Automatic feed electric screwdriver

An electric screwdriver, automatic feeding technology, applied in screwdrivers, power tools, wrenches and other directions, can solve the problems of low work efficiency, great difficulty, difficult installation, etc., to achieve the effect of not easy personal injury accident, safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

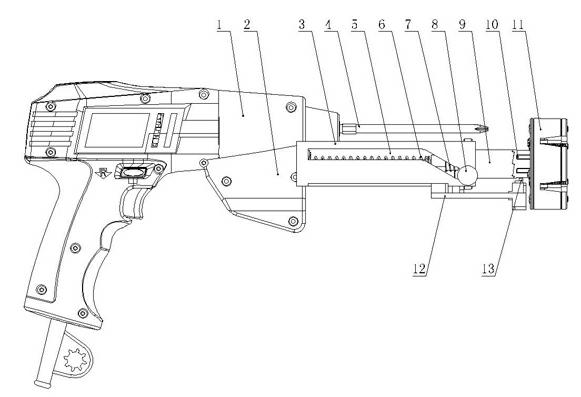

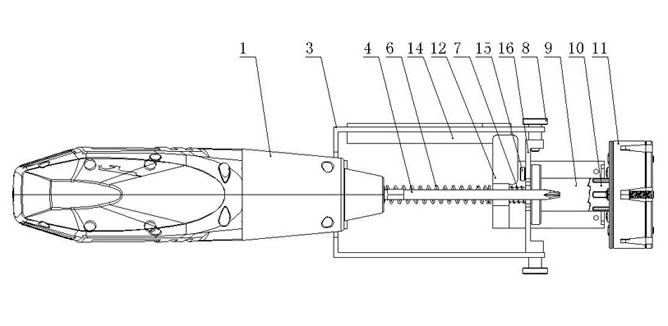

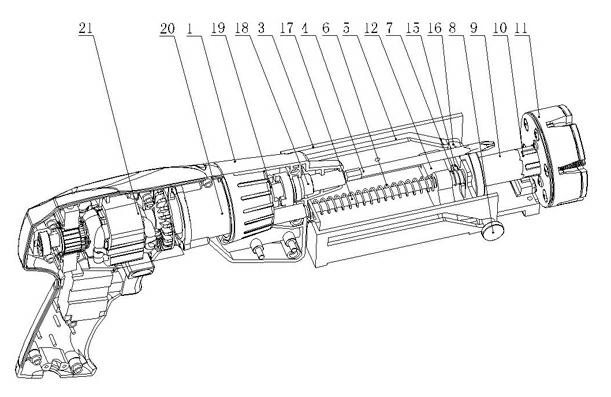

[0025] Figure 1 to Figure 7 Shown, for the present invention creates the specific embodiment of automatic feed electric screwdriver, it comprises body 1, screwdriver 4, fixed base 2, motor 21, deceleration mechanism 20, clutch mechanism 19, output shaft 18, screwdriver are installed in body 1 4 is installed on the output shaft 18, the fixed seat 2 is integrated with the body 1 or fixedly connected, the fixed seat 2 is provided with a guide sleeve 27, the fixed seat 2 is fixed with a chute frame 3, and the chute frame 3 A chute 5 and a slide rail 14 are provided, the front section of the chute 5 is a chute or an arc groove, the rear section is a straight groove, and the chute frame 3 is provided with a reset guide rod 17 parallel to the screwdriver 4 and can move linearly. One end of the reset guide rod 17 passes through the guide sleeve 27 and is limited by the stop pin 26. The other end of the reset guide rod 17 is successively provided with a back-moving spring 6, a screw d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com