Drag chain capable of protecting cable and production method of drag chain

A drag chain and cable technology, applied in the field of drag chains, can solve the problems of weak bearing capacity, small overhead length of drag chains, complex structure, etc., and achieve the effect of increasing bearing capacity, improving overhead performance, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

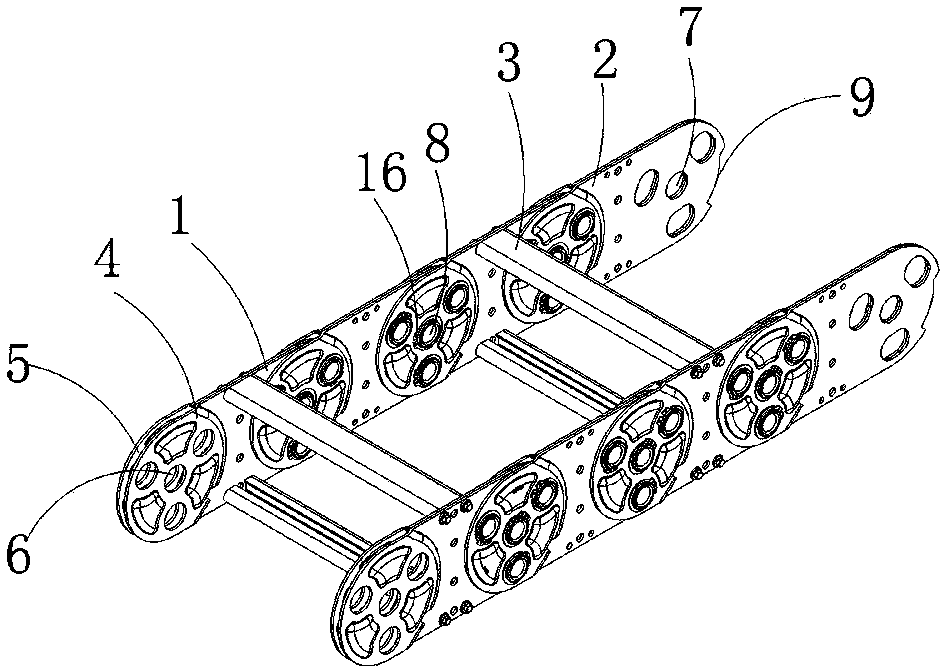

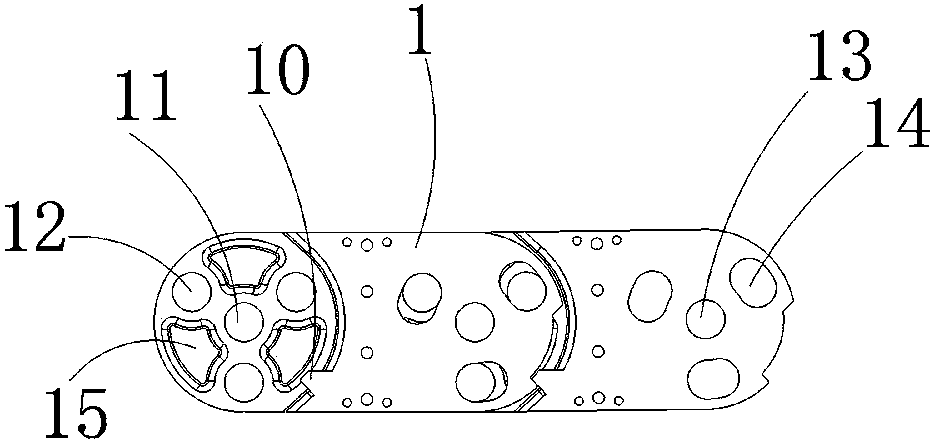

[0032] Embodiment 1: as figure 1 and figure 2 As shown, a drag chain for protecting cables is composed of successively distributed chain links 1. The chain links 1 include a pair of symmetrically distributed chain plates 2, and the chain plates 2 are positioned by supporting plates 3. The head of the chain plate 2 is provided with a chain sleeve 4 integrated with it, the chain sleeve 4 is provided with a chain sleeve chamber 5, and the chain sleeve 4 is provided with a front positioning pin hole 6, so that The tail of the chain plate 2 described above is provided with the rear positioning pin hole 7 corresponding to the front positioning pin hole 6, the tail of the chain link 1 is inserted into the chain sleeve cavity 5 of another chain link 1, the front positioning pin hole 6 is connected with the rear positioning pin hole The positioning pin holes 7 are fixed by the limit pin shaft 8, the outer wall of the tail of the chain link 1 is provided with a rear limit notch 9, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com