A prefabricated overhead leveling ground and its production method and installation method

A prefabricated, ground-based technology, applied in the direction of floors, covering/lining, buildings, etc., can solve the problems of bursting, complicated and troublesome assembly, and increase the load of the building, so as to reduce the generation of air bulges, and the adjustment structure is simple and easy to implement. Improve the effect of multi-function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

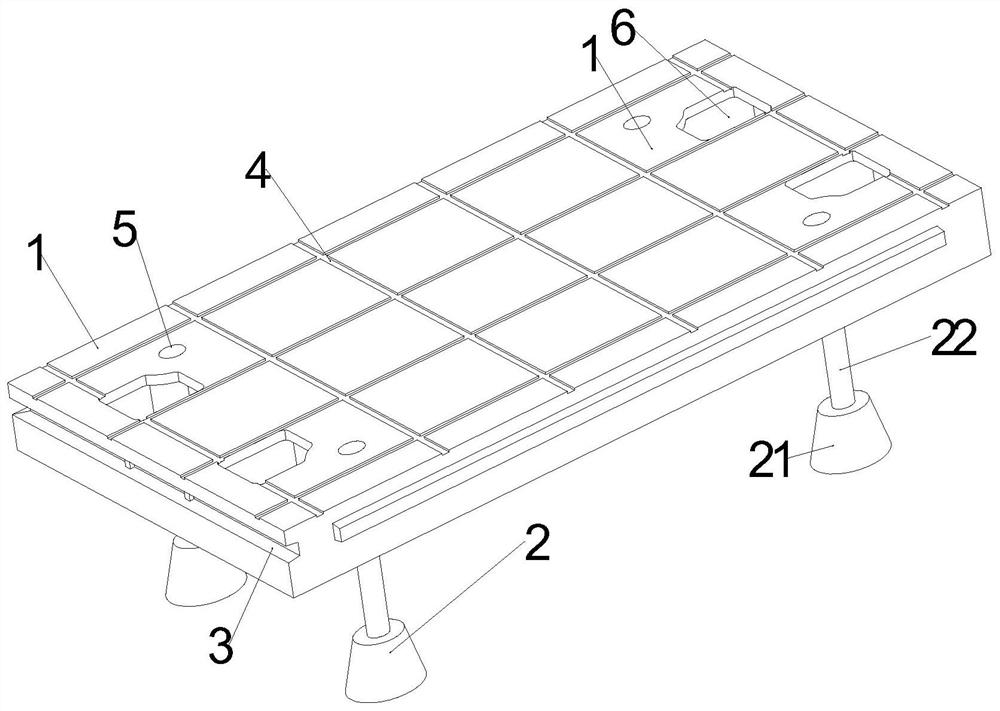

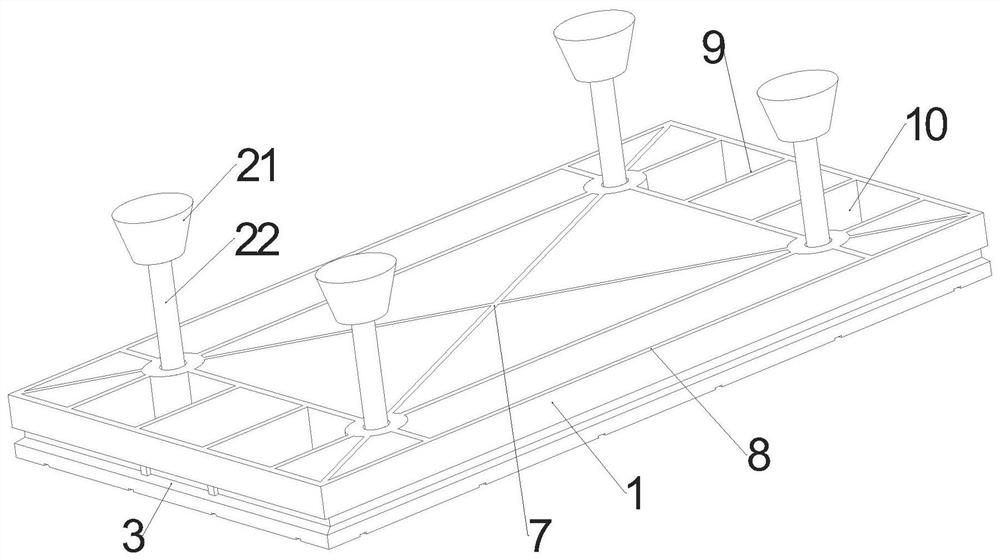

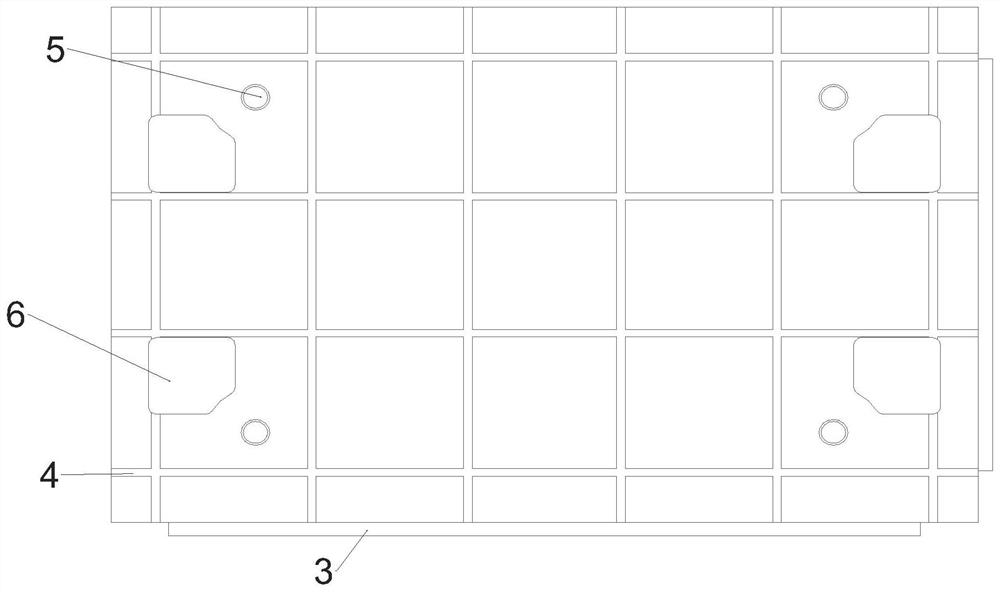

[0052] Please refer to Figure 1-8 , this embodiment provides an assembled elevated leveling ground, including a block load-bearing panel 1 and an adjustable support assembly 2;

[0053] The side of the block-shaped load-bearing panel 1 is provided with a mortise and tenon structure 3 for splicing, and its upper surface is provided with an exhaust guide groove 4 penetrating the surface. The inner wall of the through hole 5 is provided with threads, and the through hole 5 is adjacently provided with a penetrating glue injection port 6 vertical to the upper and lower surfaces;

[0054] In this embodiment, the adjustable support assembly 2 includes a base 21 and a support column 22. The bottom of the support column 22 is fixedly connected to the base 21, and the top is provided with a notch 23 for adjustment. The notch can be in-line, cross Type or polygon, thread 25 is set on the side of support column 22, and said support column 22 is threadedly connected with said through hol...

Embodiment 2

[0066] This embodiment provides a method for preparing the block load-bearing panel as in Embodiment 1, comprising the following steps:

[0067] Prepare the following component raw materials by weight:

[0068] a. 20-30 parts of alkali-free glass fiber, 11-15 parts of calcium powder, 5-10 parts of aluminum hydroxide, 1-3 parts of lanthanum oxide, 2-3 parts of processing aid, 60-70 parts of phenolic modified PPA resin , 15-20 parts of quartz fiber twill fabric, 1.5-2.5 parts of silane coupling agent, 1-2 parts of aluminum hydroxyquinoline, 40-50 parts of bisphenol A cyanate, 1-2 parts of toughening agent, epoxy 10-12 parts of resin, 6-8 parts of polyphenol oxygen resin;

[0069] The phenolic modified PPA resin is composed of m-diethynylbenzene and p-diethynylbenzene ablation phenolic formaldehyde according to the weight ratio of 4:1;

[0070] The toughening agent is a core-shell structure with n-butyl acrylate as the core layer and polymethyl methacrylate-co-acrylamide as the...

Embodiment 3

[0077] This embodiment provides a method for installing the assembled overhead leveling ground as in Embodiment 1, which is characterized in that it includes the following steps:

[0078] a. Clean up the concrete floor sanitation, remove dust, and spray ground solid paint;

[0079] b. Measure the size of the house area, and match the model and quantity of the corresponding block load-bearing panels and adjustable support components according to different area ratios;

[0080] c. Put horizontal lines. On both sides of the front and rear directions of the installation sequence, place a parallel horizontal line according to the preset elevated ground height, draw a sliding horizontal line between the two parallel lines, and move to the non-installation direction in sequence according to the advancement of the installation. slide;

[0081] d. Thread the adjustable support assembly to the block-shaped load-bearing panel, adjust the support assembly through the notch to make the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com