Aluminium screw-on packaging jar and manufacturing method thereof

A production method and technology of packaging cans, which can be applied to other household utensils, bottles, household utensils, etc., can solve the problems of low-grade products, high production costs, moisture-proof, waterproof, and poor anti-counterfeiting, and achieve simple processing methods and a high degree of automation , good anti-counterfeiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

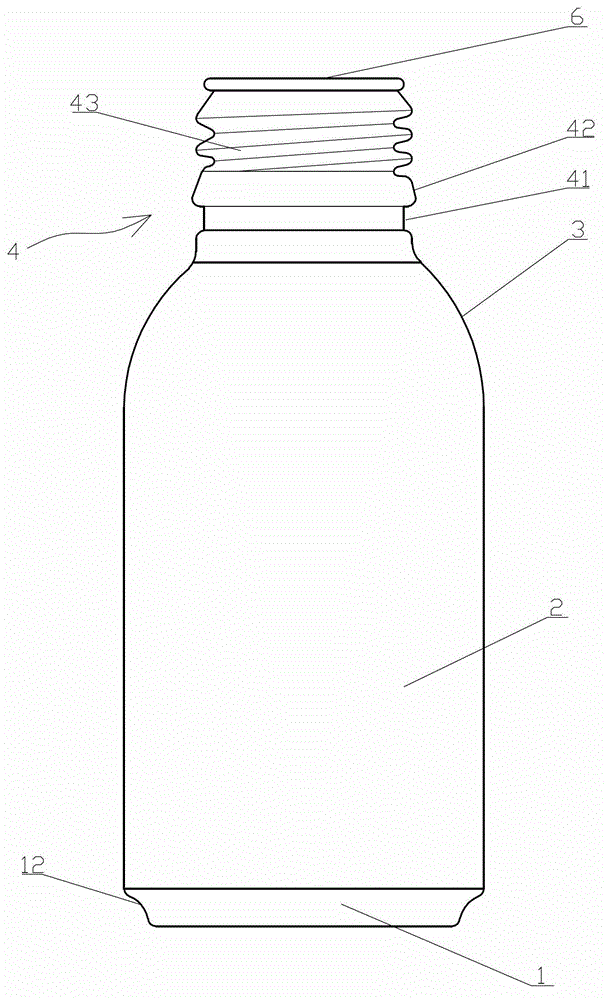

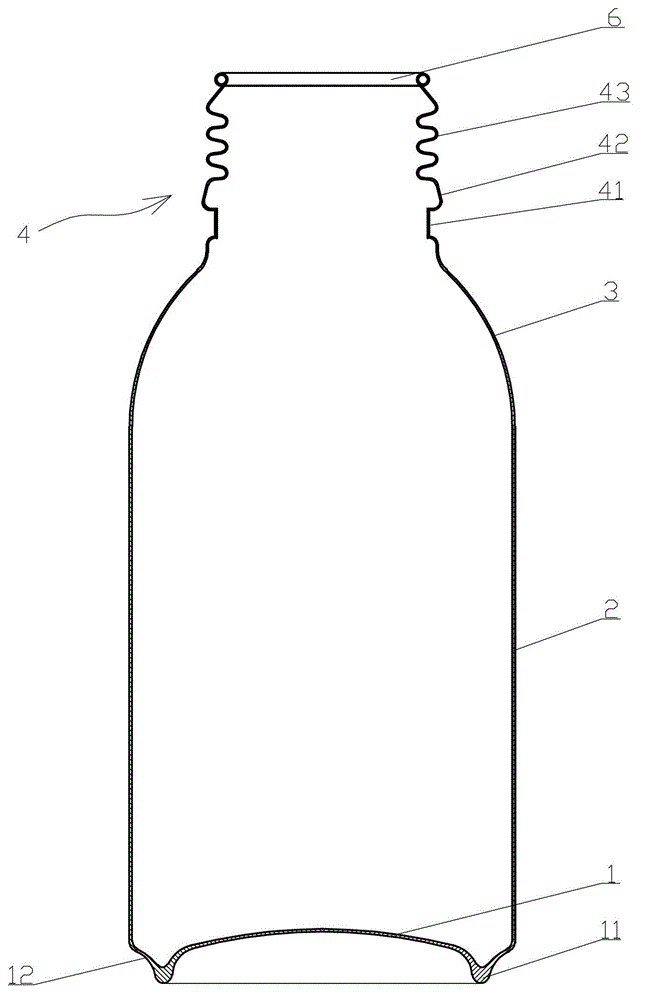

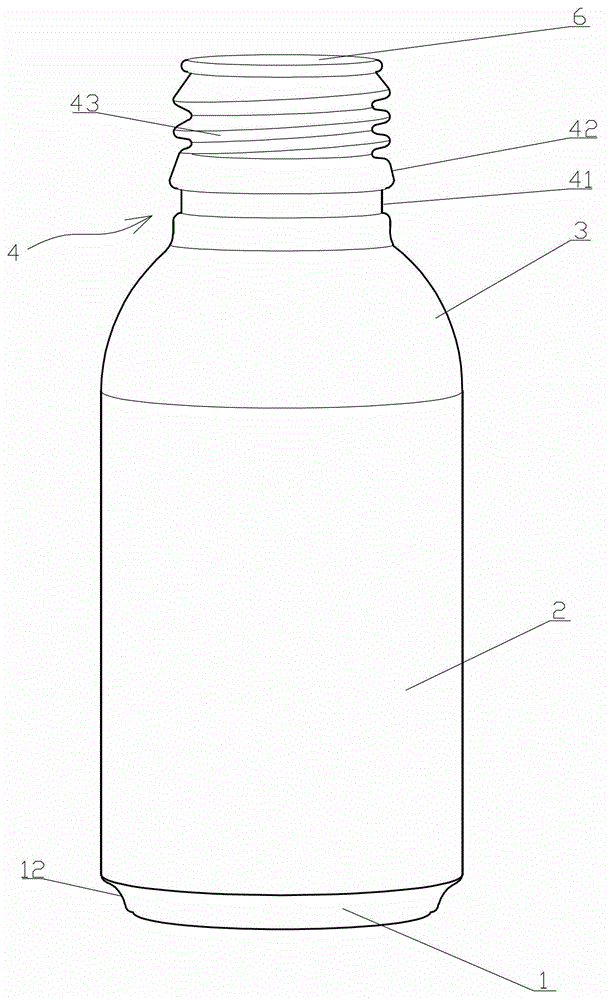

[0028] Such as Figure 1 to Figure 3 As shown, an aluminum screw-top packaging can includes a can bottom 1, and the bottom 1 of the can is provided with a bottom edge 11 that is extruded downward and protrudes downward from the bottom 1 of the can, and the edge of the bottom edge 11 extends upward with a can barrel 2. The bottom edge 11 is connected to the tank 2 through a transitional arc 12 that is concave inward to the tank 2, so that the compression and torsion resistance of the bottom of the bottle can be strengthened. The tank 2 shrinks upward to form a tank shoulder 3 , the lower part of the section of the tank shoulder 3 is an arc convex to the tank 2 , and the upper part is an arc concave in the tank 2 . The tank shoulder 3 shrinks upwards to form a tank neck 4. The tank neck 4 is provided with an annular groove 41 and an inclined prot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com