Laser array beam combining device

A laser array and laser beam technology, applied in the field of lasers, can solve the problems of long adjustment difficulty, inconvenient expansion of semiconductor laser power, and high stability requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

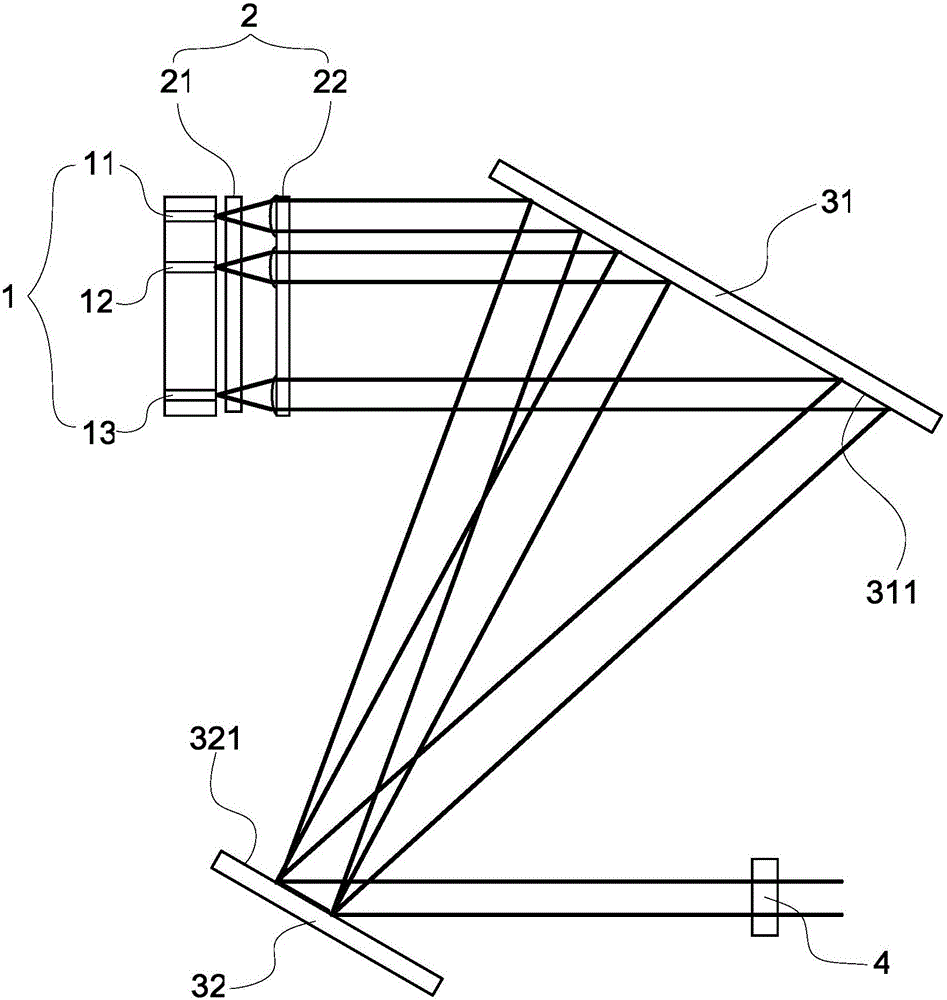

[0034] See figure 1 , Which shows a schematic structural diagram of the laser array beam combining device of the first embodiment of the present invention. in figure 1 In the preferred embodiment shown, the laser array beam combining device includes: a laser gain medium array 1, a shaping optical system 2, a dispersive optical component, and a partially reflective optical element 4.

[0035] The laser gain medium array 1 includes at least two laser gain elements, each of which can generate a laser beam with a certain spectral width. in figure 1 In the illustrated embodiment, the laser gain medium array 1 is preferably a semiconductor laser array. The laser gain medium array 1 includes multiple laser gain elements. It should be noted that, figure 1 Only the first laser gain element 11, the second laser gain element 12, and the third laser gain element 13 are schematically shown in, where the third laser gain element 13 is n laser gain elements spaced from the second laser gain ele...

no. 2 example

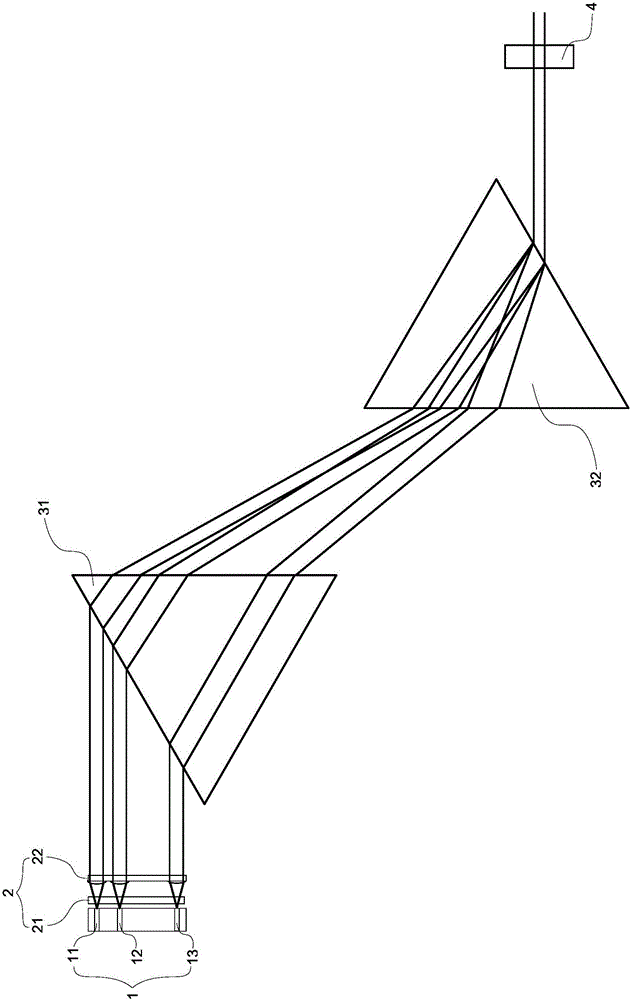

[0041] See figure 2 , Which shows a schematic structural diagram of the laser array beam combining device of the second embodiment of the present invention. With the above figure 1 The difference in the first embodiment shown is that in this embodiment, the first dispersive optical element and the second dispersive optical element are a pair of diffraction gratings. The first dispersive optical element and the second dispersive optical element use a pair of diffraction gratings instead of the prism pair in the above-mentioned first embodiment. Specifically, such as figure 2 As shown, the first dispersive optical element 31' and the second dispersive optical element 32' are a pair of diffraction gratings. The diffraction grating may be a transmissive grating or a reflective grating. Preferably, the grating surfaces of the pair of diffraction gratings are parallel to each other and have the same grating period. This embodiment can achieve similar effects to the above-mentione...

no. 3 example

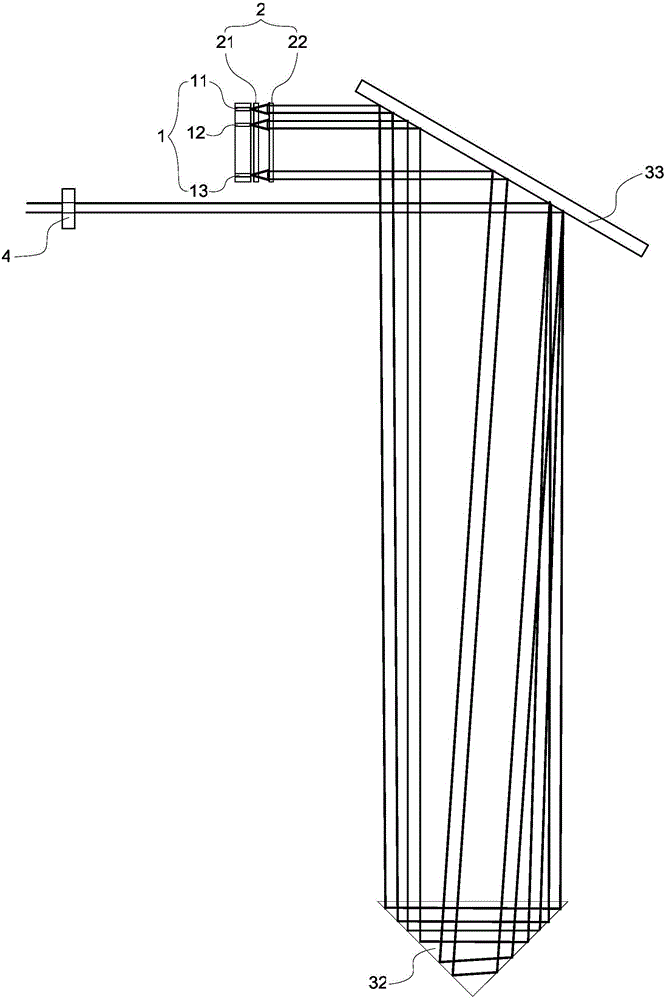

[0043] See image 3 , Which shows a schematic structural diagram of a laser array beam combining device according to a third embodiment of the present invention. With the above figure 1 with figure 2 The difference between the first embodiment and the second embodiment shown is that in this embodiment, the dispersive optical component includes a third dispersive optical element and a reflective prism. The dispersive optical component uses the third dispersive optical element and the reflective prism to replace the above-mentioned first dispersive optical element and the second dispersive optical element. Specifically, such as image 3 As shown, the dispersive optical component includes a third dispersive optical element 33 and a reflective prism 34. The third dispersive optical element 33 diffracts or refracts the collimated laser beam array incident by the shaping optical system 2. in image 3 In the illustrated embodiment, the third dispersive optical element 33 is a dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com