Coiling method for annular inductor and annular inductor

A technology of toroidal inductance and winding method, applied in transformer/inductor parts, transformer/inductor coil/winding/connection, inductance with magnetic core, etc., can solve the difficult application of differential mode inductance and PFC inductance, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

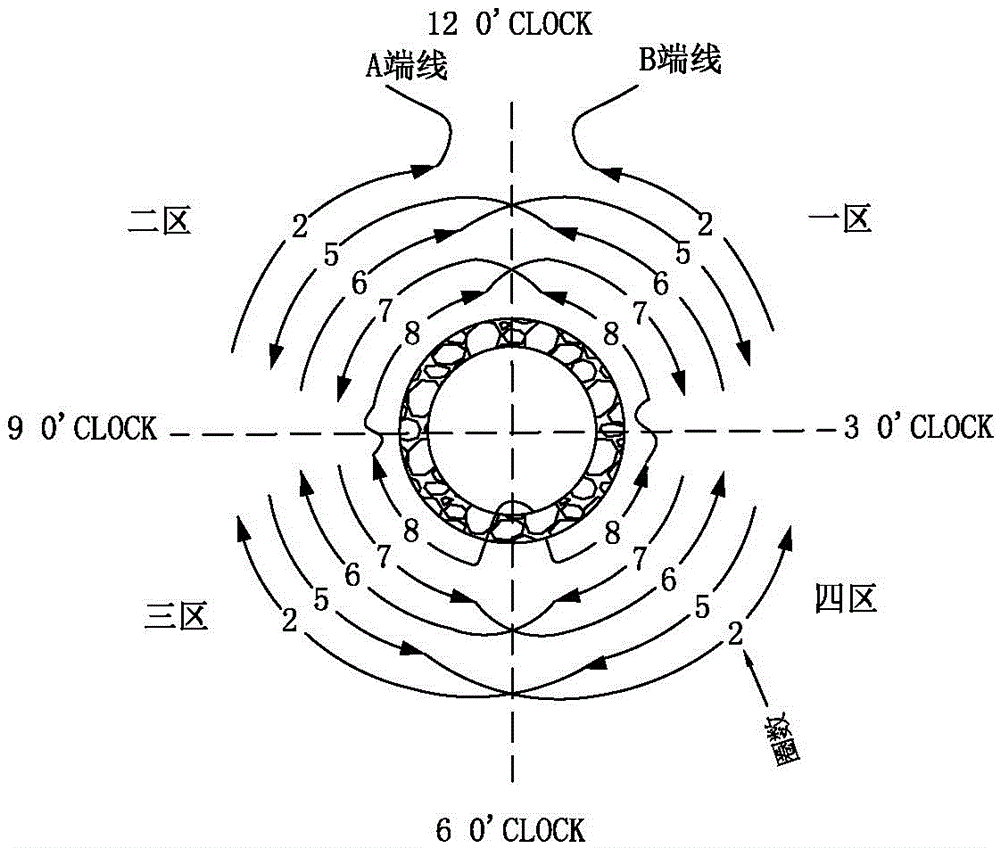

[0030] see figure 1 , the winding method of the toroidal inductor of this embodiment is to divide the toroidal core into four winding areas on average, divide the copper wire into two halves, one end of the copper wire is wound clockwise along the toroidal magnetic core, and the other end of the copper wire The wire is wound along the ring-shaped magnetic core in the counterclockwise direction, and the copper wire is flat and densely wound in the four winding areas to form four copper coil groups, and there are gaps between the copper coil groups in the adjacent winding areas.

[0031] Among them, the half of the copper wire around the ring core is taken as the 6 o'clock direction, one end of the copper wire is used as the A-end wire, and the other end of the copper wire is used as the B-end wire, and the A-end wire of the copper wire passes through the 9 o'clock direction from the 6 o'clock direction. The clock direction is then wound to the direction of 12 o'clock, and the B...

Embodiment 2

[0039] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 1 is that the copper wire is wound in 4 layers on the toroidal magnetic core, and when the first layer of copper wire is wound, each winding area is wound 9 times; the second layer of copper wire is wound When the copper wire is wound on the third layer, each winding area is wound 7 times; when the copper wire is wound on the fourth layer, each winding area is wound 4 times.

Embodiment 3

[0041] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 1 is that the copper wire is wound in one layer on the toroidal magnetic core, and when the copper wire is wound in the first layer, each winding area is wound 10 times.

[0042] Example 3

[0043] The winding of the anti-electromagnetic interference differential mode inductor in this embodiment is wound using the winding method of the ring inductor in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com