Transverse laminated connection type single compartment precast multiple-compartment assembled comprehensive pipe gallery

An integrated pipe gallery and connected technology, which is applied in the field of horizontally superimposed and connected single-cabin prefabricated multi-cabin assembled integrated pipe gallery, can solve the problems of material consumption such as formwork and on-site support, low energy saving and environmental protection benefits, and long on-site construction period. , to achieve the effect of good integrity and waterproof and anti-seepage performance, speeding up the overall construction speed, and high comprehensive economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is further illustrated below by means of embodiments in conjunction with the accompanying drawings.

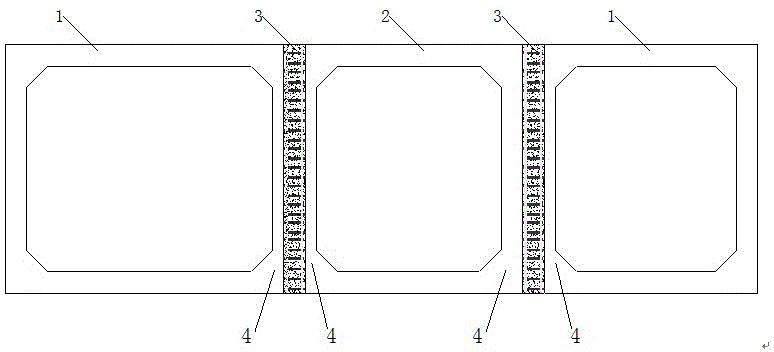

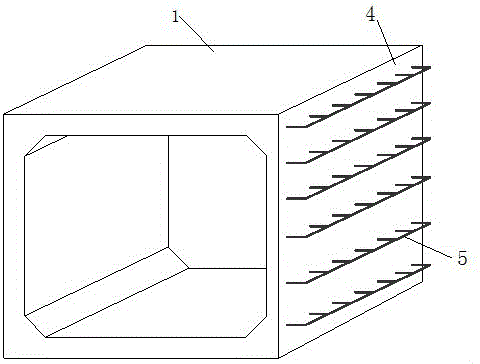

[0015] Embodiment 1, the side-span precast concrete cabin body 1 and the mid-span precast concrete cabin body 2 are all prefabricated in the concrete precast component factory, and their shapes and sizes are determined according to the actual conditions of each project and considering the technical parameters of transportation and hoisting equipment , the quality control shall be carried out in accordance with the current prefabricated component quality control regulations.

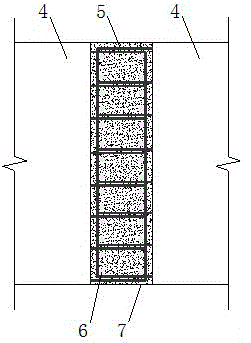

[0016] In this embodiment, the laterally adjacent prefabricated concrete cabins of the integrated pipe gallery form a reliable connection in the lateral direction through the superimposed side walls 3 . Wherein, the laminated side wall 3 is composed of adjacent cabin body connecting side walls 4 and its pre-embedded stirrups 5 , inserting bars 6 and concrete layer 7 .

[0017...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com