multi-pole connector

A connector and multi-pole technology, applied in the direction of connection, conductive connection, parts of connection devices, etc., can solve the problems of shape change, complicated wiring, labor and time consumption, etc., and achieve high strength, easy assembly, and efficient assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

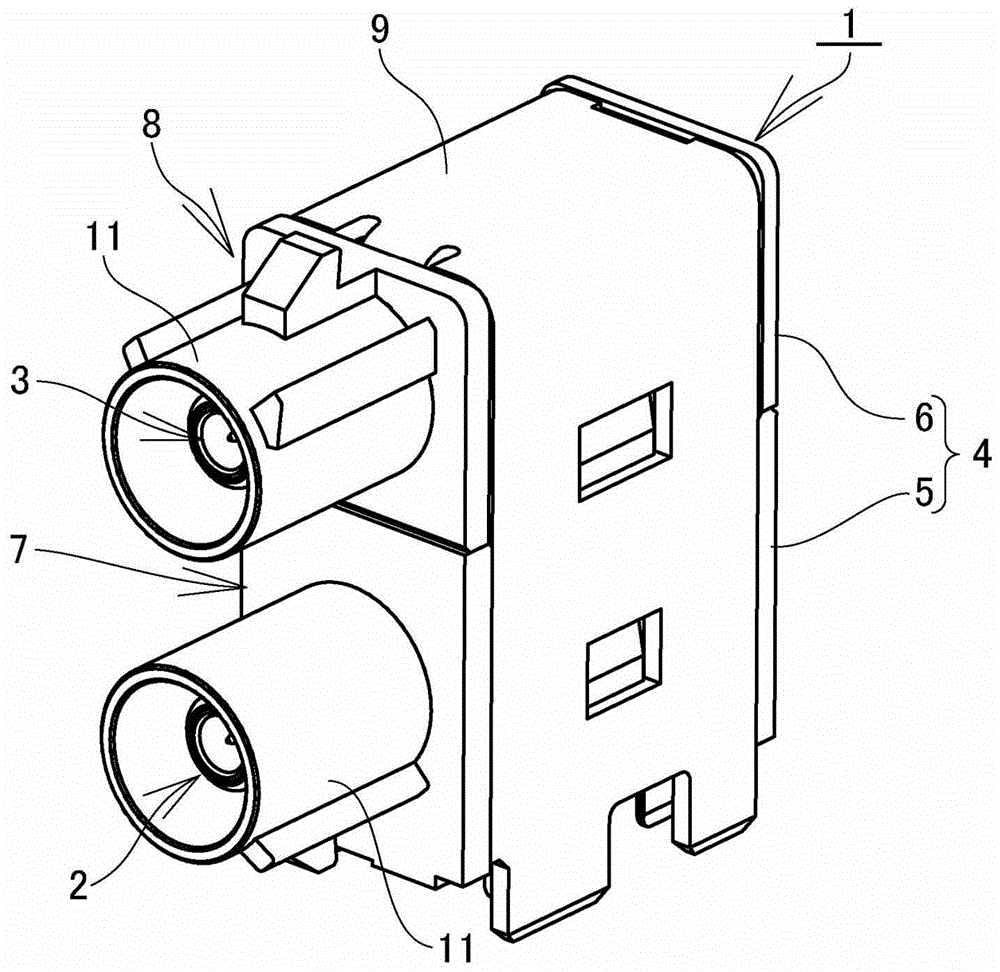

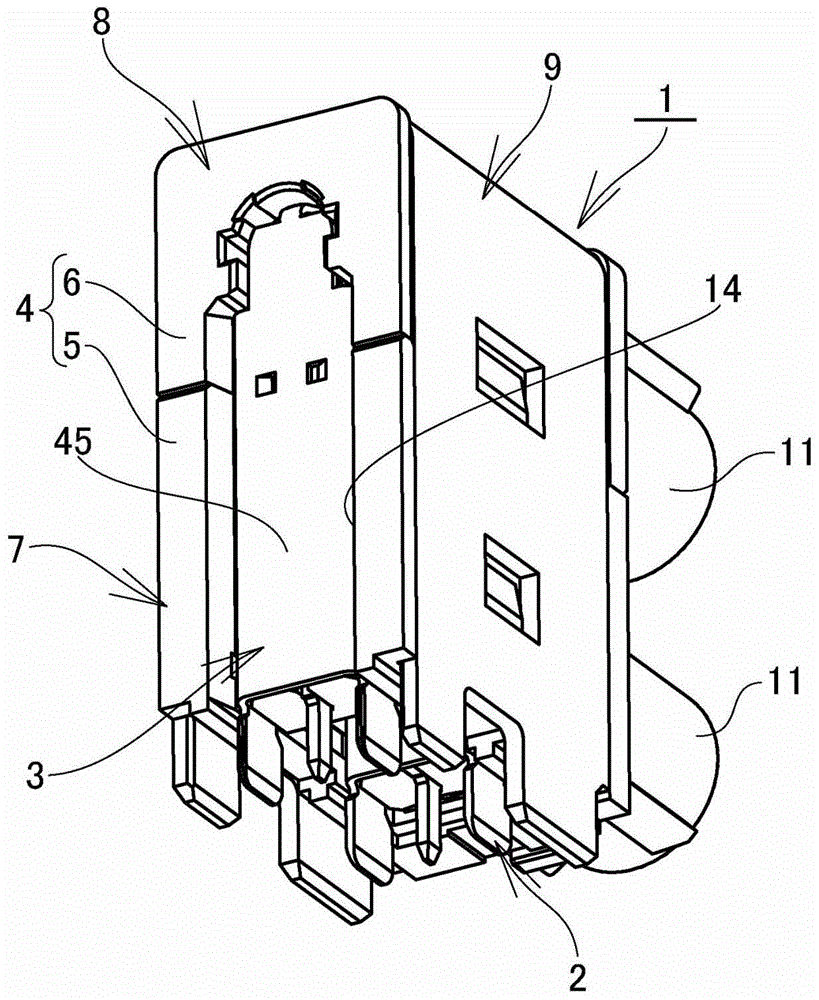

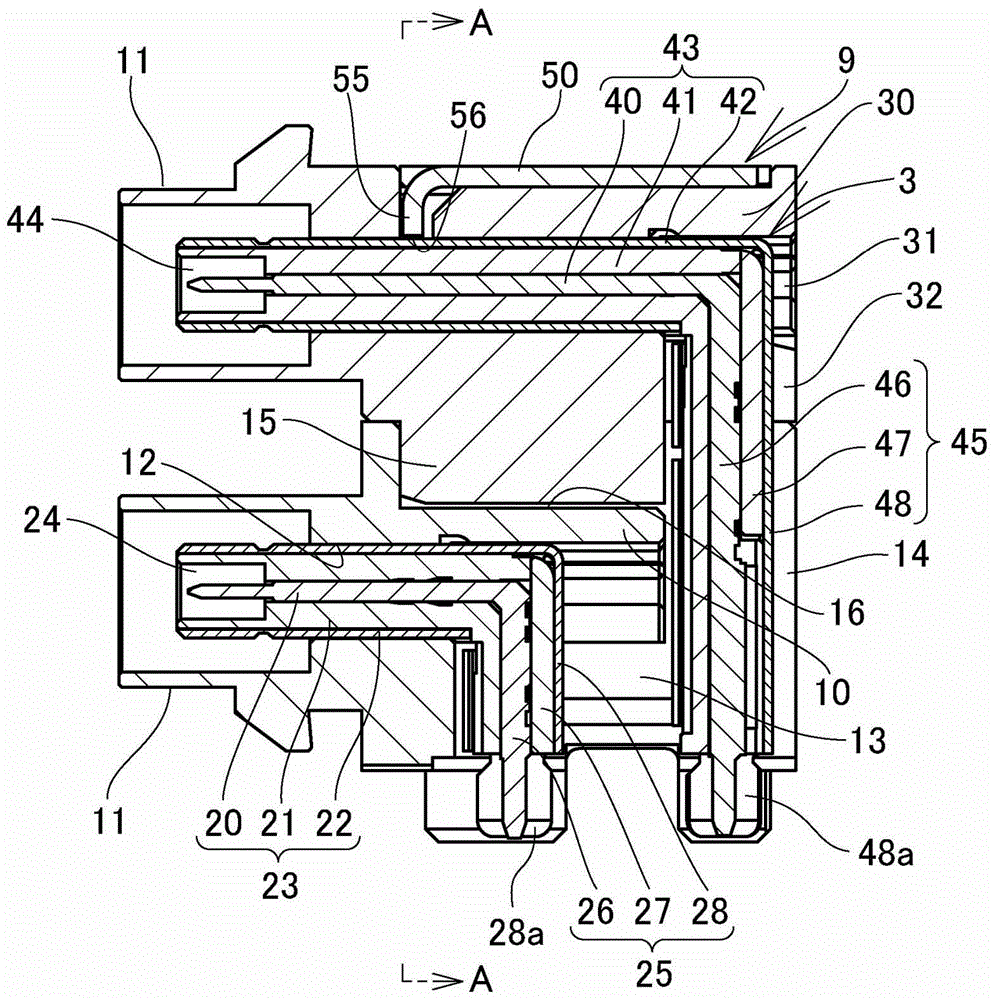

[0052] Next, based on Figure 1 ~ Figure 15 The illustrated embodiment explains the embodiment of the multi-pole connector of the present invention.

[0053] In this embodiment, the bipolar coaxial connector with the upper and lower two layers is taken as an example for description. The symbol 1 in the figure is a multipolar connector.

[0054] In addition, in this embodiment, the vertical direction with respect to the surface of the substrate (hereinafter referred to as the mounting substrate) on which the multipolar connector 1 is mounted is referred to as the vertical direction, and the description is given with the substrate side as the bottom. The connection direction between the surface parallel and the connector 1 and the counterpart connector is called the front-rear direction, and the description will be given with the counterpart side as the front.

[0055] Such as Figure 1 ~ Figure 5 As shown, the multi-pole connector 1 is a multi-pole coaxial connector that is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com