Edge coupling photoelectric device packaging structure and preparation method thereof

A technology for packaging structure and optoelectronic devices, which is applied to optical components, coupling of optical waveguides, light guides, etc., can solve the problems of unsuitability for mass production of optoelectronic devices, high input cost, low efficiency, etc., and achieves easy assembly process and mass production, Small assembly error and the effect of reducing transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

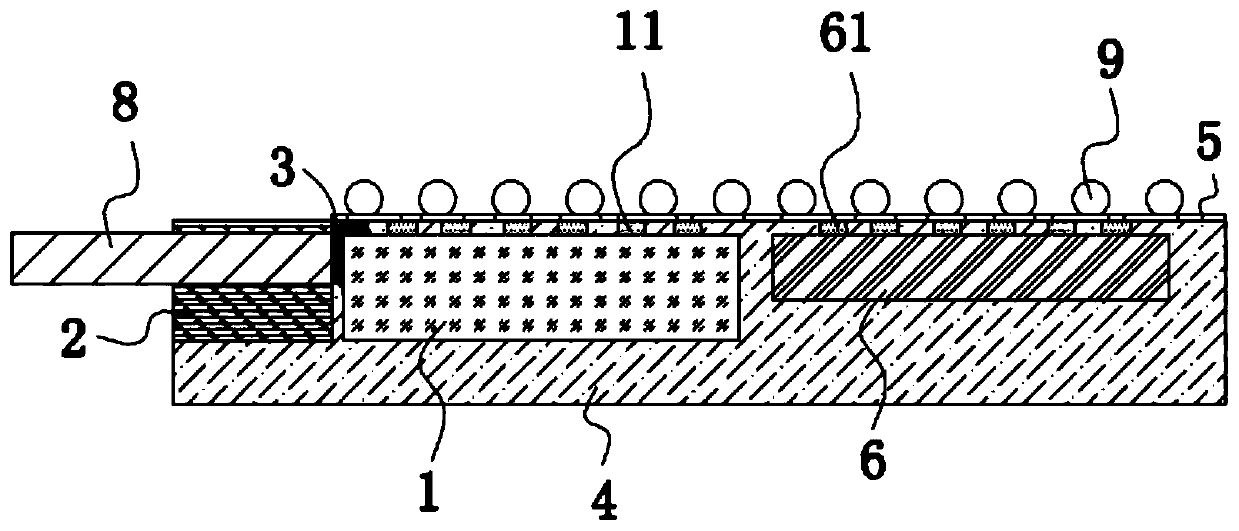

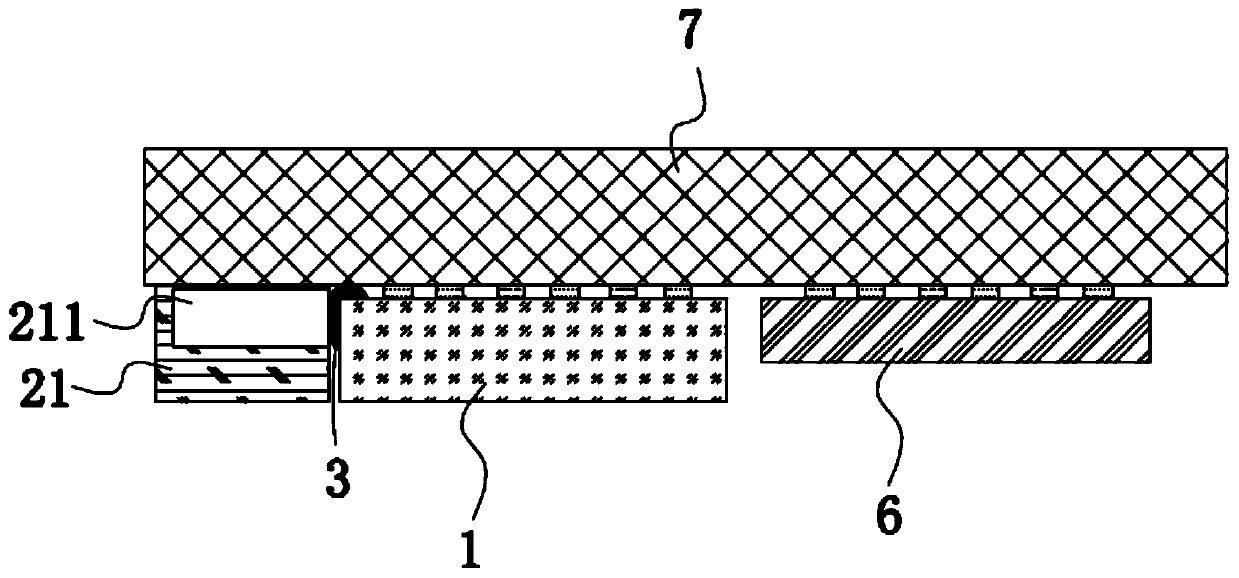

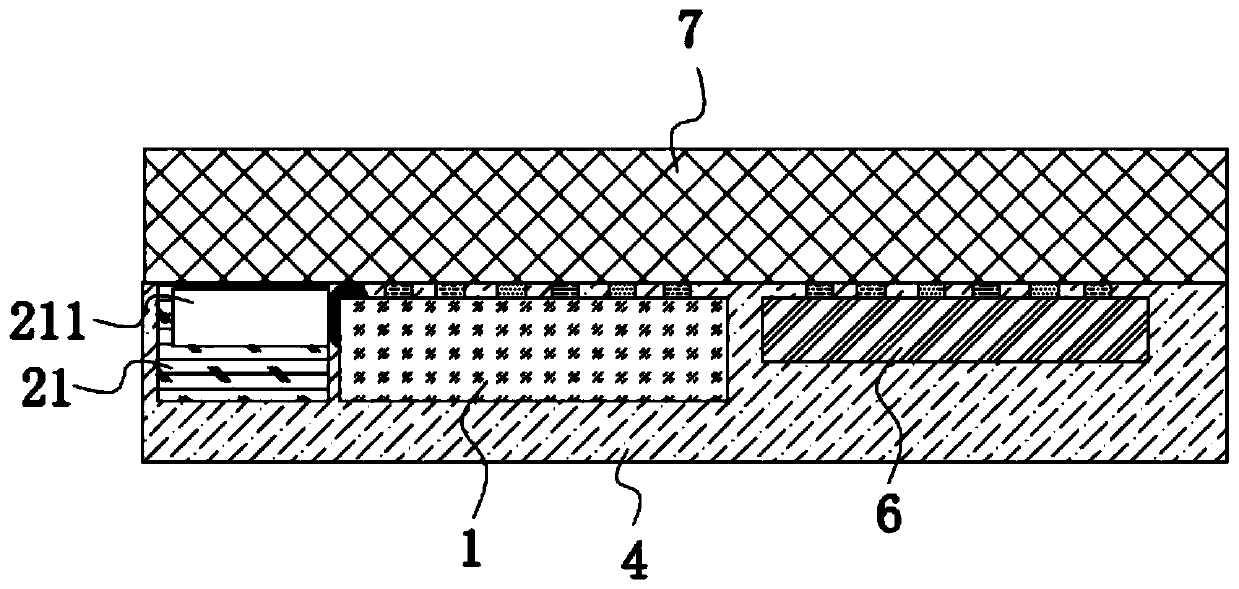

[0044] like figure 1 As shown, this embodiment relates to a packaging structure of an edge-coupled optoelectronic device, including an optical chip 1 , an optical coupling structure block 2 , a transparent resin protection structure block 3 and a packaging layer 4 .

[0045] The optical chip 1, the optical coupling structural block 2 and the transparent resin protective structural block 3 are plastic-sealed together by the encapsulation layer 4, the optical chip 1, the optical coupling structural block 2 and the transparent resin protective structural block 3 are located in the encapsulation layer 4, and the optical coupling structural block 2 is used to fix the optical fiber 8 so that the optical fiber 8 is coupled with the optical chip 1, the transparent resin protective structure block 3 is arranged between the optical chip 1 and the optical coupling structural block 2, and the transparent resin protective structural block 3 is used to protect the coupling of the optical chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com