A two-step method for manufacturing pedt cathode chip tantalum electrolytic capacitors

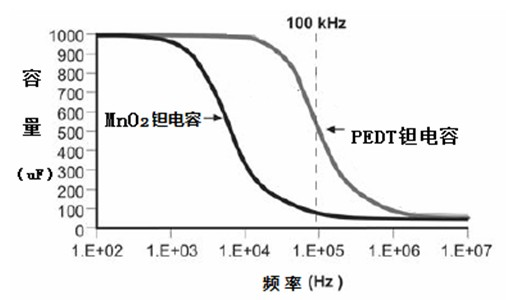

A technology of tantalum electrolytic capacitor and manufacturing method, applied in electrolytic capacitors, capacitors, capacitor electrodes and other directions, can solve the problems of capacitor fire and combustion, high ESR of tantalum capacitors, and achieve the effects of reducing damage, reducing ESR, and improving high-frequency characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

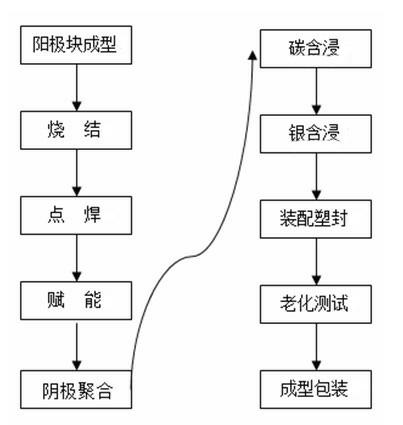

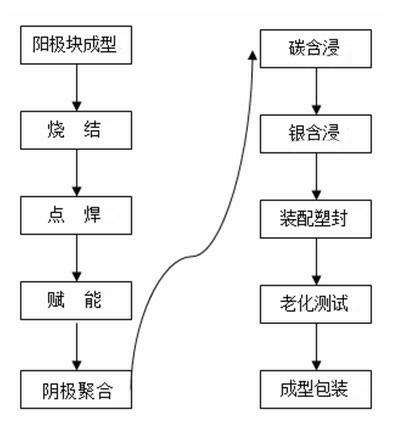

[0062] The valve metal tantalum powder bonded to each other after high-temperature sintering is used as the positive electrode, and a layer of amorphous Ta is formed on the surface by the principle of electrolysis. 2 o 5 As a dielectric, then use the method of the present invention to form a conductive polymer with a certain thickness on the outer layer as the negative electrode, and then encapsulate and mold it.

[0063] This example takes a 10V47μF, C-shell polymer capacitor as an example to explain the manufacturing process in detail:

[0064] 1. Anode formation: Mix tantalum powder with a specific volume of 32000μF.V / g into 2% binder, press 6g / cm 3 Compression molding with the highest pressing density (leaded by φ0.20mm tantalum wire), and sintering at 1400°C for 25-35 minutes in a vacuum sintering furnace.

[0065] 2. Dielectric layer formation: In 2% phosphoric acid solution, adopt 40V DC voltage, 50mA / g current density empowerment, and constant voltage for 3 hours to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com