Solid electrolytic capacitor and manufacturing method of the same

A technology of solid electrolysis and manufacturing method, applied in the direction of solid electrolytic capacitors, electrolytic capacitors, capacitors, etc., can solve problems such as loss of installability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

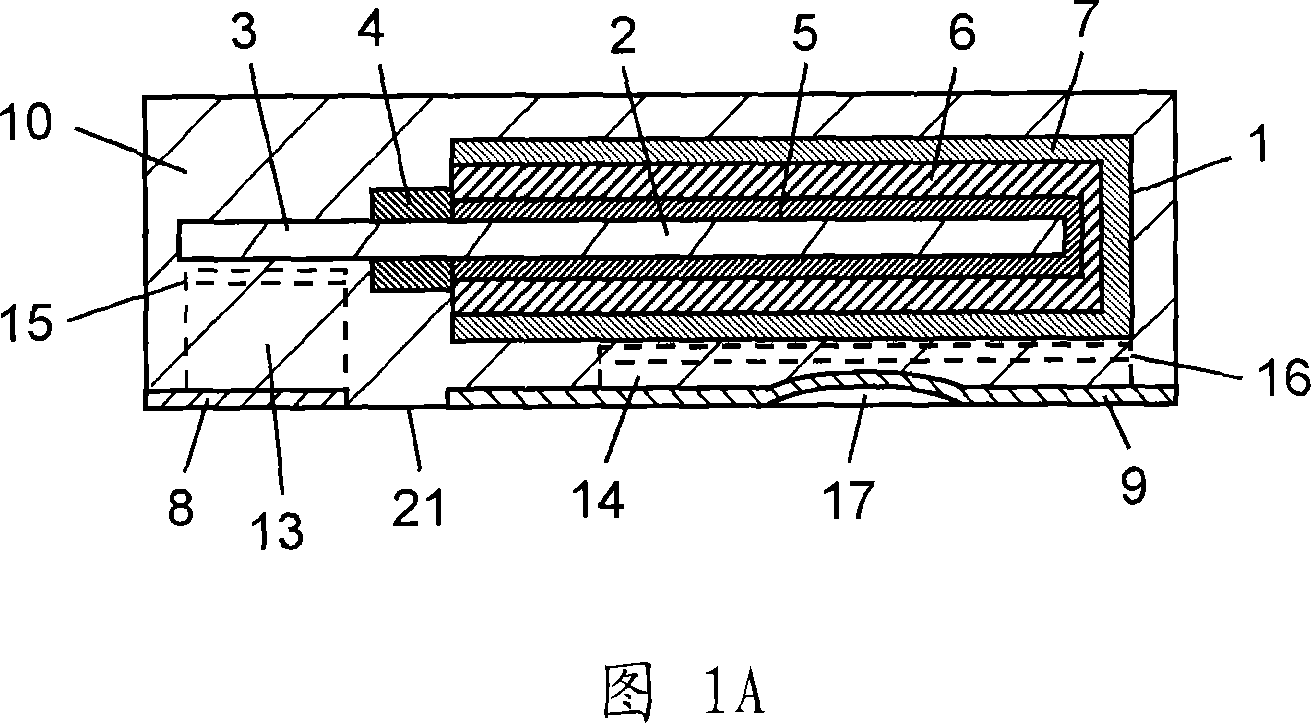

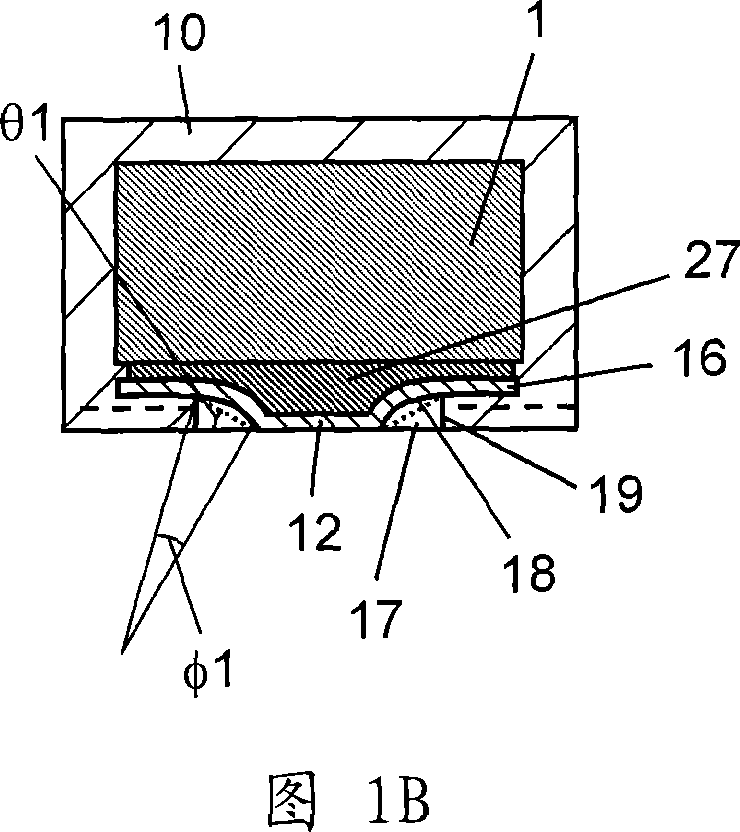

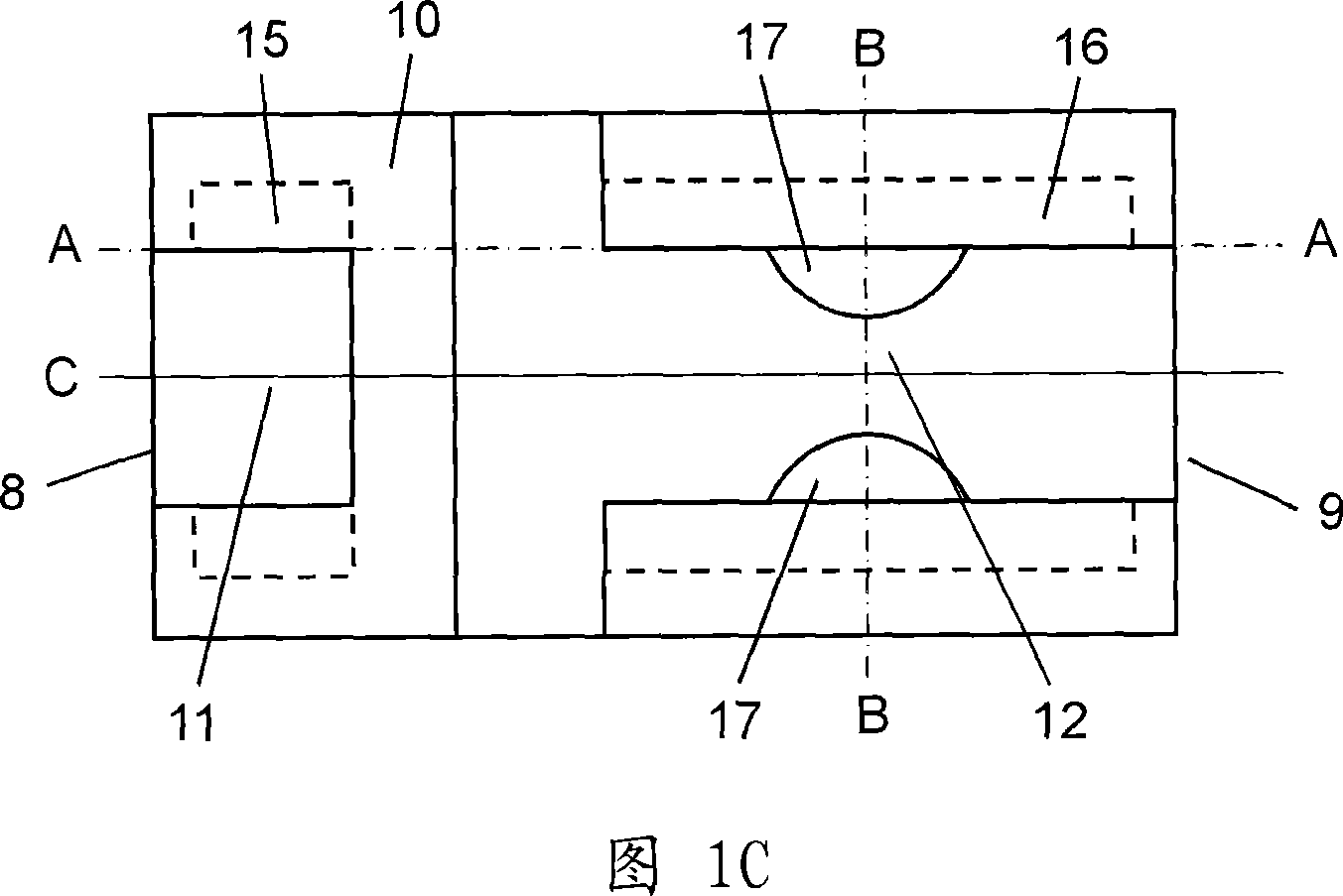

[0026] 1A is a side sectional view of a solid electrolytic capacitor according to an embodiment of the present invention, FIG. 1B is a front sectional view, and FIG. 1C is a bottom view. Wherein, FIG. 1A is a cross-sectional view along line A-A of FIG. 1C , and FIG. 1B is a cross-sectional view along line B-B of FIG. 1C .

[0027] The capacitor element 1 has an anode body 2 , an anode lead-out portion 3 , an insulator layer 4 , a dielectric oxide film 5 , a solid electrolyte 6 , and a cathode layer 7 . The anode body 2 is formed of a valve metal foil. The insulator layer 4 divides the anode body 2 into an anode part and a cathode part. The anode lead-out portion 3 is provided at one end of the anode portion of the anode body 2 , and the dielectric oxide film 5 is formed on the other end surface of the anode body 2 to be the cathode portion. A solid electrolyte 6 made of a conductive polymer is provided on the dielectric oxide film 5 . The cathode layer 7 is laminated on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com