Deep hole underwater installation and locating method of steel pipe column in weak watery stratum

It is a technology for installation and positioning and weak ground, which is applied in the treatment of underwater structures, water conservancy projects, and building materials. It can solve the problems of complicated procedures, difficult precision, and high construction costs, and avoid the uncontrollability of loose contact. Improved work accuracy and low construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention can be explained in more detail with reference to the following examples; however, it should be noted that the present invention is not limited to the following examples.

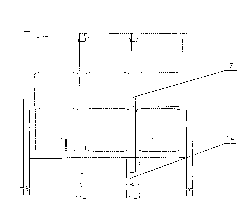

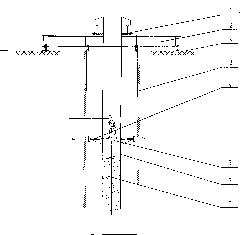

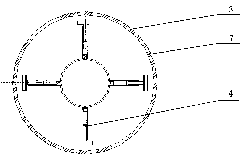

[0045] combined with Figure 2~4 The installation and positioning method of the steel pipe column in the deep hole underwater in the water-rich and weak stratum firstly pours concrete 6 of a certain height in the steel pipe column 7, and then installs it; The mud 9 and the buoyancy in the concrete in the bored pile 3, the second is to use the concrete 6 in the steel pipe column to block the mud 9 in the bored pile from entering the steel pipe column 7, and provide conditions for the construction workers 5 to locate the middle and lower parts of the steel pipe column 7; and The steel pipe column 7 is installed by a two-point positioning method, one point is located on the ground surface, and one point is located in the hole of the bored pile 3; the ground surface uses a positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com