Device and method for manufacturing carbon fiber reinforced composite construction member

A reinforced composite material and manufacturing device technology, applied in the field of carbon fiber reinforced composite material component manufacturing device, can solve the problems of large cutting force, high cutting temperature, severe tool wear, etc., and achieve improved production efficiency, small equipment investment and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be described in detail below by describing the embodiments in conjunction with the accompanying drawings.

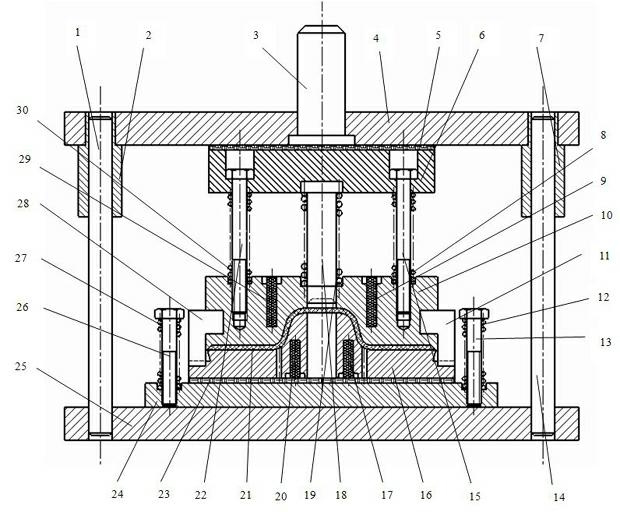

[0028] The overall structure of the manufacturing device of the carbon fiber reinforced composite component involved in this embodiment is as follows: figure 1As shown, it is composed of three parts: a mold base, an upper mold and a lower mold, wherein the upper mold base plate 4 and the lower mold base plate 25 are guided by the guide post 1, the guide sleeve 2, the guide post 14, and the guide sleeve 7 to form a basic mold base. , the upper mold part is connected with the punching machine through the mold handle 3, and the lower mold part is fixed on the machine tool table through the lower mold seat plate 25. For large parts, the guide plate can also be used to guide, and the upper mold fixed plate is directly connected with the pressure. Machine slider connection.

[0029] The lower mold part is composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com