Manufacturing method of superconductor cavity

A technology of superconducting cavity and superconducting material, which is applied in the manufacturing field of radio frequency superconducting accelerating cavity (referred to as superconducting cavity), which can solve problems such as manufacturing failure, high welding risk, and difficulty in dimensional accuracy of superconducting cavity, and improve the quality of finished products. High frequency and high frequency characteristics, guaranteed high frequency characteristics, and simplified processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

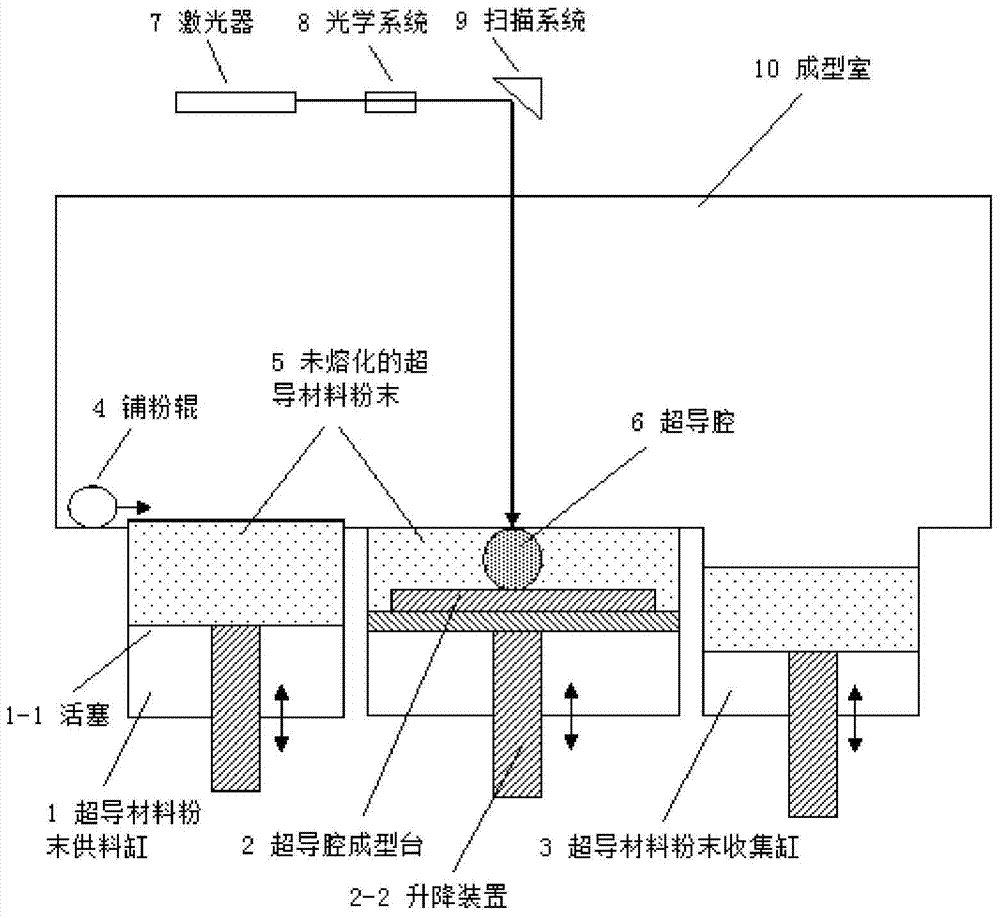

[0035] Example 1: see figure 1 , a method for preparing a high-purity niobium superconducting cavity, which mainly includes the following steps:

[0036] (1) Preparation:

[0037] 1) The raw material is high-purity niobium powder: high-purity niobium powder is obtained by reducing niobium oxide, the particle size of the powder is 10nm-20μm, and the purity is 99%-99.99%;

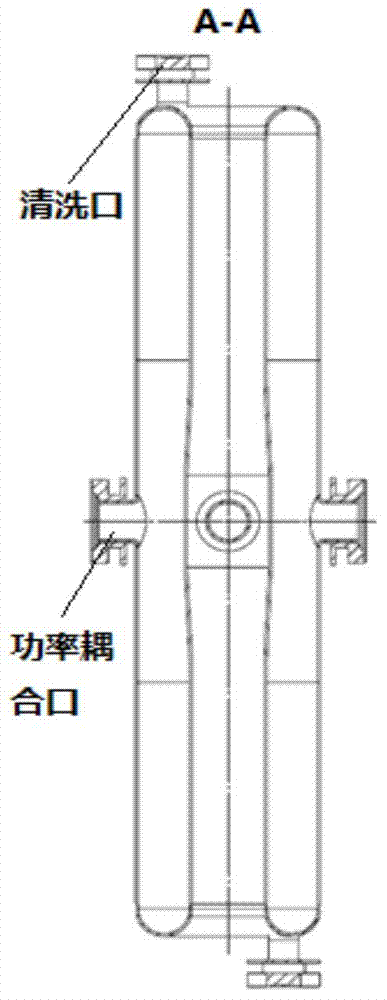

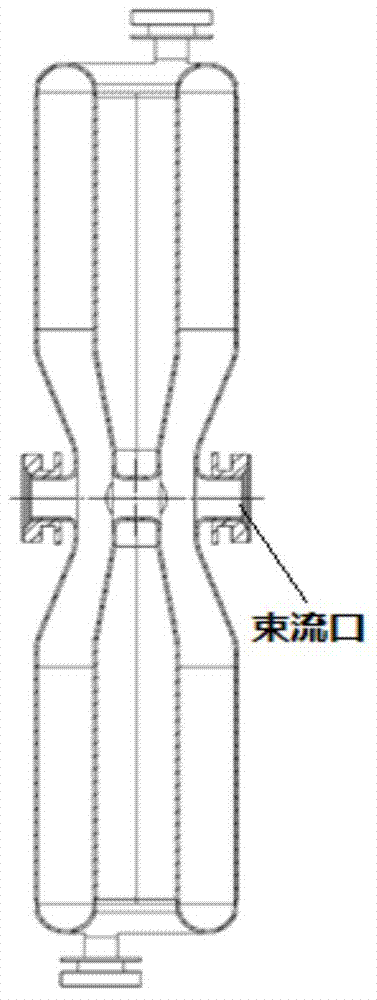

[0038] 2) Use CAD software to generate a superconducting cavity model, taking a half-wavelength cavity as an example, see figure 2 and image 3 , using layering software to layer it, and each slice layer describes the cross-section of the superconducting cavity with a certain height of 0.05-0.3mm;

[0039] 3) Use the atmosphere control system to provide the molding device with argon with a purity better than 99.9996% and a pressure of 0.1-0.2Mpa argon to protect the environment;

[0040] 4) Spread the high-purity niobium powder in step 1) on the working table of the molding room;

[0041] 5) Using the s...

Embodiment 2

[0051] Embodiment 2: Nb proposed by the present invention 3 The embodiment of the Sn superconducting cavity manufacturing method is described in detail as follows:

[0052] 1 preparation:

[0053] (1) The raw material used is Nb 3 Sn powder, powder particle size is 10nm-20μm, purity 99%-99.99%;

[0054] (2) Use CAD and SolidWorks software to draw the superconducting cavity model, taking the half-wavelength cavity as an example, see figure 2 and image 3 , using layering software to layer it, the height of each slice layer is 0.05-0.3mm, and each slice layer describes the cross-section of the superconducting cavity with a certain height;

[0055] (3) For the process of manufacturing superconducting cavity by laser melting, see figure 1 , in the environment protected by high-purity argon, the purity of high-purity argon is 99.9996%, Nb 3 The piston in the Sn powder feeding cylinder 1 moves upwards to supply Nb to the molding chamber 3 Sn powder, powder spreading roller 4...

Embodiment 3

[0062] Embodiment 3: see figure 1 , a MgB 2 A method for preparing a superconducting cavity mainly includes the following steps:

[0063] (1) Preparation:

[0064] 1) The raw material is MgB 2 Powder: powder particle size is 10nm-20μm, purity 99%-99.99%:

[0065] 2) Use CAD software to generate a superconducting cavity model, taking a half-wavelength cavity as an example, see figure 2 and image 3 , using layering software to layer it, and each slice layer describes the cross-section of the superconducting cavity with a certain height of 0.05-0.3mm;

[0066] 3) Use the atmosphere control system to provide the molding room with argon with a purity better than 99.9996% and a pressure of 0.1-0.2Mpa argon to protect the environment;

[0067] 4) Add the MgB from step 1) 2 The powder is spread on the working table of the molding room;

[0068] 5) Use the scanning control system to "print" the laser energy onto the powder layer according to the software model description of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com