Underwater automatic docking mechanism for ROV

An automatic docking and mounting seat technology, which is applied to underwater operation equipment, transportation and packaging, ships, etc., can solve the problems of difficult maintenance or replacement of underwater equipment, limited grasping ability of ROV manipulators, etc., to ensure safe operation and ensure The effect of detachment and simple mechanism structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

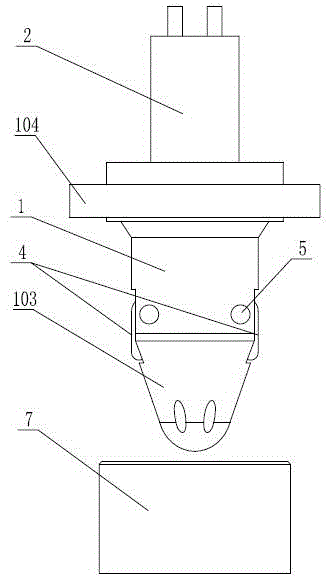

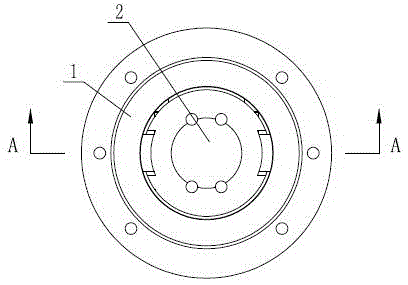

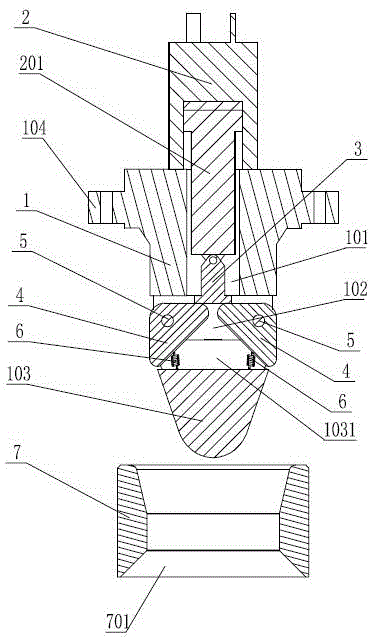

[0018] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0019] See figure 1 , figure 2 , image 3 , the present invention includes a mounting base 1, and a T-shaped through groove is arranged in the mounting base 1, and the T-shaped through groove includes an axial hole 101 and a radial through groove 102; the cylinder body of the oil cylinder 2 is fixed on one end of the mounting base 1 , the piston rod 201 of the oil cylinder 2 extends into the axial hole 101, and the end of the piston rod 201 is hinged with a push head 3; There is a radial channel 2 1031 on the end, and the radial channel 1031 and the radial channel 102 communicate with each other and connect to form an installation space. Two locking blocks 4 are provided in the installation space, and the two locking blocks 4 are locked. The block 4 is symmetrically arranged on both sides of the push head 3, and the locking block 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com