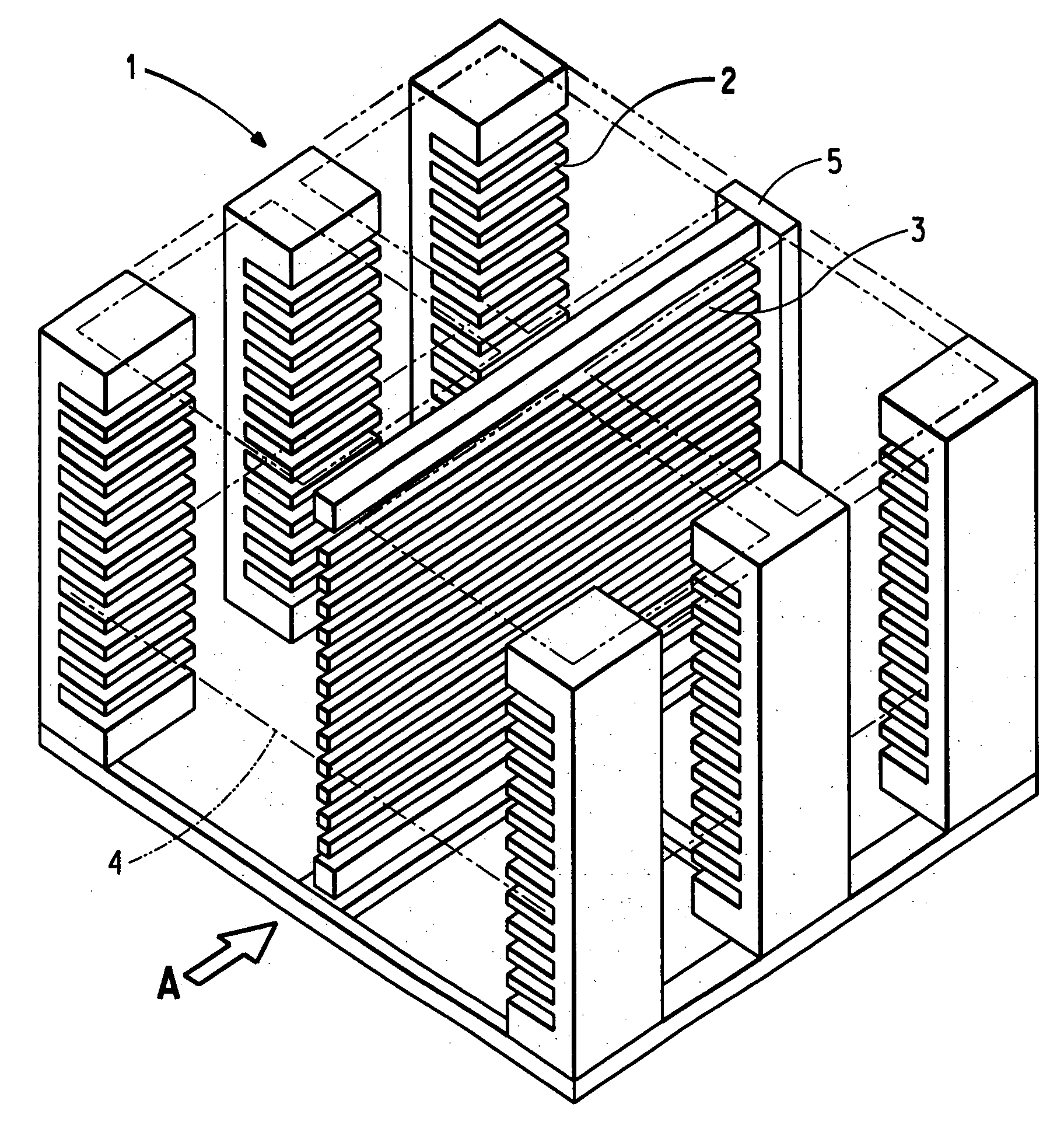

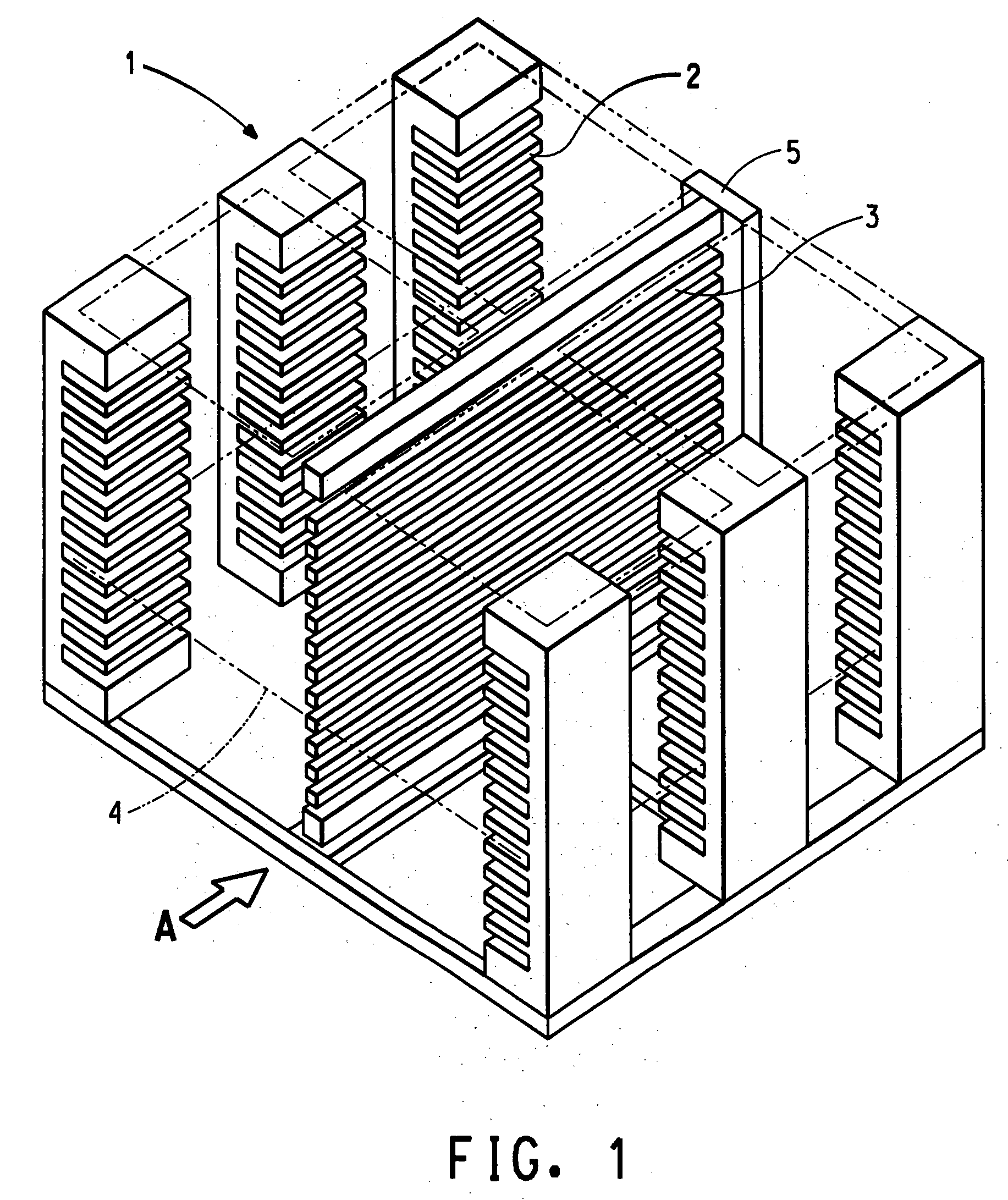

Supporting bar for substrate cassette

a technology of supporting bar and substrate, which is applied in the direction of damagable goods packaging, transportation and packaging, packaging goods type, etc., can solve the problems of reducing production efficiency, unable to suppress the warping at the central part of the glass substrate, and the transfer fork cannot carry smoothly the substra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

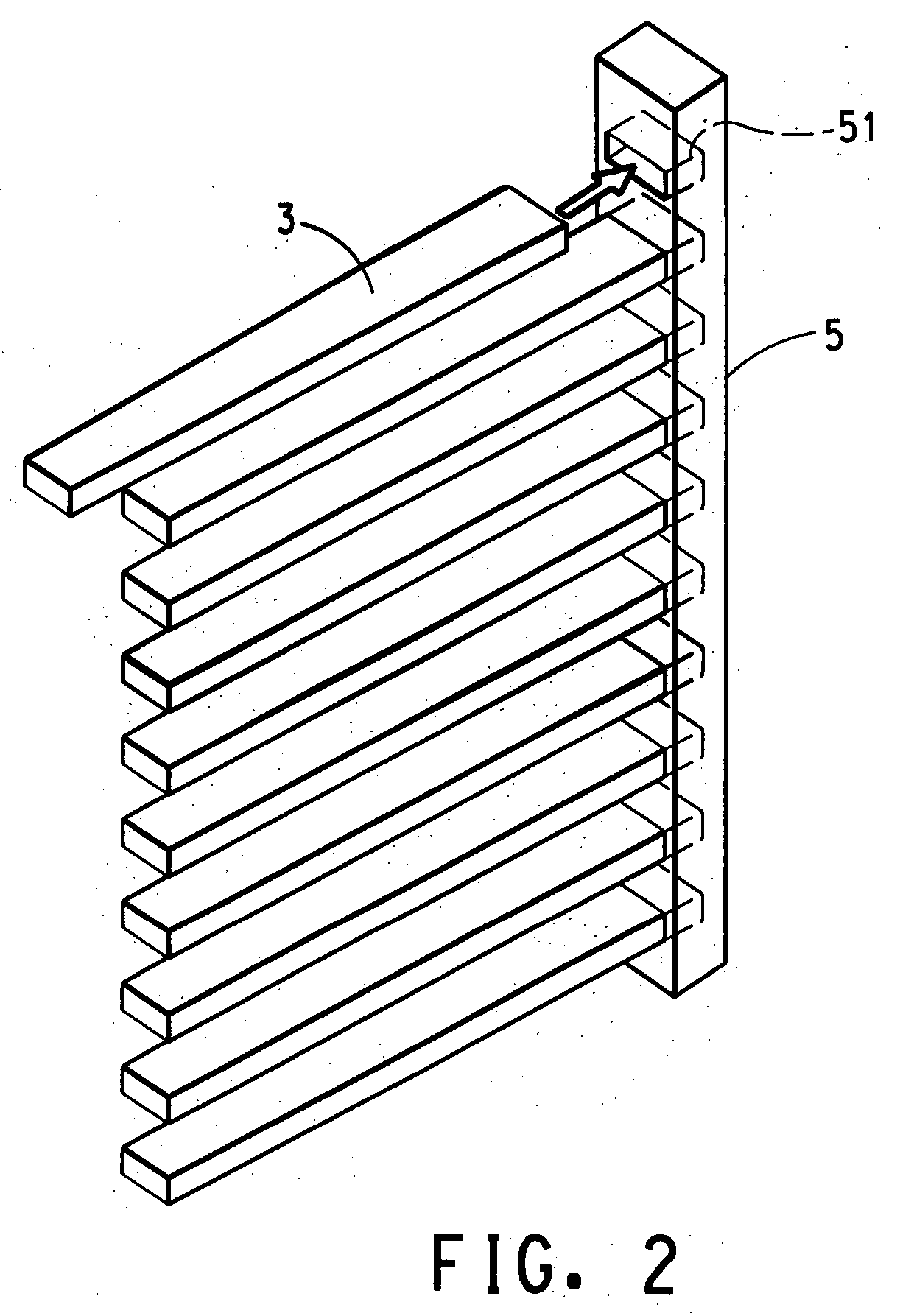

execution example 1

[0097] After preparing a trapezoidal aluminum removable core with a height of 6.9 mm, a width of 54.9 mm in a fixed end, and its width of 24.9 mm in a tip part as a removable core, the prepreg sheet B in which pitch system carbon fibers with its tensile elasticity of 240 GPa was oriented at 90 degrees in the longitudinal direction of the removable core, the prepreg sheet A in which pitch system carbon fibers with its tensile elasticity of 800 GPa was oriented at 0 degrees in the longitudinal direction of the removable core, and a cross prepreg sheet C which was oriented at 0 degrees and 90 degrees for the outer layer were laminated to the removable core in this order in the numbers listed in the Table 1 and were hardened by heat. After it was hardened, the removable core was taken out, and then a support bar in the shape of a hollow trapezoid with a taper with its width of 60 mm in a fixed end, its width of 30 mm in a tip part, its height of 12 mm, its wall thickness of 2.55 mm, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com