Mining method with adjustable and controllable structure size of gentle dip medium-thickness ore body strip column reconstructed stope

A technology with a gentle slope, medium thickness and structural size, which is applied in ground mining, underground mining, special mining, etc. It can solve the problems of difficulties in mining pillars, inability to recover, and large-scale filling of goafs that cannot be mined out, so as to achieve less filling materials. , high production efficiency and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

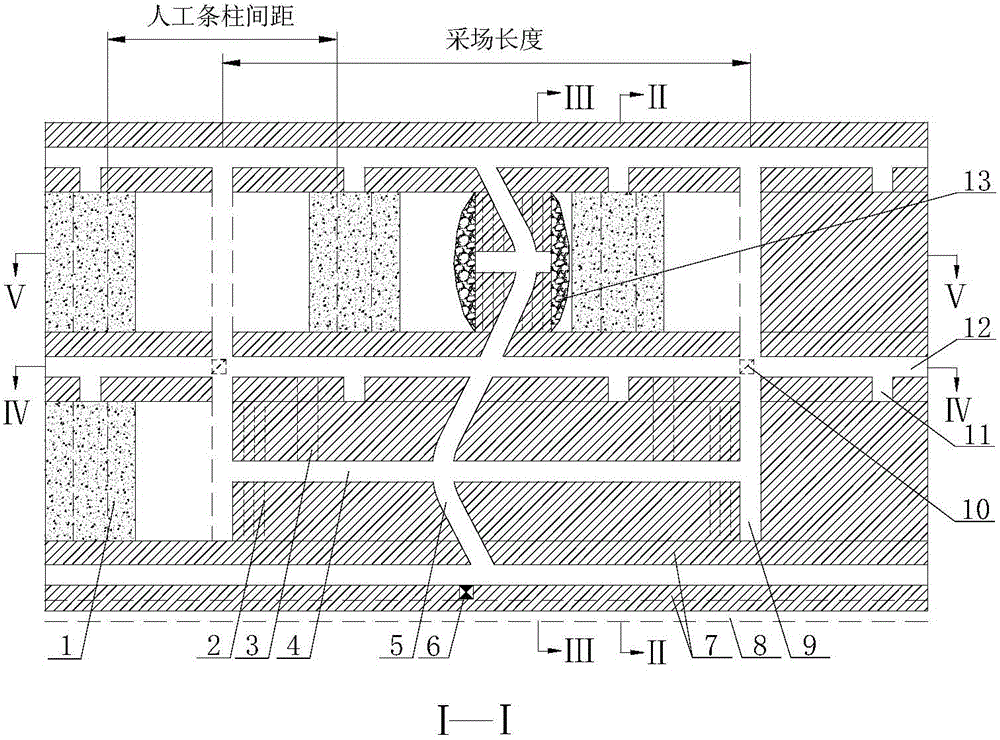

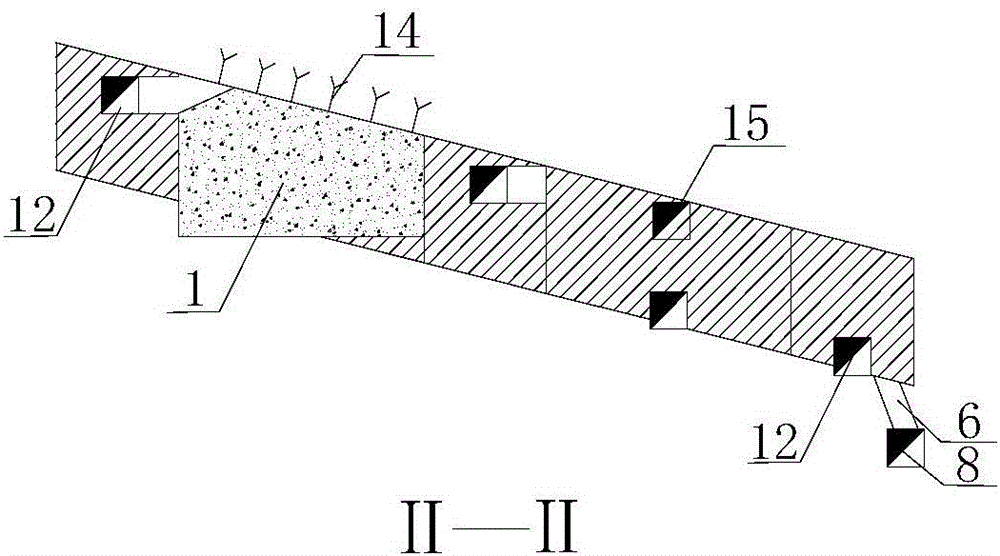

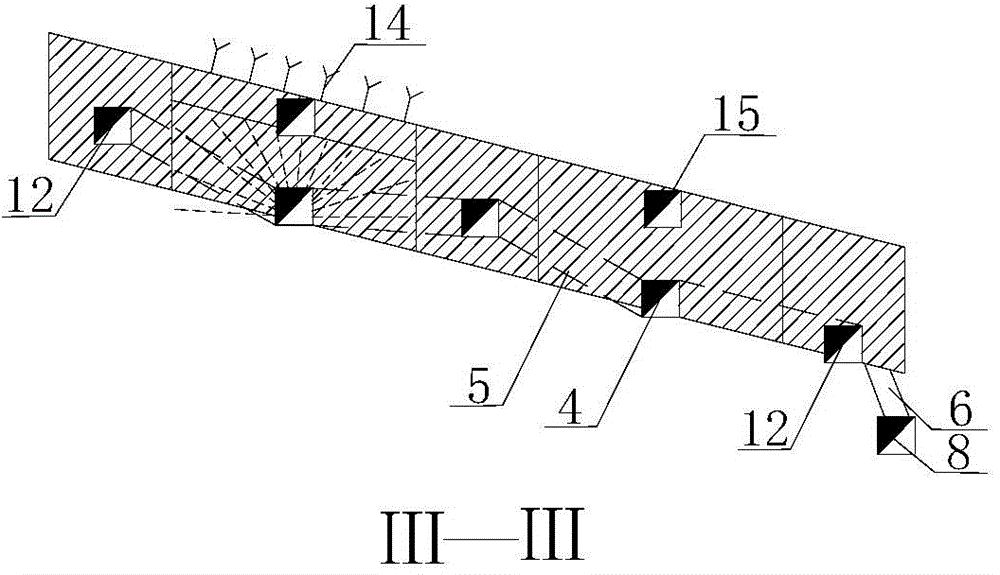

[0025] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , divide the panel along the ore body trend, divide the panel into sections, and leave continuous pillars 7 along the strike between the sections. The structural size of the continuous pillar 7 is 10m, the stope width is 20m, and the length is 80m. The stope is arranged along the strike, and the stopes of each section are connected by the turn-back mining quasi-slope 5, and the chute 6 is arranged in the continuous ore pillar at the bottom of the panel, and the stage transportation roadway 8 of the footwall of the ore body is connected to form a middle transportation system. A roof cutting roadway 15 is arranged in the middle of the stope roof, and is connected with the filling roadway 12 through the roof cutting connecting road 3. Excavate the rock-drilling ore-out approach 4 from the mining slope to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com