Photo-curable resin composition for repairing facing marble plank and preparation and using method of photo-curable resin composition

A light-curing resin and marble plate technology, applied in the direction of modified epoxy resin adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve yellowing resistance, poor aging resistance, volatile matter Escape affects the environment, affects production efficiency and other issues, and achieves the effects of fast curing speed, high gloss of the processed surface, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In a 500ml three-neck glass flask with stirring and reflux condenser, add 188g of epoxy resin E-54 and 75g of vinyl cyclohexene diepoxide ERL-4205, turn on the stirrer, fill with nitrogen, and raise the temperature to 90°C. Put 129.6g of acrylic acid dissolved with 0.5g of triphenylphosphine and 1.0g of p-methoxyphenol into the feeding bottle, drop evenly into the flask, control the temperature at 90-95°C, drop it in 1.5 hours, raise the temperature to 115°C, and 115°C-118°C constant temperature reaction for 4 hours, the steam in the bottle is refluxed through the condenser to continue the reaction. From the beginning of adding acrylic acid, take the material every hour to measure the acid value. After the reaction, the product in the cooling bottle was cooled, and when the temperature dropped to 40° C., it was discharged and nitrogen filling was stopped to obtain 392 g of product. The viscosity, hue and acid value of the product epoxy acrylate resin were analyzed by sa...

Embodiment 2

[0037]When preparing epoxy acrylate resin, the raw materials used are bisphenol F type epoxy resin YDF-175, epoxy equivalent 170, viscosity 2200mpa.s at 25°C, 170g, vinyl ring ethylene diepoxide ERL-4205 75g , catalyst triethylamine 1.0g, polymerization inhibitor ST-1 0.8g acrylic acid 129.6g, operating conditions are the same as embodiment 1, obtain epoxy acrylate resin 372.5g, sampling analysis results are shown in Table 1.

[0038] In the preparation of photocurable resin composition, used raw material is:

[0039] Prepared epoxy acrylate resin 140g, polyester acrylate GF-3106 20g, reactive diluent tert-amyl alcohol triacrylate 24g, acrylate isodecyl 11g, plasticizer polyether 10g, photoinitiator bis 2,6 - 0.8 g of difluoro-3-pyrrole phenyl titanocene (GR-FMT, 784), no filler was added, and the rest was the same as in Example 2 to obtain 204 g of a photocurable resin composition.

[0040] The composition and its sample after 20 minutes of sunlight irradiation, the test re...

Embodiment 3

[0042] When preparing epoxy acrylate resin, the raw materials used are bisphenol A epoxy resin E-54 188 g, diisoprene diepoxide (ERL-4269) 85 g, catalyst triphenylphosphine 0.8 g, di Ethylamine 1.0g, methacrylic acid 153g, other conditions are the same as embodiment 1, get epoxy acrylate resin 426g, sampling test, the results are shown in Table 1.

[0043] When preparing the photocurable resin composition of the present invention, the epoxy acrylate resin consumption is 172g, reactive diluent 1,4-butanediol diacrylate 20g, benzyl acrylate 10g, plasticizer dioctyl phthalate 15g of ester, 3g of photocuring agent KIP 150, no filler, and other conditions were the same as in Example 1, and 204g of photocurable resin composition was obtained. The resin composition and samples were sampled and tested, and the results are shown in Table 2.

[0044]

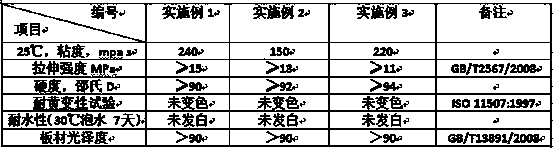

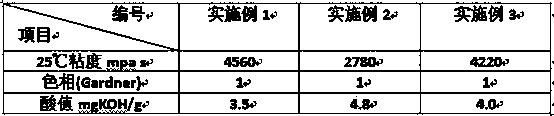

[0045] Table 1 Test results of epoxy acrylate

[0046]

[0047] Table 2 Photocurable resin composition and test results of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com