Automotive radiator high in firmness and low in leakage rate

An automotive radiator, firmness technology, applied in the direction of machine/engine, engine cooling, engine components, etc., can solve the problems of increased calibration process, high labor costs, easy deformation quality, etc., to reduce the return rate, weaken the stretching Strength, good contact sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

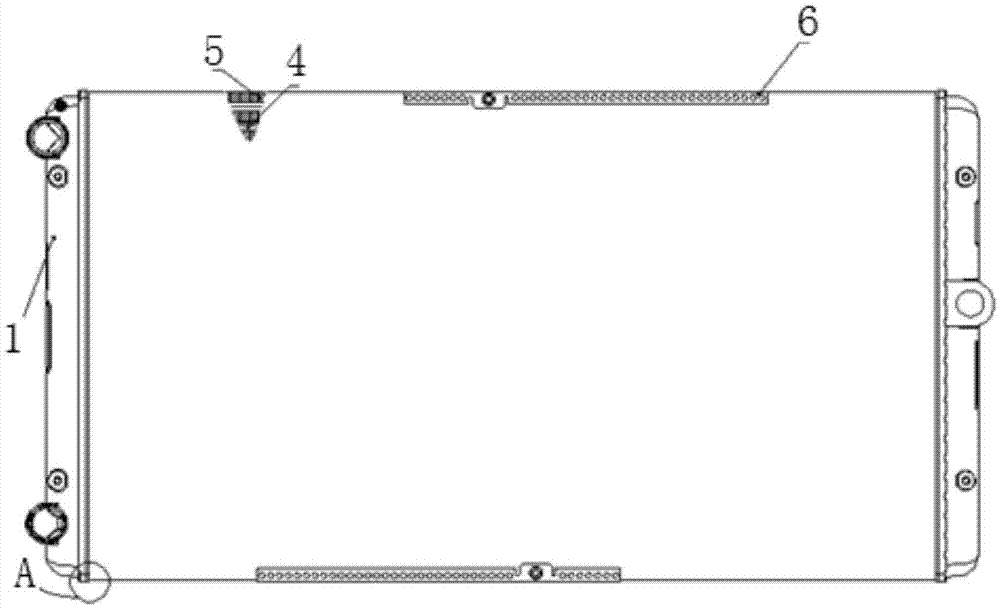

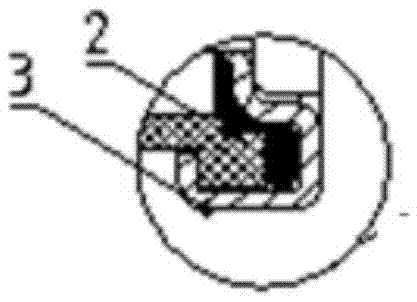

[0038] Such as figure 1 , figure 2 As shown, a car radiator with high firmness and low leakage rate includes water chamber 1, main sheet 3, heat dissipation pipe 4, heat dissipation fin 5 and side plate 6, and main sheet 3 is connected with water chamber 1, heat dissipation pipe 4 and The side panels 6 are connected.

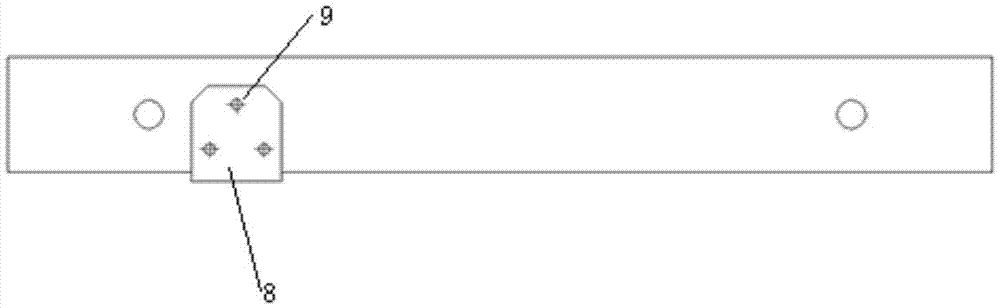

[0039] Wherein, the side plate 6 is a U-shaped plate, and the U-shaped plate includes two parallel side walls 62, such as Figure 5 As shown, there are threaded mounting holes 61 on the side wall 62 for installing cooling fans, and there are a plurality of reinforcing holes 64 on the side wall 62, which can effectively strengthen the anti-torsion effect of the side plate compared with the flat plate shape without holes. The strength function prevents the radiator core from deforming and leaking. Since the side plate 6 is stamped and formed as a whole, the original such as image 3 , Figure 4 The bracket 8 shown does not need the step of manually driving t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com