Modular three-body ship

A modular, trimaran technology, applied in the direction of hull, ship construction, hydrodynamic characteristics/hydrostatic characteristics, etc., can solve the problems of restricting the feasibility of land transportation, prevent torsional deformation, increase torsional resistance The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

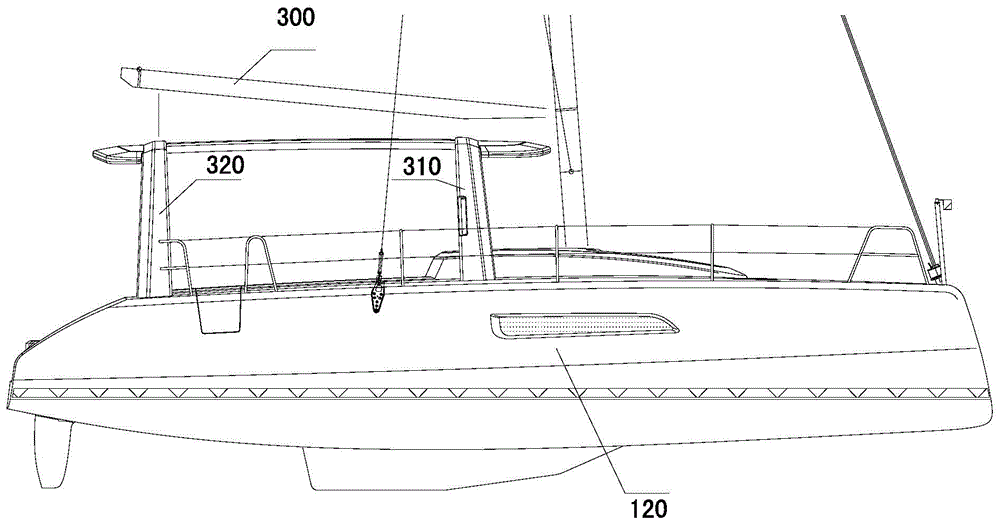

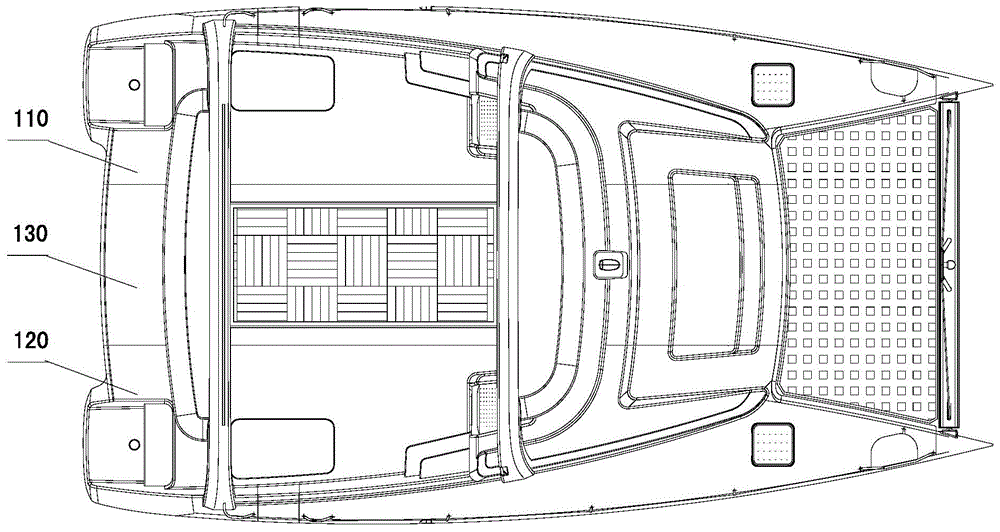

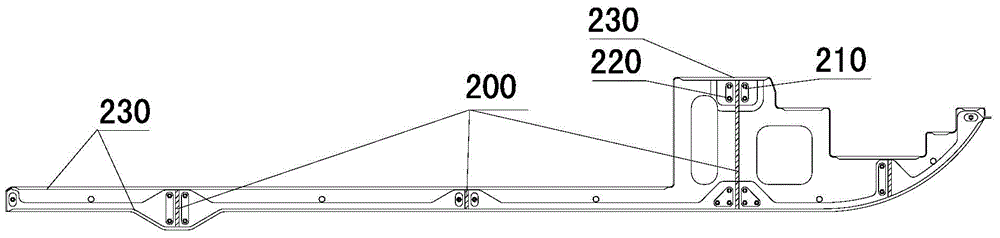

[0037] figure 1 A side view of the hull. figure 2 A top view of the hull. image 3 A cross-sectional view of the hull connection. Such as Figure 1-3 As shown, a modular trimaran, a design of a 36-foot catamaran with a glass-steel structure trimaran hull.

[0038] Such as Figure 1-3 As shown, the hull body is made of three split hulls made of fiberglass composite materials, and the three split hulls are assembled and connected. The split hulls are respectively the left main hull 110 , the right main hull 120 , and the middle deck hull 130 .

[0039] A reinforcing rib 200 is arranged between the left main hull 110 and the middle deck hull 130 , and a hull connector is arranged on the reinforcing rib 200 .

[0040] A reinforcing rib 200 is arranged between the middle deck hull 130 and the right main hull 120 , and a hull connector is arranged on the reinforcing rib 200 .

[0041] Such as Figure 4-5 As shown, the ceiling 300 is arranged above the split hull, the left s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com