Steel-plastic composite steady-state pipe

A steel-plastic composite, stable pipe technology, applied in pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of pipe bursting, reducing the compressive strength of steel-plastic pipes, and the steel-plastic contact layer is easy to peel off each other. , to achieve the effect of strengthening the strength and improving the anti-torsion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with embodiment, but is not limited to the content on the description.

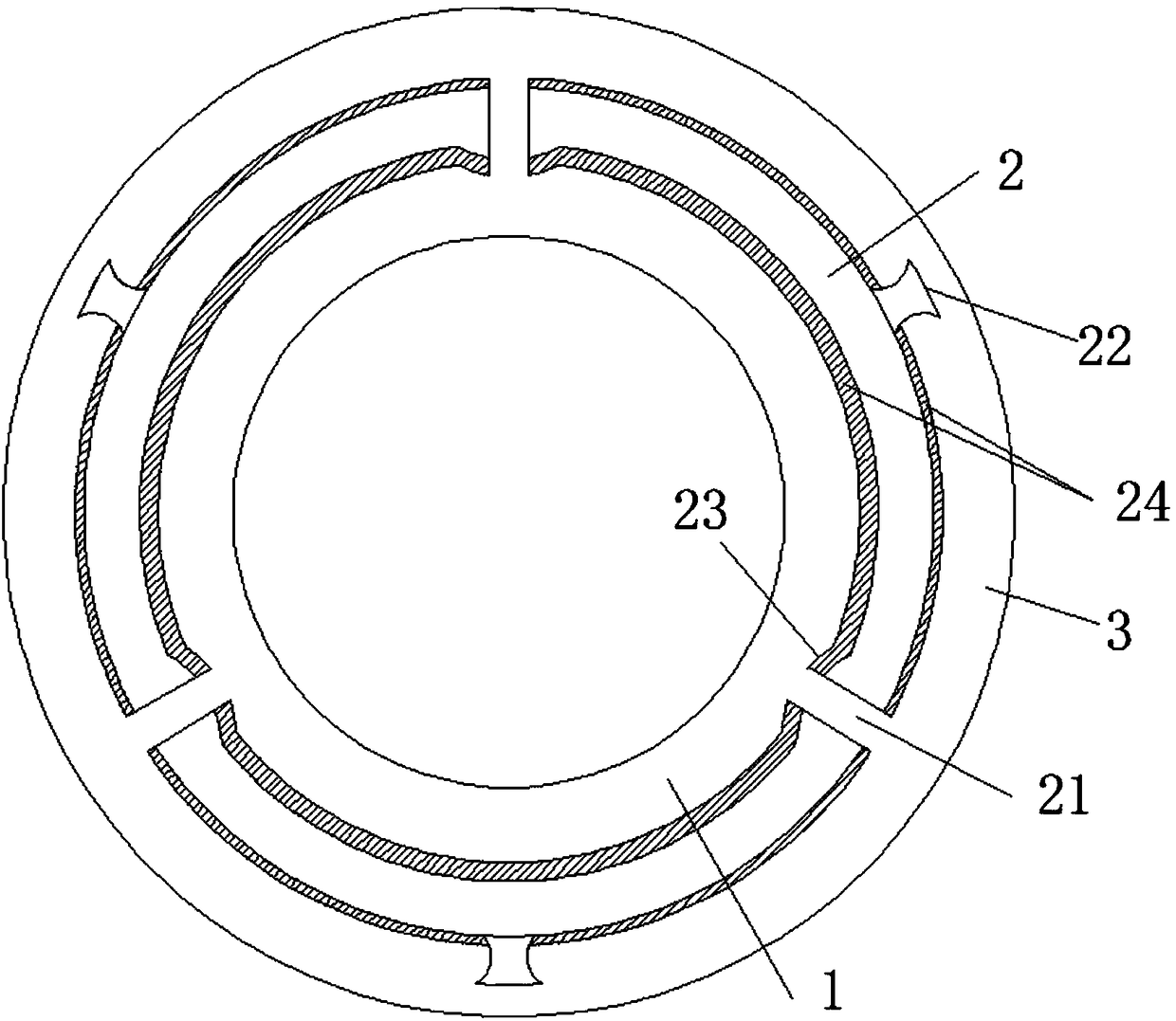

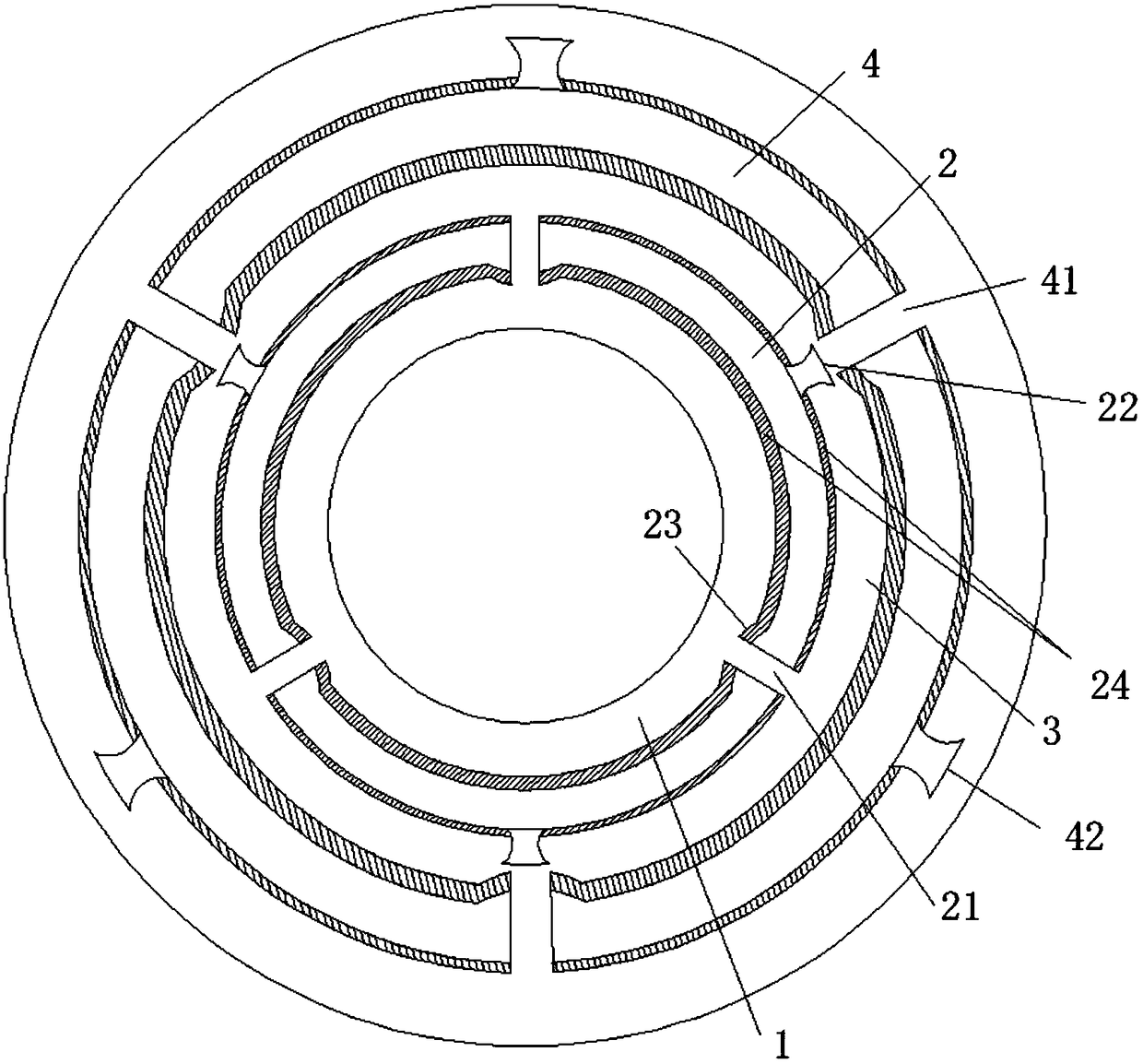

[0021] Example 1, such as figure 1 Shown: a steel-plastic composite stable pipe, which includes a plastic inner layer 1, a steel pipe layer 2 and a plastic outer layer 3, and the steel pipe layer 2 is arranged between the plastic inner layer 1 and the plastic outer layer 3.

[0022] The steel pipe layer 2 is a hot-dip galvanized steel pipe. The surface of the hot-dip galvanizing is provided with an organic passivation film layer 24. The surface of the hot-dip galvanizing is passivated with an organic passivating agent. On the one hand, the corrosion resistance of the steel pipe layer 2 can be enhanced. On the one hand, the adhesion between the surface of the steel pipe layer 2 and the plastic inner layer 1 and the plastic outer layer 3 can be enhanced, so that the bonding strength between the steel pipe layer 2 and the plastic inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com