Ununiformity emendation real-time calibration apparatus for staring type thermal imaging system

A technology of non-uniformity correction and calibration device, applied in the direction of electric radiation detector, etc., can solve the problem of poor correction effect and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings.

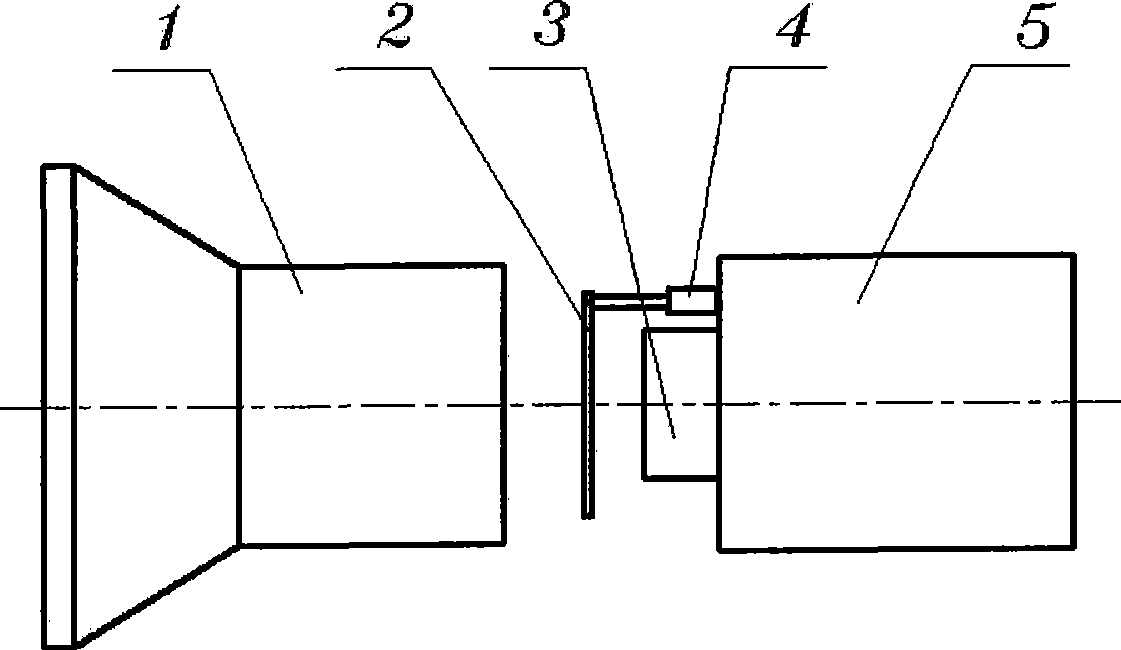

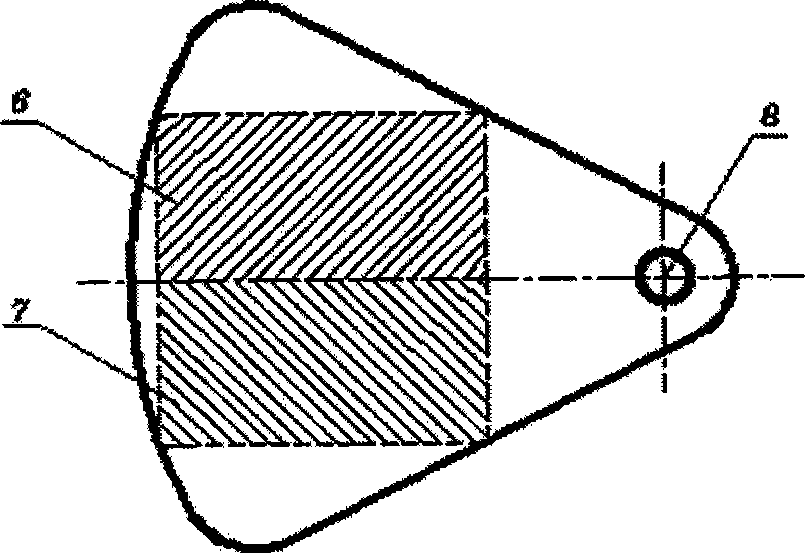

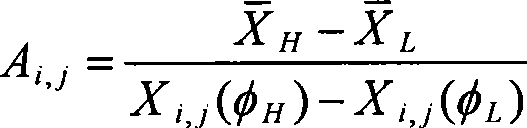

[0048] combine figure 1 , the non-uniformity correction real-time calibration device of the staring thermal imager of the present invention comprises an infrared lens 1, an equivalent high and low temperature reference black body block 2, an infrared detector 3, a stepping motor 4 and a signal processing control circuit 5, located in the infrared The equivalent high and low temperature reference black body block 2 between the lens 1 and the infrared detector 3 is connected to the rotor of the stepping motor 4, and the power supply and control port of the stepping motor 4 are connected to the signal processing control circuit 5; the infrared lens 1 is used to target The infrared radiation is focused on the focal plane of the detector; the equivalent high and low temperature reference blackbody barrier 2 is used for real-time high and low temperature calibration of non-u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com