Braze alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

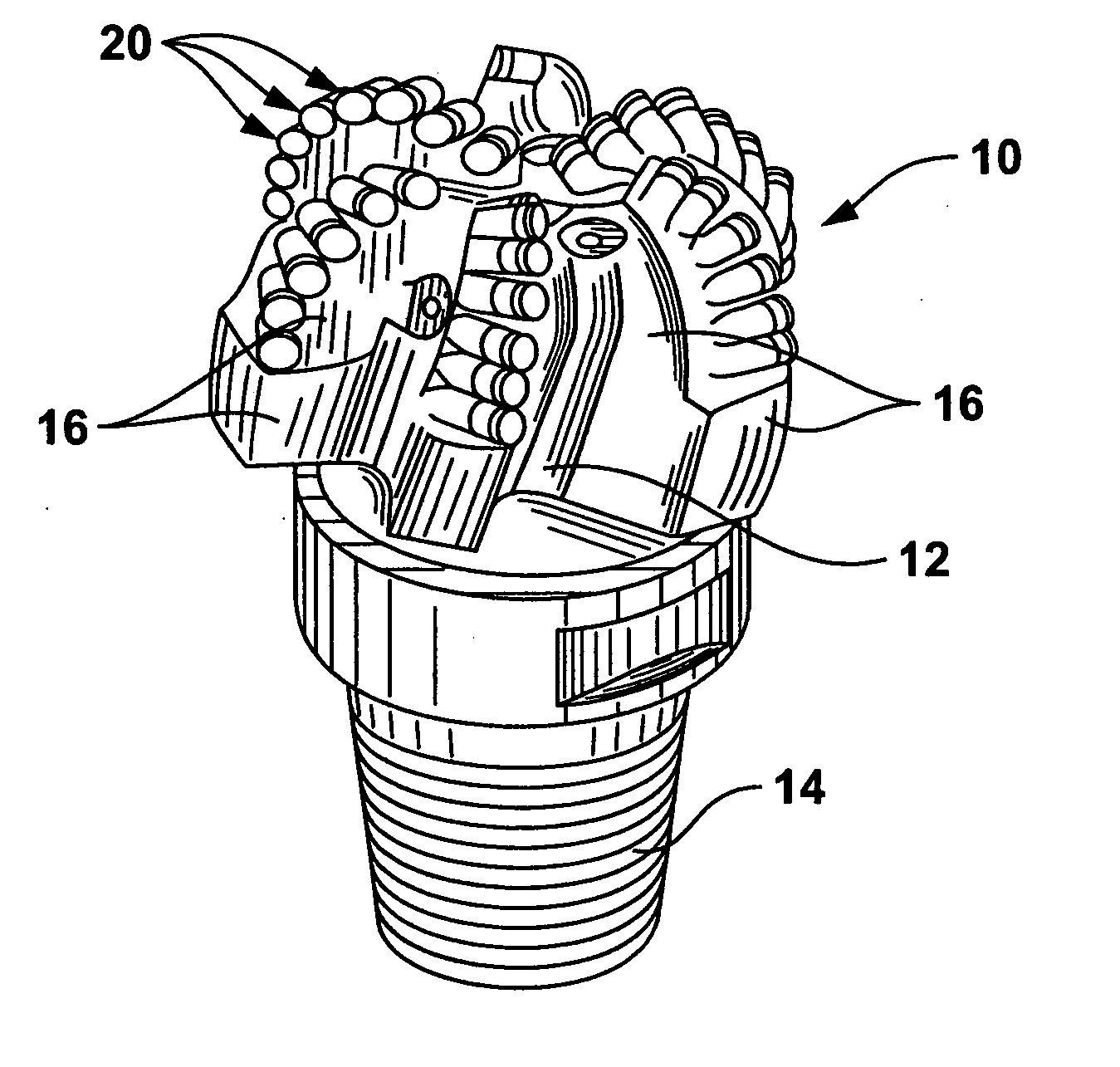

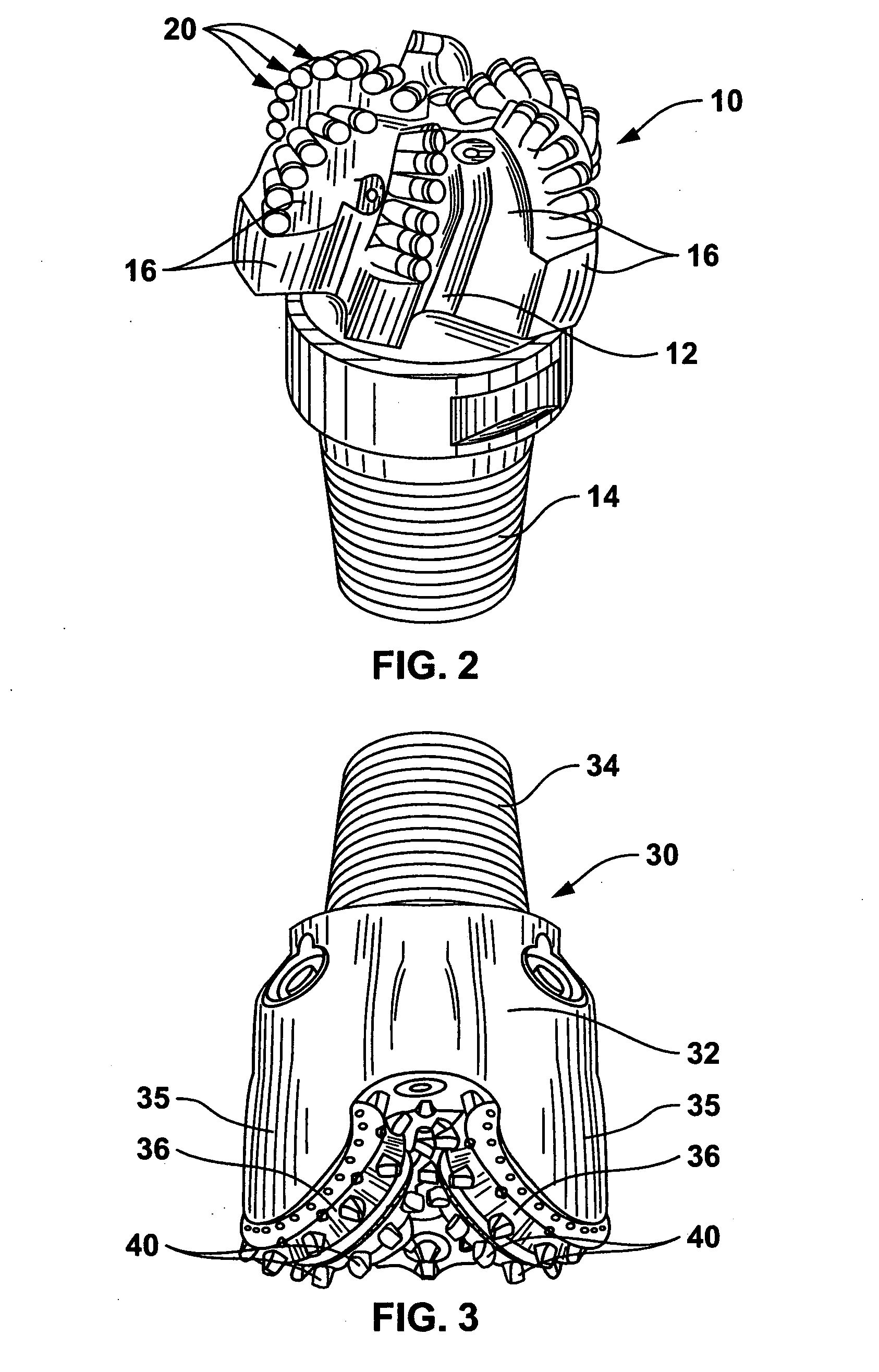

[0022] The present invention provides a braze alloy that includes one or more alloying elements to reduce braze temperature. In one or more embodiments, the alloying elements may also increase braze strength. Braze alloys in accordance with one or more embodiments of the invention may be used in drilling tool applications, such as for brazing cutting elements in a drilling tool, as described below.

[0023] In one embodiment, a method for brazing a cutting element to a drill bit includes placing braze alloy into a cavity of a cutting element support structure of the drill bit. The braze alloy includes about 0.5% to about 10% by weight of at least one selected from the group of gallium (Ga), indium (In), thallium (Tl). The method also includes inserting at least a portion the cutting element into the cavity. The method further includes heating the braze alloy such that it melts between the cutting element and the cavity, and cooling the braze alloy to form a bond between the cutting el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com