High-precision very-thin special-wide cold-rolled steel band and its working process

A technology of cold-rolled steel strip and processing technology, which is applied in the field of high-precision ultra-thin and ultra-wide cold-rolled steel strip and its processing technology, which can solve the problems of difficult implementation, high cost and high price of cold-rolled strip for enterprises, and reduce production costs , simple manufacturing process, simple post-processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

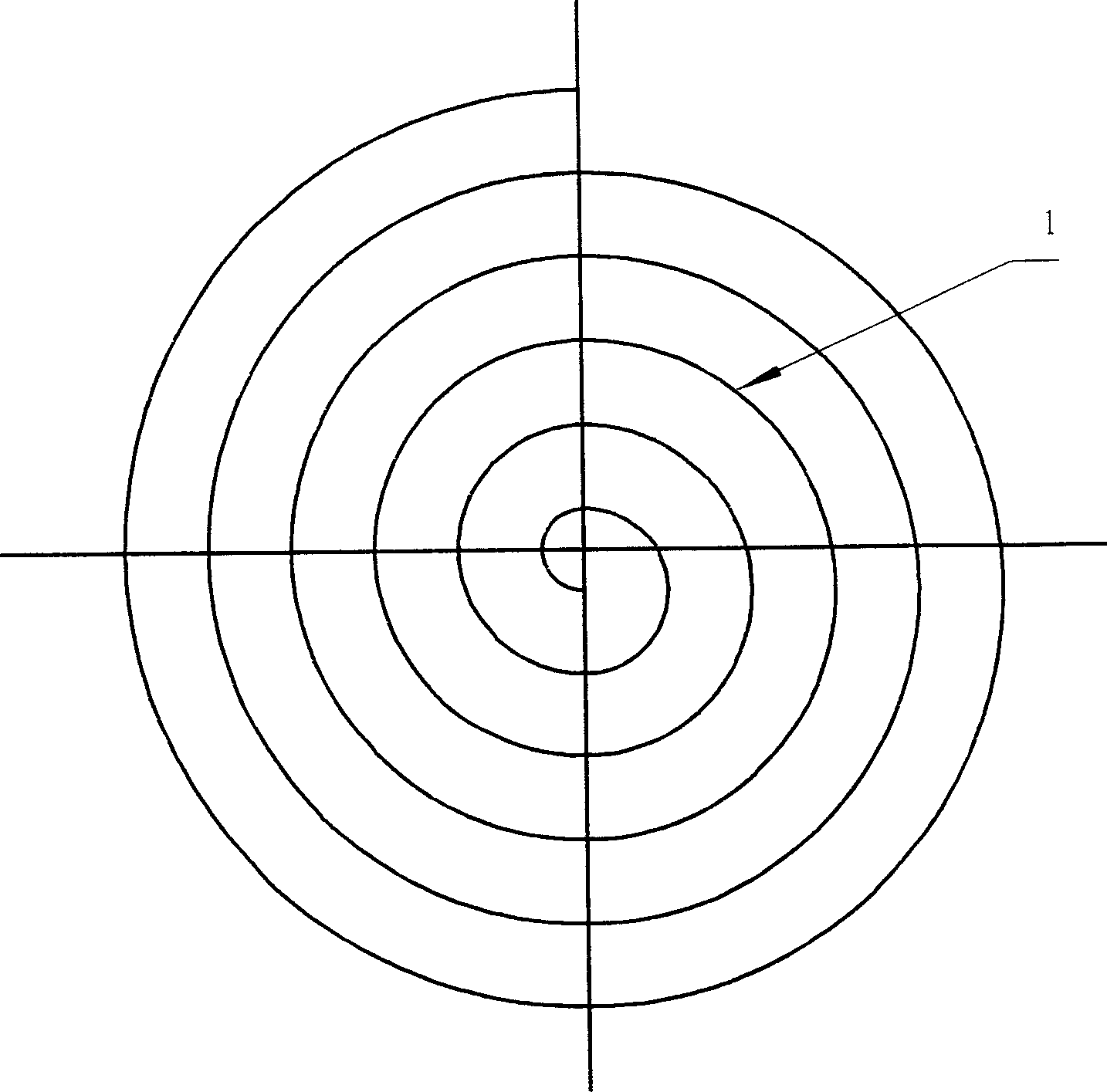

[0018] The present invention selects the hot-rolled strip blank coil material, the thickness is: 1.8-3.2mm, and the length is determined according to the needs of customers. After cold rolling, the thickness of the cold-rolled steel strip 1 is 0.035-0.055 mm, and the width is 100-550 mm.

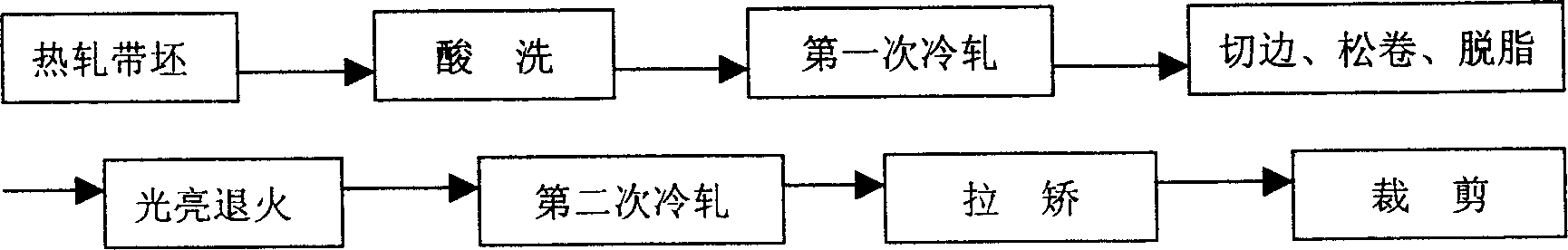

[0019] The present invention adopts following processing steps:

[0020] 1. The raw material of the hot-rolled strip coil is pickled first. The acid pickling medium is an aqueous solution of hydrochloric acid with a concentration of not less than 15%, and the acid solution is heated with steam. The temperature is about 70°C. The washing speed is generally 15 m / min, so that the scale on the surface of the steel strip can be washed off to the greatest extent;

[0021] 2. Select the thickness of the hot-rolled strip in the first rolling process according to the user's requirements for the physical properties of the finished steel strip and the thickness of the final product. The first rolling...

Embodiment 2

[0028] The present invention selects the hot-rolled strip blank coil material, the thickness is: 1.8-3.2mm, and the length is determined according to the needs of customers. After cold rolling, the thickness of the cold-rolled steel strip 1 is 0.035-0.055 mm, and the width is 100-550 mm.

[0029] The present invention adopts following processing steps:

[0030] 1. The raw material of the hot-rolled strip coil is pickled first. The pickling medium is hydrochloric acid aqueous solution with a concentration of not less than 15%, and the acid solution is heated with steam. The temperature is about 75°C. Washing speed, generally 15 m / min;

[0031] 2. The first rolling process is carried out on a four-high rolling mill. Since the thickness of the hot-rolled strip is to be rolled from 1.8-3.2mm to 0.15-0.35mm in the first rolling process, the total reduction rate is over 90%. The first rolling process uses emulsion, the volume concentration of the emulsion is selected as: 4-6%, the...

Embodiment 3

[0038] The present invention selects the hot-rolled strip blank coil material, the thickness is: 1.8-3.2mm, and the length is determined according to the needs of customers. After cold rolling, the thickness of the cold-rolled steel strip 1 is 0.035-0.055 mm, and the width is 100-550 mm.

[0039] The present invention adopts following processing steps:

[0040]1. The raw material of the hot-rolled strip coil is pickled first, and the temperature of the acid solution is heated by steam to about 80°C, and the pickling speed is generally 15 m / min;

[0041] 2. The first rolling process is carried out on a four-high rolling mill. Since the thickness of the hot-rolled strip is to be rolled from 1.8-3.2mm to 0.15-0.35mm in the first rolling process, the total reduction rate is over 90%. The first rolling process uses emulsion, the volume concentration of the emulsion is selected as: 4-6%, the pH value is: 7, the thickness of the hot-rolled strip is rolled to 0.15-0.35mm thick after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com