Method for manufacturing tinned winding wire

A manufacturing method and winding wire technology, applied in cable/conductor manufacturing, plastic/resin/wax insulators, organic insulators, etc., can solve problems that cannot meet safety, reliability, and stability, and reduce leakage inductance and distributed capacitance , Improve high-frequency characteristics and anti-interference, and reduce processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0010] A manufacturing method of tin-plated winding wire, the method adopts a Φ3mm copper rod to be thinned to Φ0.20-1.00mm by a wire drawing machine, then anneals and tin-plates to obtain a tin-plated copper conductor, and then passes through a 30-type three-head extruder in sequence Two layers of polyphenylene sulfide insulating layers are extruded on the outside of the tinned copper conductor, and then polyamide resin insulating layers are extruded on the outside of the two layers of polyphenylene sulfide insulating layers.

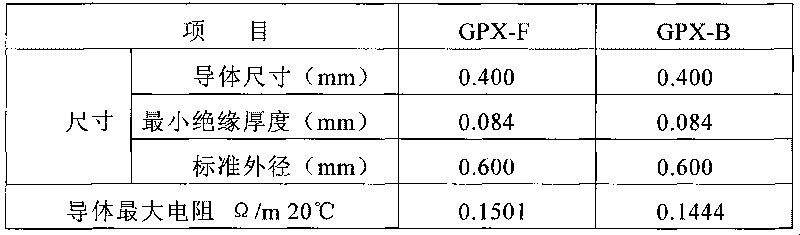

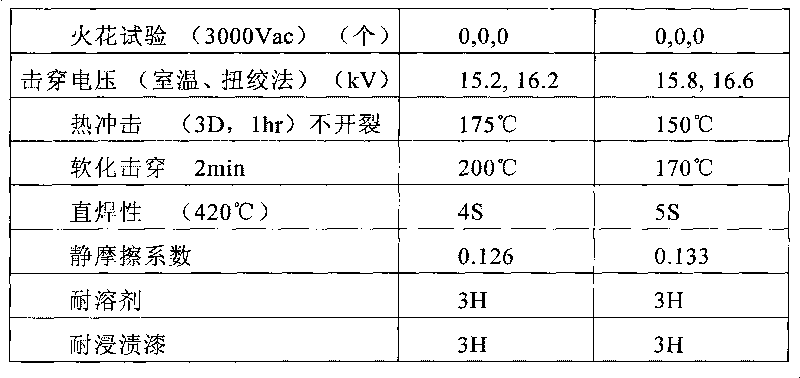

[0011] The performance of the tinned winding wire obtained by the above method is:

[0012] (1) Production specification range: 0.20~1.00mm;

[0013] (2) Temperature resistance class F (155°C);

[0014] (3) Since the electronic structure of Sn is arranged as (2, 8, 18, 18, 4), there are 4 electrons in the outermost shell, and the electronic structure of Cu is (2, 8, 18, 1), and there is 1 electron in the outermost shell. Therefore, tinned copper cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com