Non-woven air filter element air inlet pipe winding machine and winding process thereof

An air filter and non-woven technology, which is applied to the non-woven air filter air intake pipe winding machine and its winding process field, can solve the problems of poor bending strength performance, poor anti-aging performance, short service life, etc., and achieve anti-twisting strength. High, high tensile strength, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

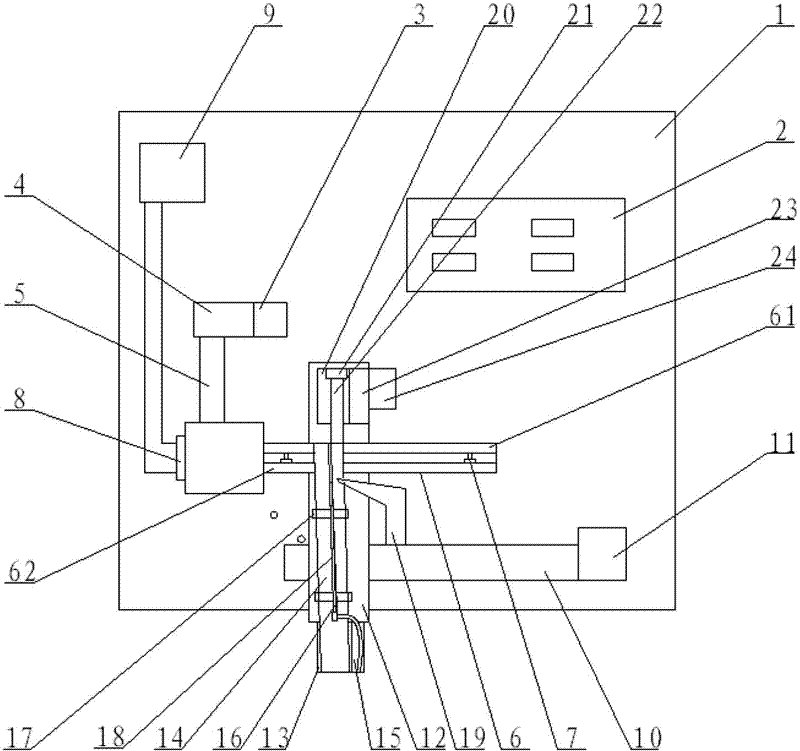

[0025] figure 1The shown non-woven air filter intake pipe winding machine includes an electric control box 2 all arranged on a frame 1, a winding rotating device, a feeding device and a gluing device. The feeding walking device connects the non-woven fabric roll 13 and the nylon filament roll 15, the electric control box 2 controls the rotation of the winding rotating device, and the electric control box controls the feeding walking device to walk along the direction of the winding rotating device and transfer the non-woven fabric strip 14 and the nylon filament 16 Feed into the winding and rotating device to rotate and wind the non-woven strips and nylon filaments from the inside to the outside, and the gluing device synchronously glues the non-woven strips wound on the winding and rotating device; the winding and rotating device includes a rotating motor 3, a rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com