An easy-to-assemble drag chain with high twist resistance and its preparation method

A technology with anti-distortion and high strength, which is applied in the field of drag chains, which can solve problems such as troublesome assembly, high processing costs, and complex structures, and achieve the effects of compact structure, improved overhead performance, and increased bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

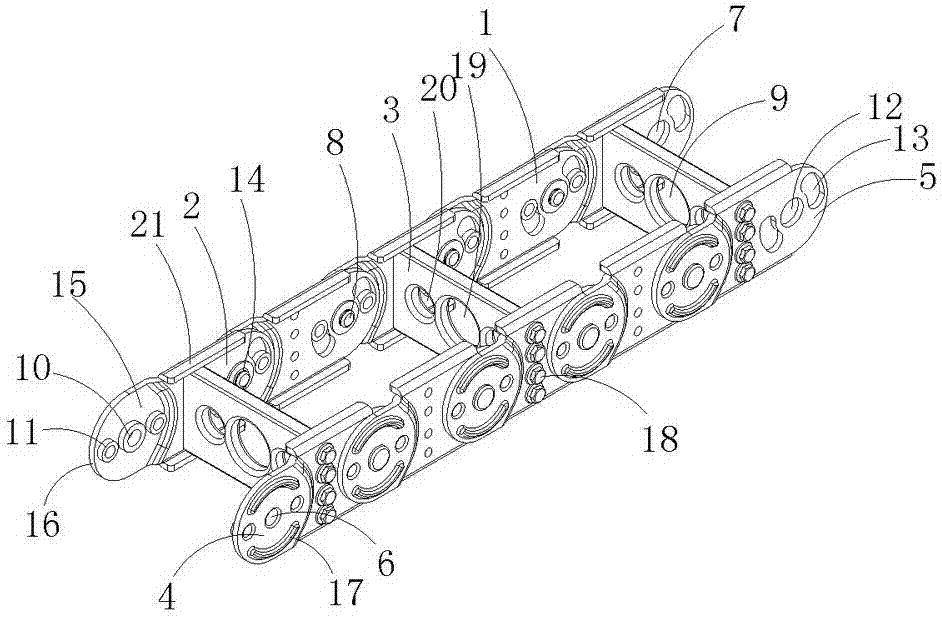

[0031] Embodiment 1: as figure 1 As shown, a tow chain that is easy to assemble and has high anti-torsion strength, the tow chain is composed of successively distributed chain links 1, the described chain links 1 include a pair of symmetrically distributed chain plates 2, and the chain plates 2 are supported by The plates 3 are positioned in phase, the head of the chain plate 2 is provided with a head connecting end 4 integrated therewith, and the tail of the chain plate 2 is provided with an integrated tail connecting end 5, the The head connecting end 4 of the chain link 1 is provided with a positioning boss 6, and the tail connecting end 5 is provided with a positioning hole 7 matched with the positioning boss 6, and the head connecting end 4 of the chain link 1 is connected with another chain The tail connection end 5 of the section 1 is matched and fixed, the positioning boss 6 and the positioning hole 7 are fixed by the positioning pin 8, the chain plate 2 is compos...

Embodiment 2

[0052] Embodiment 2: a kind of preparation method of the tow chain that is easy to assemble anti-torsion strength is high, carries out according to the following steps:

[0053] (1), blanking and forming:

[0054] Firstly, the steel plate required for the towline is cut with a laser cutting machine. The power of the laser machine is 2500W, the size of the laser head is 0.5 inches, the focal length of the lens is 5.00, the slit width of the laser machine is 0.15 mm, and the nozzle of the laser machine The diameter is 0.8mm, the cutting speed of the laser machine is 5000mm / min, and the cutting time of each single section is 1 minute. Oxygen is used for cutting, and the unloaded workpiece is placed on the transfer trolley;

[0055] (2), forming and heating:

[0056] Install the workpiece on the transfer trolley to the mold in the press. The pressure of the press is 150,000 kg, and the forming time of the press is 2 minutes. Take it out and wait for use; weld the two c...

Embodiment 3

[0067] Embodiment 3: a kind of preparation method of the towline that is easy to assemble anti-torsion strength is high, carries out according to the following steps:

[0068] (1), blanking and forming:

[0069] Firstly, the steel plate required for the towline is cut with a laser cutting machine. The power of the laser machine is 2500W, the size of the laser head is 0.5 inches, the focal length of the lens is 5.00, the slit width of the laser machine is 0.15 mm, and the nozzle of the laser machine The diameter is 0.8mm, the cutting speed of the laser machine is 5000mm / min, and the cutting time of each single section is 1 minute. Oxygen is used for cutting, and the unloaded workpiece is placed on the transfer trolley;

[0070] (2), forming and heating:

[0071] Install the workpiece on the transfer trolley to the mold in the press. The pressure of the press is 150,000 kg, and the forming time of the press is 3 minutes. Take it out and wait for use; weld the two c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com