Building glass waste separating device

A technology for separating devices and architectural glass, which is applied in cleaning devices, transportation and packaging, conveyor objects, etc., and can solve the problems of glass waste that cannot be separated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

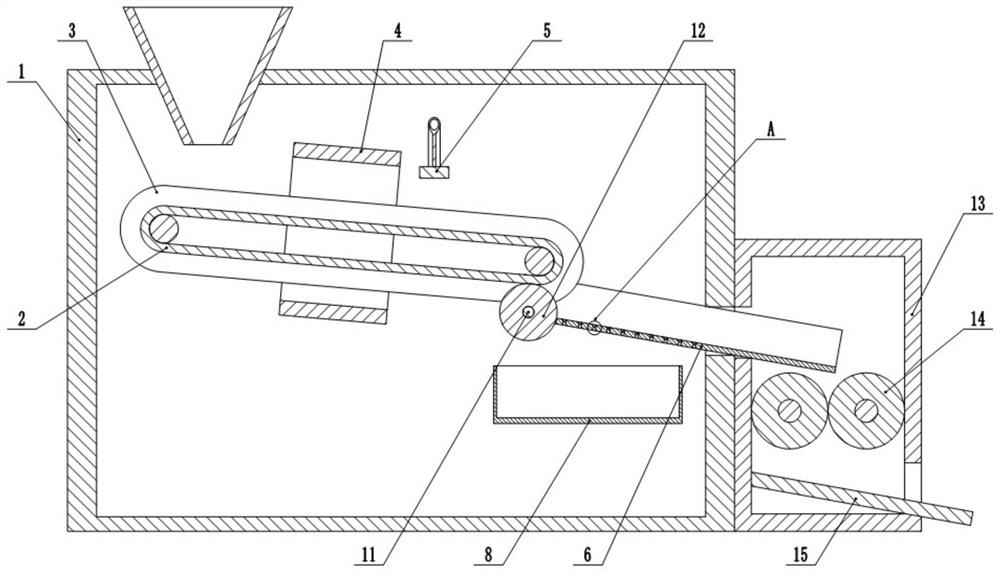

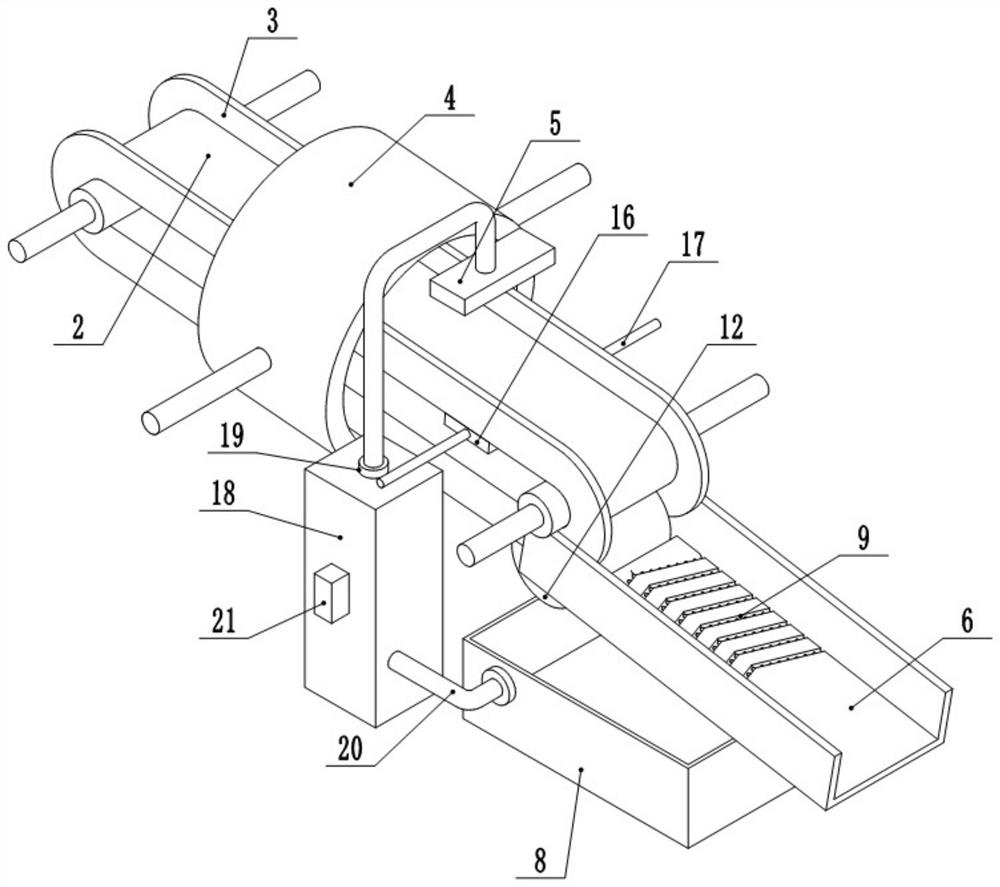

[0024] Such as figure 1 , figure 2 and image 3 Shown:

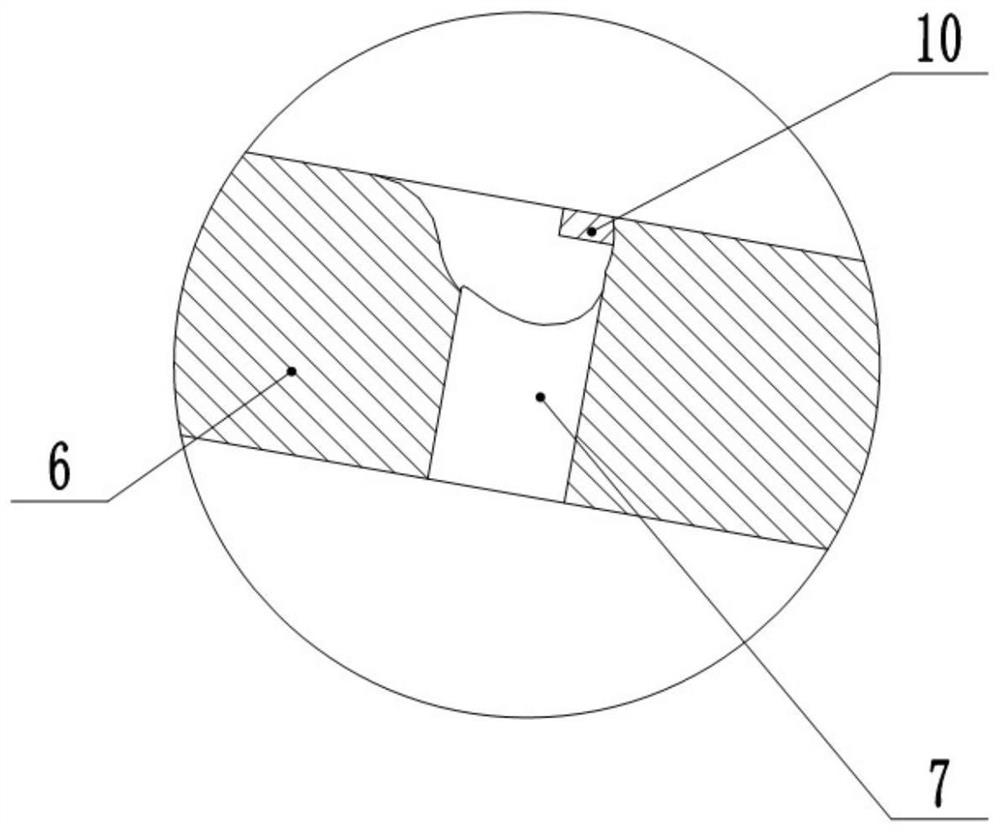

[0025] A construction glass waste separation device, including a crushing box 1, and a crushing device and a separation device located in the crushing box 1, an inclined conveyor belt 2 is arranged in the crushing box 1, and baffles 3 are integrally formed on both sides of the conveyor belt 2, and the crushing device It includes a heating device and a cooling device arranged in sequence along the conveying direction of the conveyor belt 2. The heating device includes an electromagnetic heating ring 4. Both sides of the electromagnetic heating ring 4 are fixedly connected to the inner wall of the crushing box 1 through a support rod 17, and the electromagnetic heating ring 4 is set on the conveyor belt. 2; the cooling device includes a water tank 18 and a water pump 19, the water tank 18 is connected to the bottom of the crushing box 1 by bolts, the top of the conveyor belt 2 is provided with a shower head 5 facing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com