An assembled overhead leveling floor heating module and its production method and installation method

A prefabricated, flat ground technology, applied in the direction of floor, covering/lining, building, etc., can solve the problems of increasing building load, wasting space operation, long construction period, etc., to improve thermal conductivity and temperature uniformity, and improve laying effect , Improve the effect of multi-performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

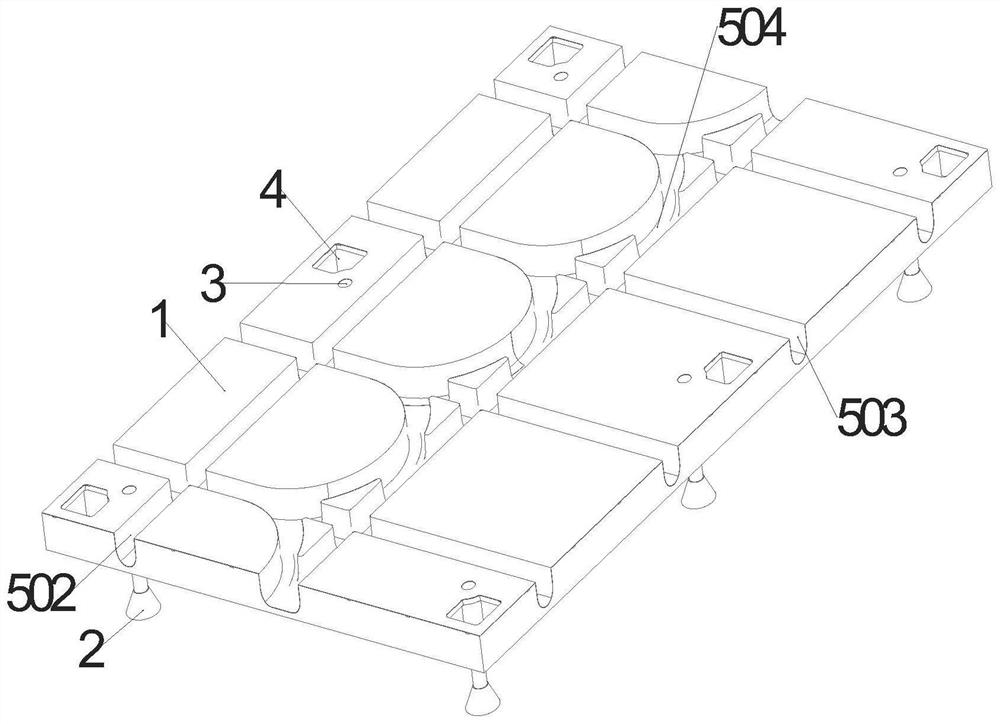

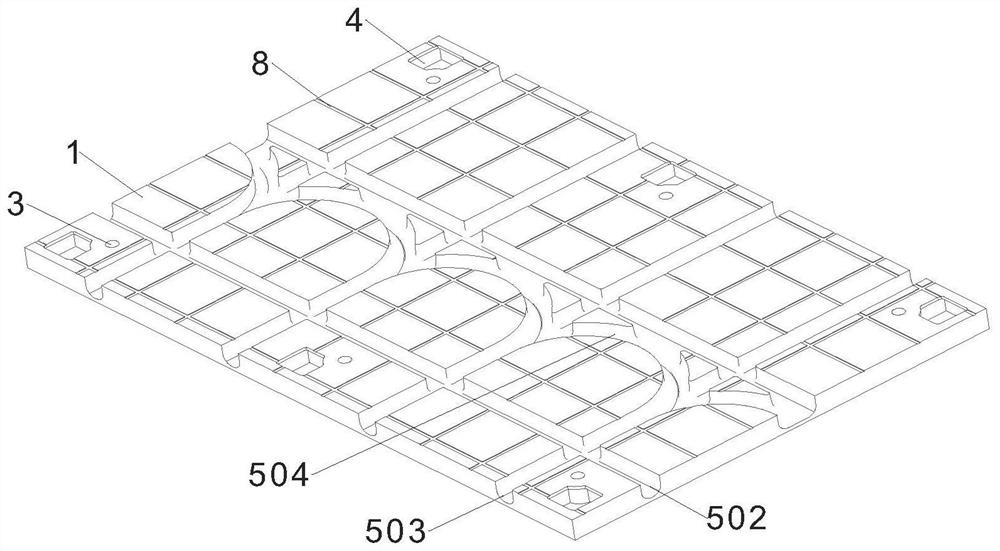

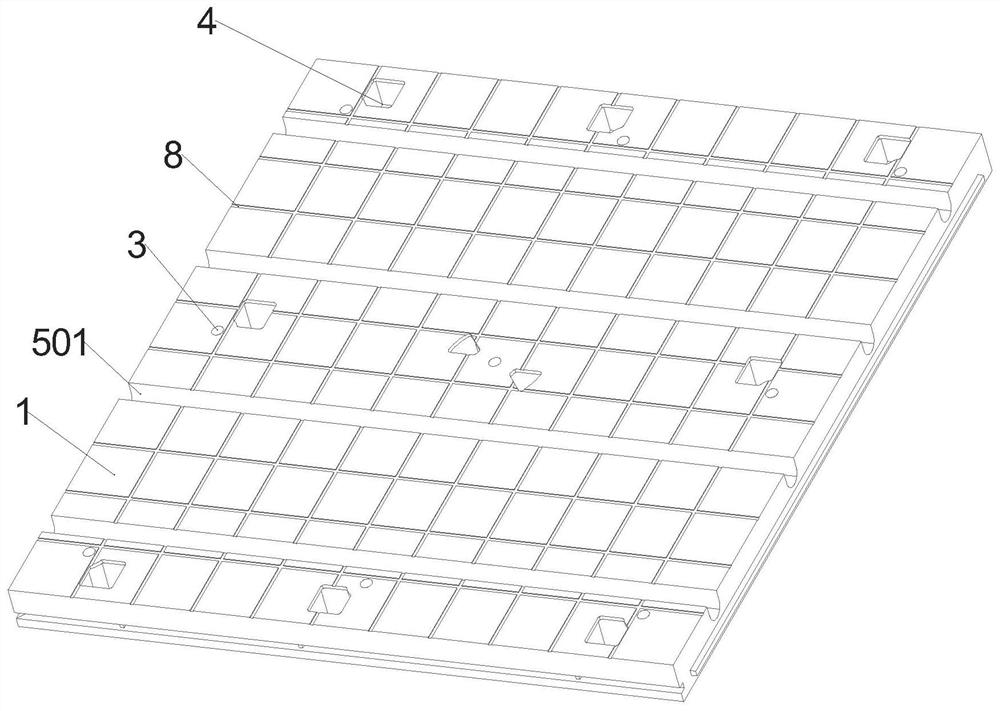

[0066] Please refer to Figure 1-12 , this embodiment provides an assembled overhead leveling floor heating module, including a load-bearing pavement panel 1 and an adjustable support assembly 2;

[0067] The load-bearing pavement panel 1 consists of a nano-carbon crystal layer 101, a reflective heat-conducting layer 102 and a base layer 103 from top to bottom. The nano-carbon crystal layer 101 is sprayed on the surface of the reflective heat-conducting layer 102, and the reflective heat-conducting layer 102 is matched and pressed on the base layer 103 surfaces;

[0068] The side of the load-bearing pavement panel 1 is provided with a splicing mechanism. In this embodiment, the splicing mechanism is a mortise and tenon structure with mutually matching shapes arranged along the diagonal sides of the load-bearing pavement panel 1. One side of the load-bearing pavement panel is provided with a first male The tongue 104 and the second female tongue groove 105 are matched with the...

Embodiment 2

[0085] The present embodiment provides a method for preparing the base layer of the load-bearing pavement panel as in embodiment 1, comprising the following steps:

[0086] Prepare the following component raw materials by weight:

[0087] a. Prepare the following component raw materials by weight: 20-30 parts of alkali-free glass fiber, 11-15 parts of calcium powder, 5-10 parts of aluminum hydroxide, 1-3 parts of lanthanum oxide, 2-3 parts of processing aid, 60-70 parts of phenolic modified PPA resin, 15-20 parts of quartz fiber twill fabric, 1.5-2.5 parts of silane coupling agent, 1-2 parts of hydroxyquinoline aluminum, 40-50 parts of bisphenol A cyanate, 1-2 parts of toughening agent, 10-12 parts of epoxy resin, 6-8 parts of polyphenol oxygen resin;

[0088] The phenolic modified PPA resin is composed of m-diethynylbenzene and p-diethynylbenzene ablation phenolic formaldehyde according to the weight ratio of 4:1;

[0089] Described toughening agent is to take n-butyl acryl...

Embodiment 3

[0096] This embodiment provides a method for installing the assembled overhead leveling floor heating module as in Embodiment 1, including the following steps:

[0097] a. Clean up the concrete floor sanitation, remove dust, and spray ground solid paint;

[0098] b. Measure the size of the house area, match the load-bearing pavement panels and the type and quantity of adjustable support components according to different areas, and match the straight groove load-bearing pavement panels in the load-bearing pavement panels according to the laying shape of the floor heating pipeline and the number of reversible load-bearing pavement panels;

[0099] c. Put horizontal lines. On both sides of the front and rear directions of the installation sequence, place a parallel horizontal line according to the preset overhead height, draw a sliding horizontal line between the two parallel lines, and slide in the direction of non-installation according to the advancement of the installation. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com