New bonding and assembling process for slow wave circuit of microwave tube and its bonding agent cleaning system

A slow-wave circuit and cleaning system technology, which is applied to the circuit components, electrical components, and manufacturing tools of transit-time electronic tubes, can solve problems such as the inability to completely remove adhesives, save cleaning solvents, and improve high-frequency Features, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The new process of bonding and assembling microwave tube slow wave circuit of the present invention has the following steps:

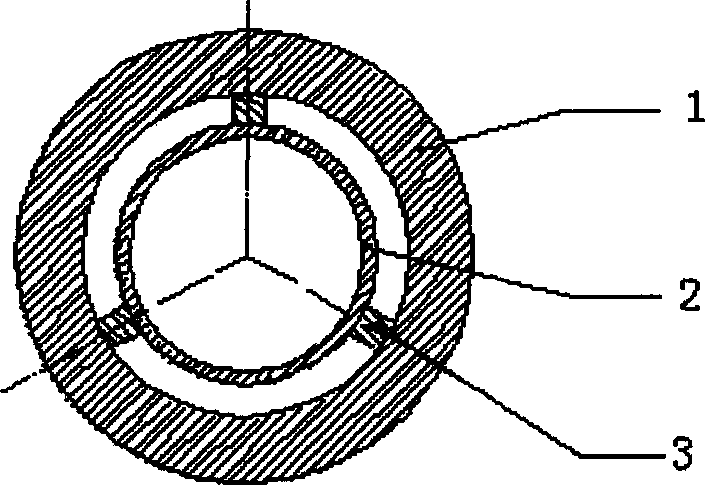

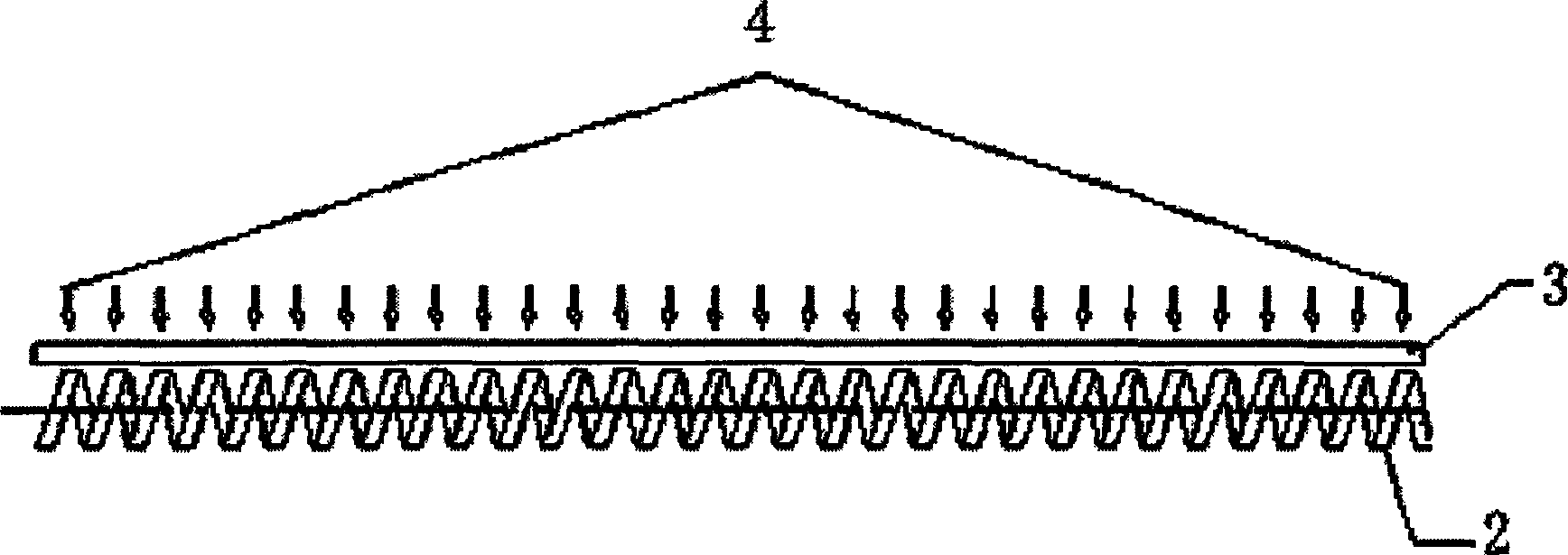

[0035] a) First, accurately position the three clamping rods on the helix with the core rod at an angle of 120 degrees, and then apply adhesive to bond the clamping rod and the helix. Molding agent, the beam is a rectangular inner groove structure with a taper angle, the upper inner groove is an inverted T-shaped groove, the clamping rod is embedded below the taper angle, and then the positioning agent is applied in the groove of the beam, and then the The axis of the core rod is accurately positioned on the axis of the main positioning block. There are two main positioning blocks, which are regular hexagonal structural parts. Six positioning holes are uniformly arranged around each main positioning block. Two main positioning blocks It is fixed by 6 steel rods closely matched with the positioning holes, and the distance between them depends on ...

Embodiment 2

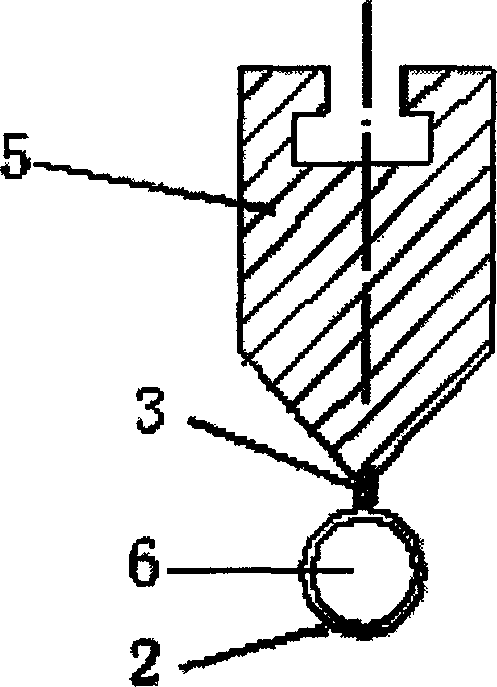

[0049] Method and technology are with embodiment 1, and difference is as follows Figure 8 The cleaning jig 24 shown is placed vertically. When placed vertically, the flow direction of the cleaning liquid is vertically downward, and the washing direction of the liquid is consistent with the direction of gravity, so the washing effect is better. The direction of gravity is consistent. During the flushing process, the inner core may be flushed away from the assembly position, causing flushing to be scrapped; while flushing in the horizontal position, the liquid flushing direction is perpendicular to the direction of gravity, and the flushing effect is worse than that in the vertical position. The scouring force on the inner core component of the microwave tube is perpendicular to the direction of gravity, and it is relatively difficult to wash away from the assembly position. These two methods can be easily switched as needed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com