Rust-proof metal door plank fastener

A technology for fasteners and door panels, which is applied in the field of antirust fasteners for metal door panels. It can solve problems such as the inability to disassemble bolts and nuts, affect the appearance, and lack of fastening effects, etc., to overcome easy oxidation and corrosion, improve small structures, and design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

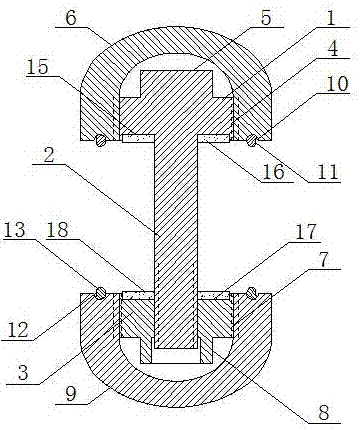

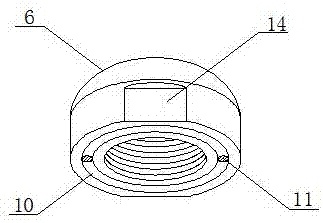

[0014] An antirust fastener for a metal door panel of the present invention comprises a screw head 1, a screw rod 2 and a nut 3, the screw head 1 is a cylinder, and the outer circumference is provided with thread I4, and the inner end of the screw head 1 is fixedly connected with one end of the screw rod 2 The other end of the screw 2 is used in conjunction with the screw port of the nut 3. The outer end of the screw head 1 is provided with an outer hexagonal protrusion 5, and the outer end of the screw head 1 is connected to the cap body I6 through the thread I4. The nut 3 is a cylinder with threads on the outer periphery. Ⅱ7, the outer end of the nut 3 is provided with an external hexagonal extension 8, the nut 3 is connected to the cap body Ⅱ9 through the thread Ⅱ7, the inner edge of the cap body Ⅰ6 is provided with a groove Ⅰ10, and the groove Ⅰ10 is provided with an apron Ⅰ11, the cap body A groove II12 is arranged on the inner edge of II9, and an apron II13 is arranged in...

Embodiment 2

[0016] An antirust fastener for a metal door panel of the present invention comprises a screw head 1, a screw rod 2 and a nut 3, the screw head 1 is a cylinder, and the outer circumference is provided with thread I4, and the inner end of the screw head 1 is fixedly connected with one end of the screw rod 2 The other end of the screw 2 is used in conjunction with the screw port of the nut 3. The outer end of the screw head 1 is provided with an outer hexagonal protrusion 5, and the outer end of the screw head 1 is connected to the cap body I6 through the thread I4. The nut 3 is a cylinder with threads on the outer periphery. Ⅱ7, the outer end of the nut 3 is provided with an external hexagonal extension 8, the nut 3 is connected to the cap body Ⅱ9 through the thread Ⅱ7, the inner edge of the cap body Ⅰ6 is provided with a groove Ⅰ10, and the groove Ⅰ10 is provided with an apron Ⅰ11, the cap body A groove II12 is arranged on the inner edge of II9, and an apron II13 is arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com