Auxiliary frame structure of concrete mixer truck

A technology for concrete mixer trucks and sub-frames, which is applied to the substructure, vehicle parts, transportation and packaging, etc., and can solve problems such as poor ability to withstand impact and alternating stress, weld cracks, and inability to guarantee concrete mixer trucks. , to improve the anti-torsion strength and ensure the effect of safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

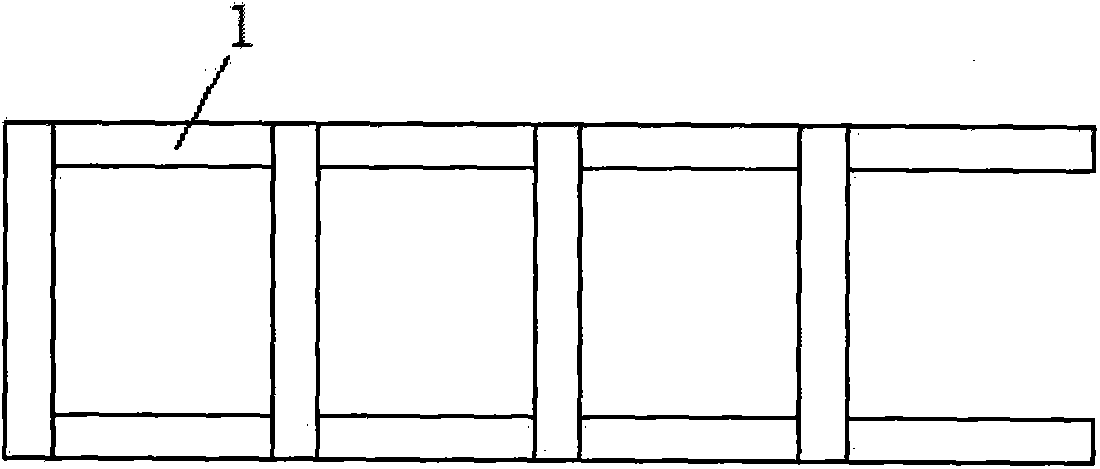

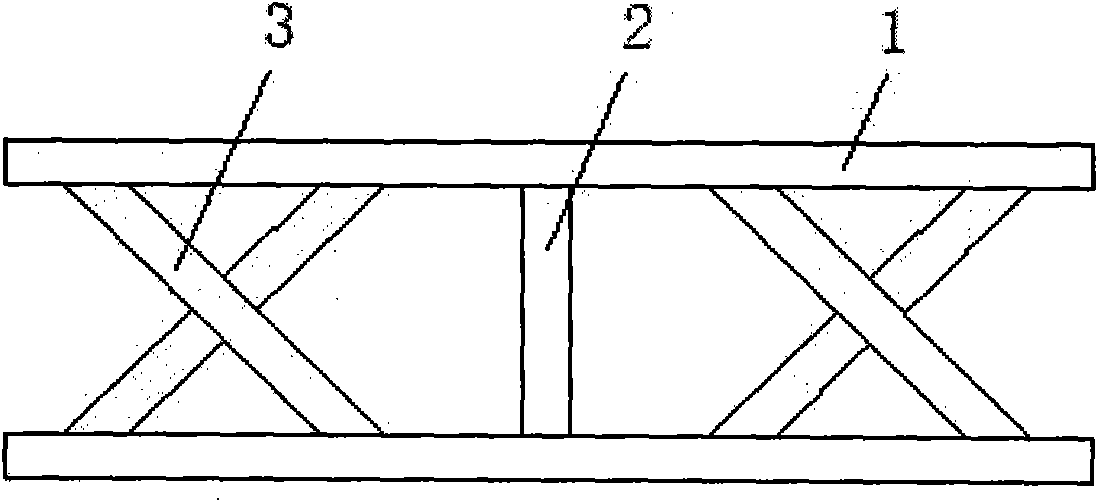

[0011] Such as figure 2 As shown, the present invention is mainly composed of a longitudinal beam 1 and a crossbeam. The longitudinal beam 1 is connected with a middle beam 2 and an X beam 3. The X beam 3 is composed of two beams to form an X-shaped structure. The middle beam 2 is located in the middle of the longitudinal beam 1, the middle beam 2 and the longitudinal beam 1 are perpendicular to each other, the X beam 3 is located on both sides of the middle beam 2, the four ends of the X beam 3 are connected with the longitudinal beam 1, by setting the X Beam 3 is used to improve the torsional strength of the subframe of the mixer truck.

[0012] The above is only a preferred embodiment of the present invention, but the scope of protection of the present invention is not limited thereto. Anyone familiar with the technical field within the technical scope disclosed in the present invention, according to the technical solution of the present invention Any equivalent replaceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com