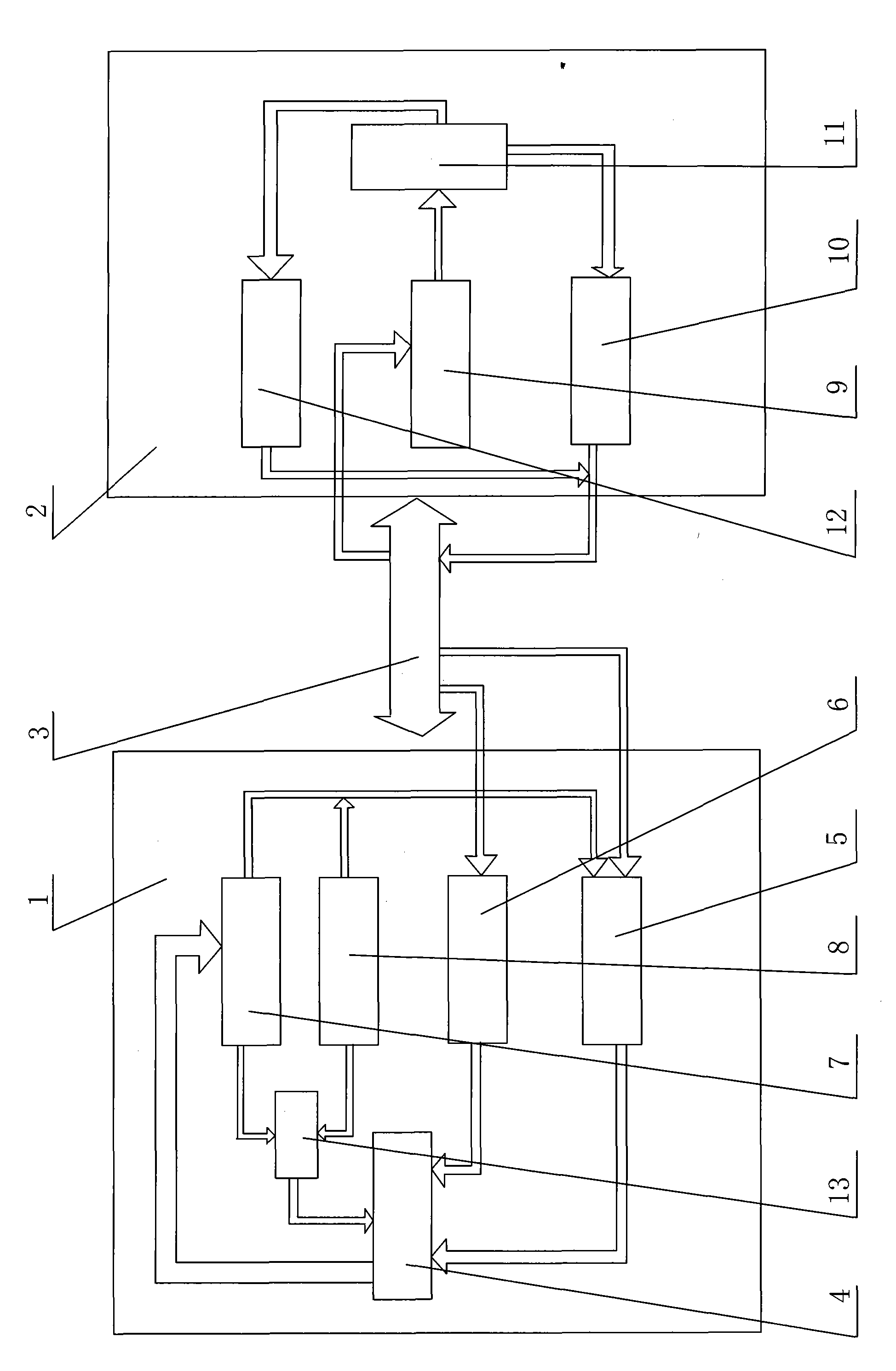

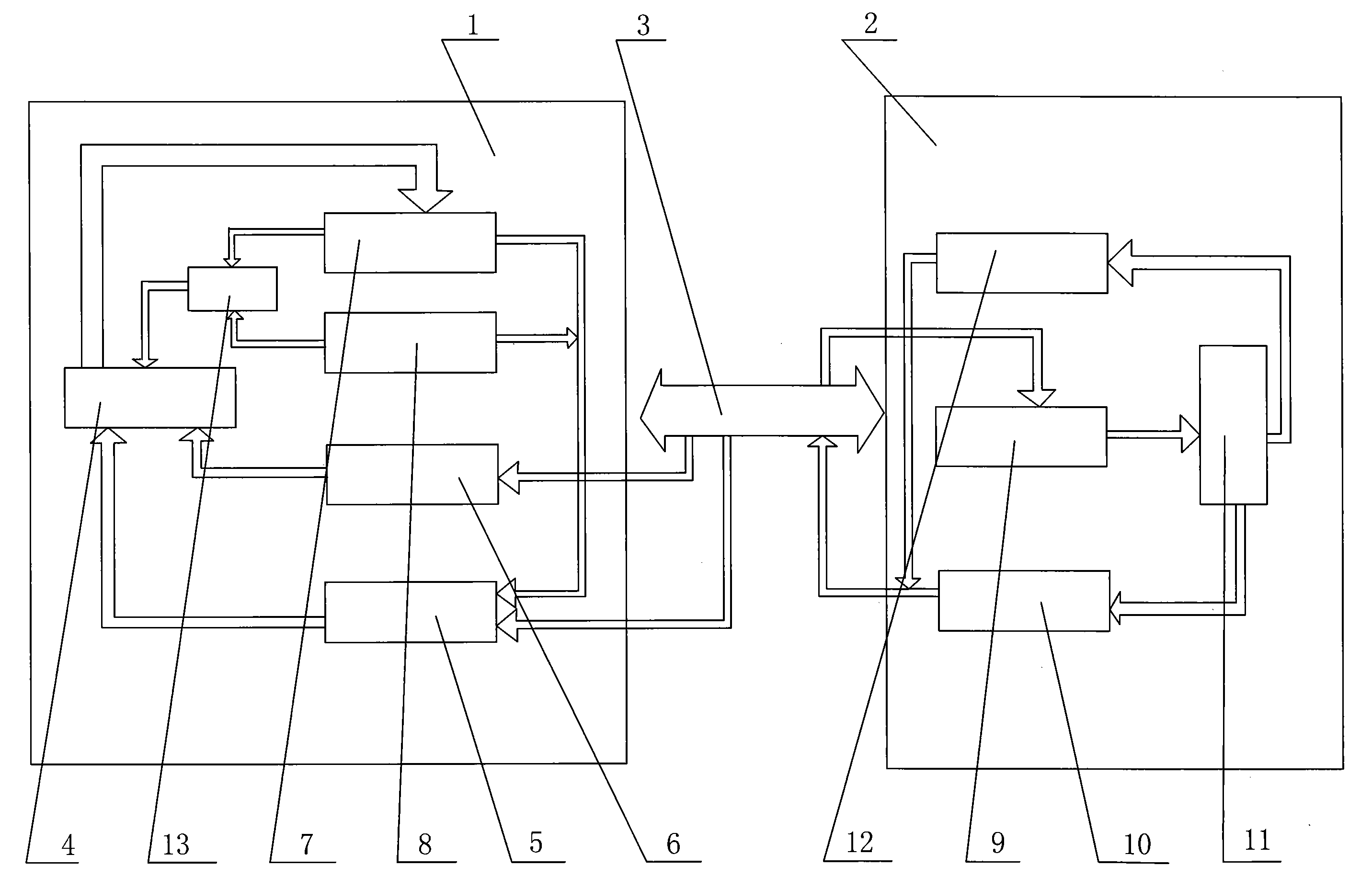

[0025] A new type of teleoperation remote robot control platform, which consists of a client terminal 1 and a server 2. The client terminal 1 transmits data 3 to the server 2 through the network, and the client terminal 1 includes a human-computer interaction device 4 The human-computer interaction device 4 is connected to the video display 5, the data comparison 6 and the virtual operation model 7 and the virtual feedback model 8 superimposed together at the same time; the server 2 includes a remote robot control unit 9, the The remote robot control unit 9 is connected to the remote robot 10, and the remote robot 10 is connected to the data acquisition unit 11 and the video monitoring device 12.

[0026] In the novel teleoperation remote robot control platform, the virtual operation model and the virtual feedback model are connected to video display, and the virtual feedback model is connected to data comparison.

Embodiment 2

[0028] In the operation method of the novel teleoperation remote robot control platform described in Embodiment 1, the operation process is to superimpose and display two virtual models—a virtual operation model and a virtual virtual feedback model—on the same display window;

[0029] The virtual virtual feedback model is synchronized with the motion of the real remote robot. The operator simulates the motion of the remote robot through the virtual operation model, and sends the motion information to the remote remote robot, and the virtual virtual feedback model's motion It is controlled by the motion feedback information of the remote robot;

[0030] The feedback information is real-time joint motion sensor information, with small data and small time delay, and the accumulated motion error caused by the time delay can be compensated by model angle compensation, so that the motion of the virtual virtual feedback model and the motion status of the real remote robot be consistent;

...

Embodiment 3

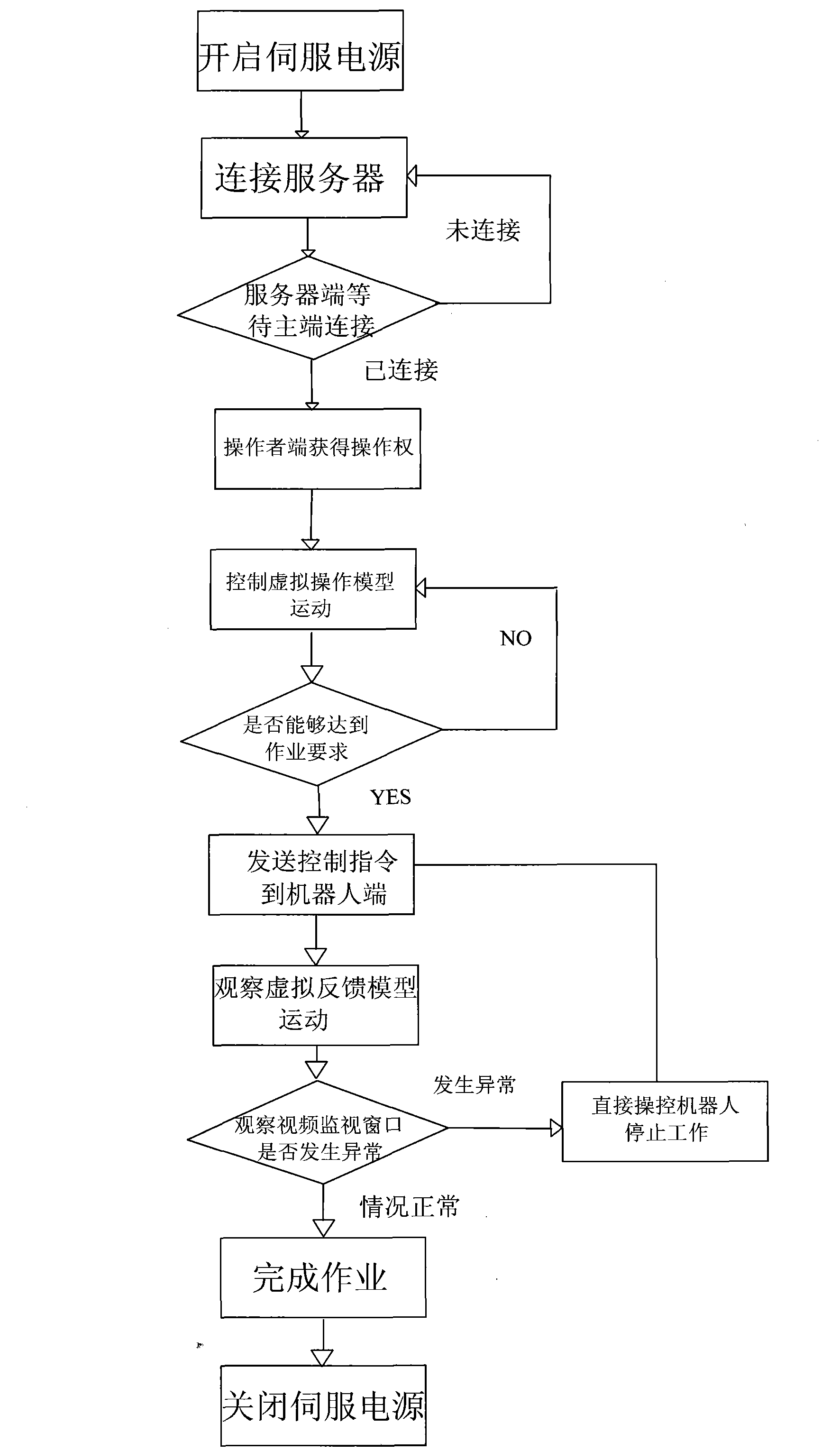

[0037] The operation method of the novel teleoperation remote robot control platform described in embodiment 1 or 2, the operation flow is,

[0038] (1) Turn on the system servo power, plan the remote robot's operating trajectory, and the client side controls the virtual operating model, and observe whether its running trajectory meets the operating requirements, including whether the obstacle avoidance is smooth and the final pose positioning is accurate. If you want to observe the movement status of the virtual operation model in detail, select the drawing trajectory to draw a detailed trajectory, and you can get a clear trajectory of the virtual operation model in the display window.

[0039] (2) If the virtual operation model meets the corresponding job requirements, the client side sends running instructions to the remote real remote robot, and the real remote robot moves at the same time and sends data back to the virtual virtual feedback model in real time to ensure that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com