Modular decking planks

a technology of modular decking and planks, applied in the direction of walls, flooring, treads, etc., can solve the problems of relatively high material cost, relatively long installation time, and stress risers, and achieve the effect of convenient assembly and inexpensive manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

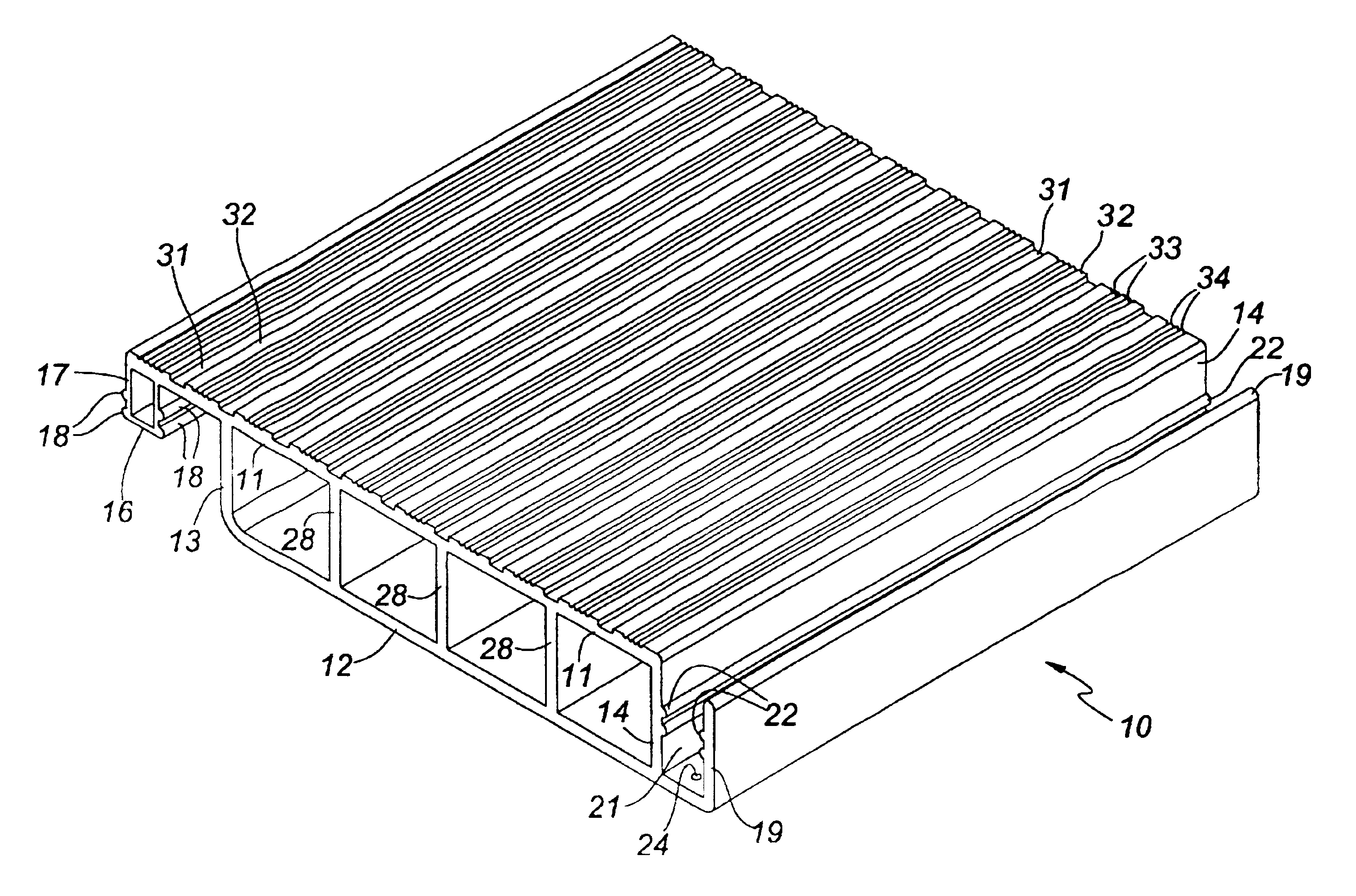

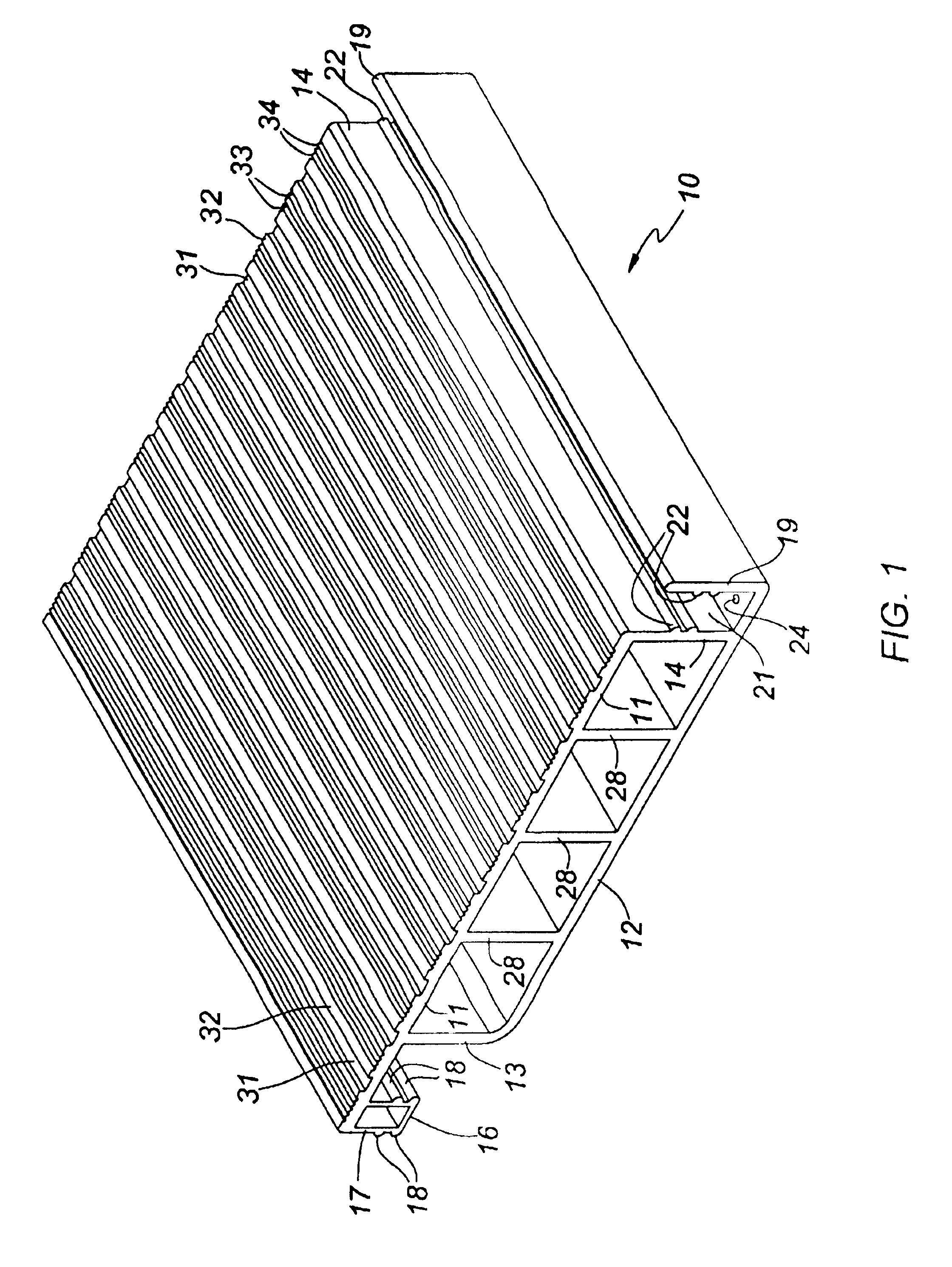

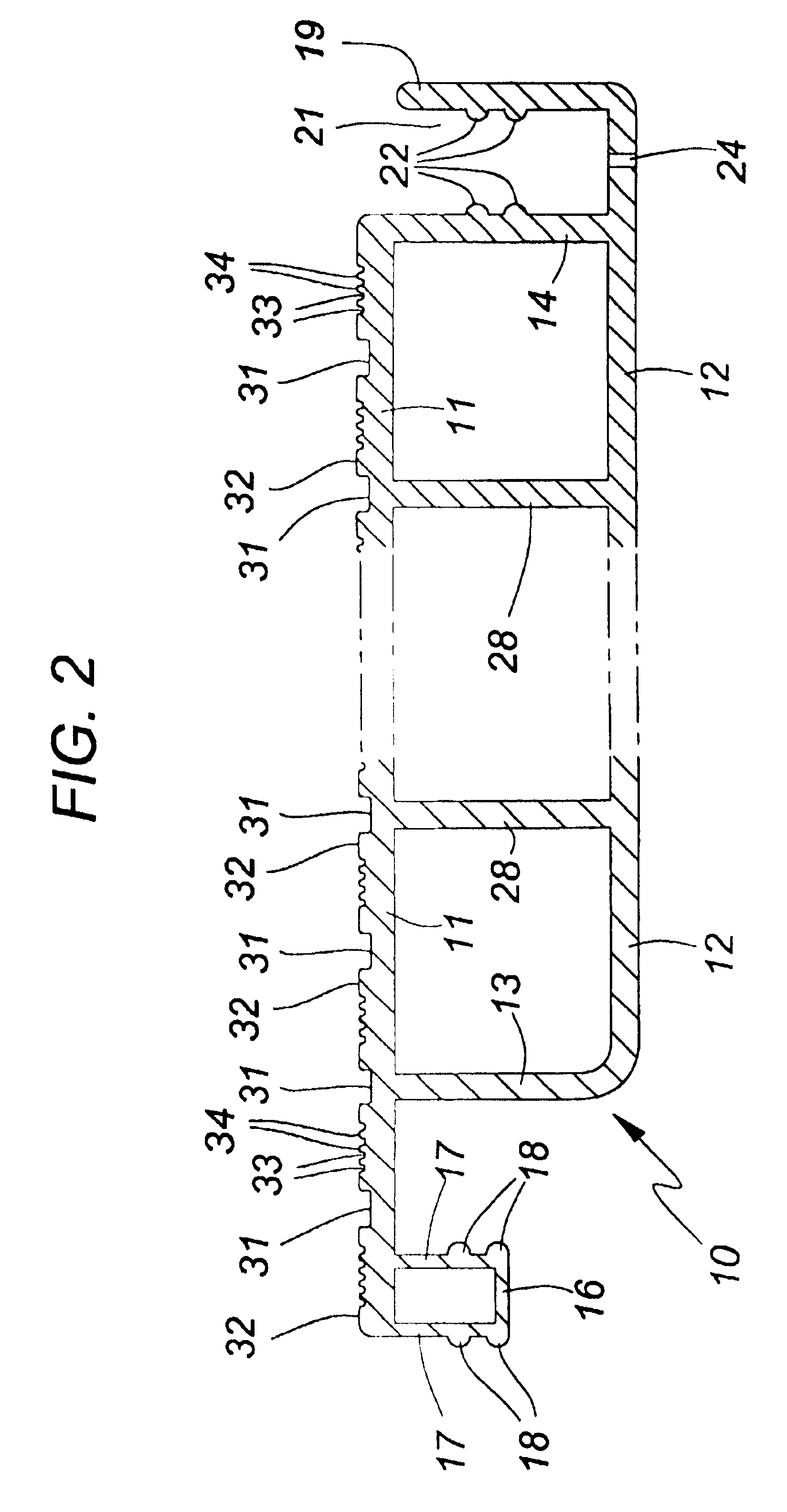

[0021]Referring to the drawings for a clearer understanding of the invention it may be seen in FIG. 1, that the invention contemplates an elongated extruded construction element 10 having a top wall portion 11, a bottom wall portion 12, a first side wall 13 connecting the top and bottom, a second side wall 14 connecting the top and bottom. The element 10 is preferentially extruded from PVC or some other suitable plastic; however, aluminum extrusion of the plank is also possible.

[0022]Top wall portion 11 extends laterally past first side wall 13 and terminates in a downwardly extending flange 16 which includes a pair of flange walls 17 on which a set of longitudinally extending ribs 18 are formed in spaced relation to one another. Bottom wall portion 12 extends laterally past second side wall 14 and terminates in an upstanding longitudinal wall 19 that forms an upwardly opening channel 21. Formed on second side wall 14 and upstanding longitudinal wall 19 within channel 20 are complem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com